The look is pretty similar to before, but instead of paint, it's now is laminated. I'll post pics when it's finished.larrycavan wrote:Got pics of the front side?

Not the Mercdog again

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

More pictures, if anyone is interested.

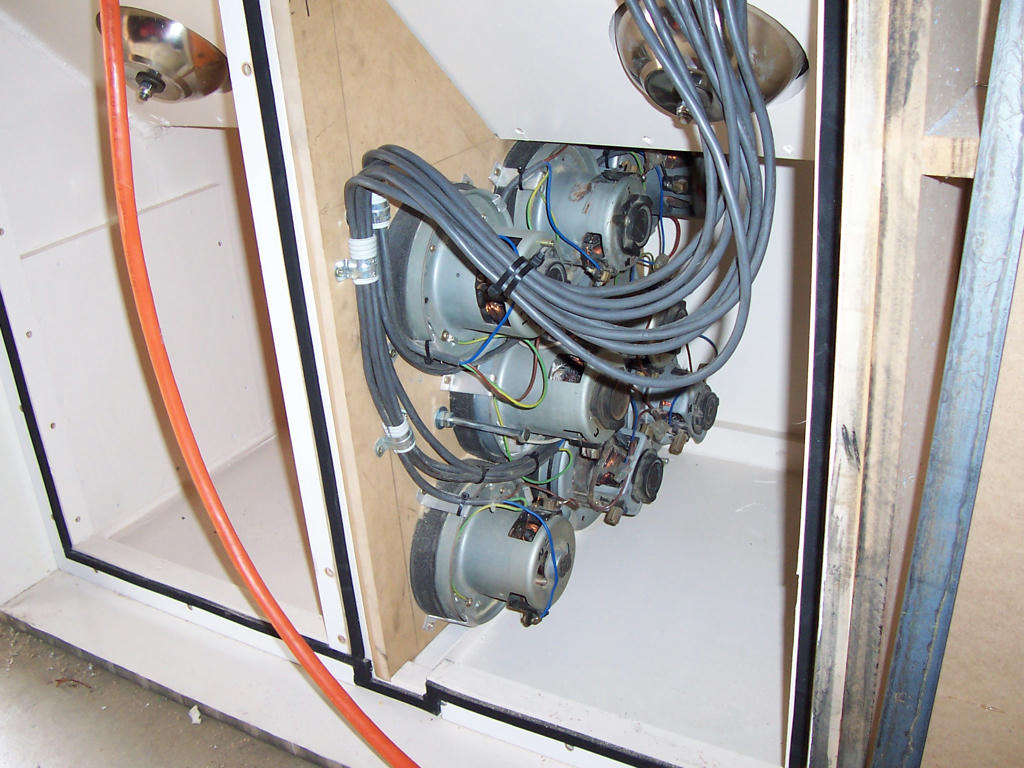

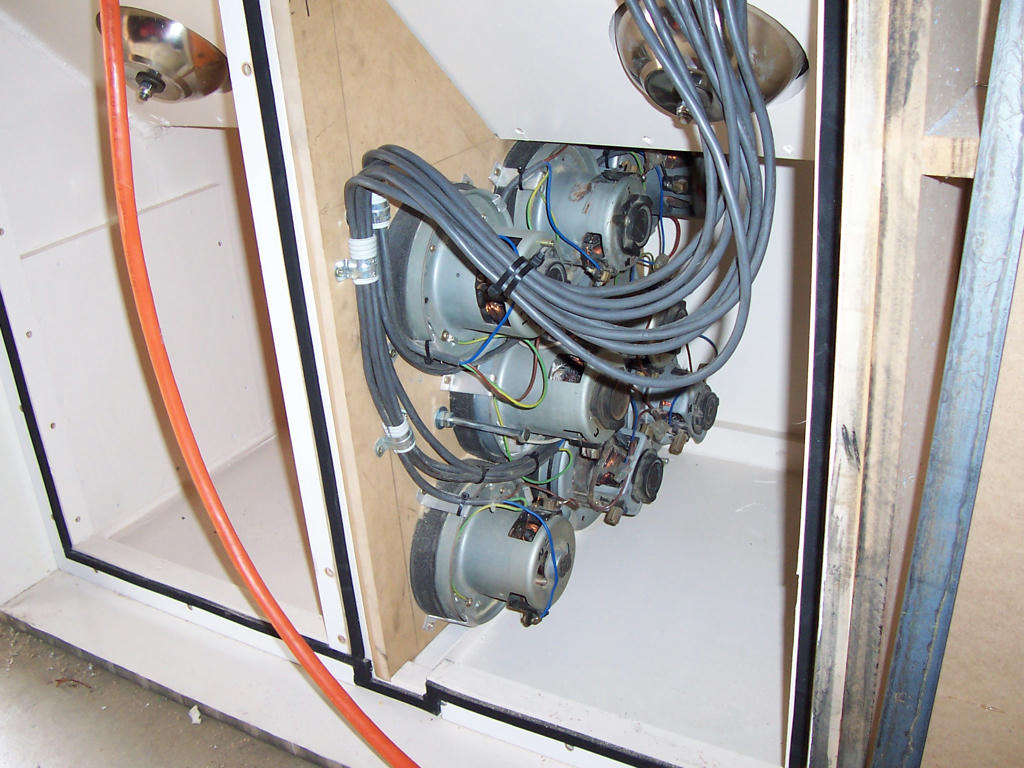

Because the engine compartment hadn't been started when I got the bench and the fact that the motors were used - who knows how long they will last -, I copied the slide out motor board for easy motor changes.

Because the engine compartment hadn't been started when I got the bench and the fact that the motors were used - who knows how long they will last -, I copied the slide out motor board for easy motor changes.

-

larrycavan

- Posts: 235

- Joined: Tue Mar 09, 2010 9:46 pm

Re: Not the Mercdog again

Looking Good

I toasted a motor recently in mine. Prior to you posting on this project I had ZERO interest in working on my bench. NOW, I think as soon as I get work all caught up I'm diving in and make some changes that you inspired A slide out motor board will be one of them and I think adding two motors as well....

A slide out motor board will be one of them and I think adding two motors as well....

I toasted a motor recently in mine. Prior to you posting on this project I had ZERO interest in working on my bench. NOW, I think as soon as I get work all caught up I'm diving in and make some changes that you inspired

Larry C

http://www.cavanaughracing.com

http://www.cavanaughracing.com

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

Working on a SF600 I noticed there isn't much room to change motors - if one blows at the back you have to take out all the motors in front of it - so I copied the slide out board from someone on here. I still have to add the handles to the board, because the board sticks sometime.

This project is becoming a love hate thing, because I'm putting in a lot of hours that I'm not getting paid for, but at least it's going to be half decent when it's finished.

I was going to fire it up this week but I had a setback, so hopefully next week we will see if it works.

Everyone testing at higher depressions makes me feel inadequate, like I'm leaving something on the table, so adding more motors might produce something interesting.

This project is becoming a love hate thing, because I'm putting in a lot of hours that I'm not getting paid for, but at least it's going to be half decent when it's finished.

I was going to fire it up this week but I had a setback, so hopefully next week we will see if it works.

Everyone testing at higher depressions makes me feel inadequate, like I'm leaving something on the table, so adding more motors might produce something interesting.

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

I got all the parts to dummy up the front.

Now I have to make it work.

Now I have to make it work.

-

Brucepts

- Site Admin

- Posts: 1867

- Joined: Fri Jan 08, 2010 3:35 pm

- Location: Pennsylvania

- Contact:

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

I'm officially stumped.

I put the PAP 100cfm plate on top - sharp edge up bevel down for intake - the PAP 300 cfm plate inside - sharp edge up bevel down for intake - and I get 115 cfm - 15 over - in the intake vacuum mode. I then flip the plates and test in exhaust pressure mode and get 75 cfm - 15 under -.

This now looks like a leak in the top chamber equivalent to a 3/8" hole - unless the FP1 is reading wrong -, so I test the chambers. I block the internal PAP 300 cfm and feel around inside the top chamber and the outside of the lower chamber with the motors running in exh and producing 30" in the lower chamber. Nothing - I did it 3 times -. Next I open the lower PAP 300 cfm and block the top PAP 100cfm plate and check the outside for leaks. Nothing.

I was just about to give up finding the leak when I noticed the FP1 was still reading pressure, but slowing dropping, after the motors were shut off. I started the motors and turned them off again, and even after they had stopped spinning the FP1 pressure was still creeping slowly down from 10". I then opened the flowbench intake control valve to see if the pressure was trapped in the chambers, and the pressure reading from the FP1 dropped instantly. I tried it again, and again it showed trapped pressure inside the flowbench. This kind of proves that the bench has no leaks, unless you guys can think of something, and if you're wondering why the pressure didn't fall instantly with the exh control valve open during this test, all I can think of is that the valve was only open a small amount, and that the bowls are so flexible, that the air pressure forced it against the seal so well, that it was basically closed.

If any of you brains have any ideas to the +15 - 15, I could use some advice.

Other problems are :-

The bowls are so flexible on the bottom that the screw doesn't provide good control - the bowl gets stuck to the seat and they suddenly pop open when you turn the screw -. I'm going to try a metal disk washers sandwiching the bowl bottoms so they can't flex.

The motors scream when in exh mode - the back valve is open on the motor side so the noise comes out very loudly from these old motors -.

The intake control valve screeches at certain point when you open it.

The inspection ports aren't rated for high pressures - luckily I was behind the machine when the lid blew off because it's at jewel height LOL -. I didn't realise 2 motors would make so much pressure - I assumed the motor chamber would be very inefficient with lost of leaks -, so now I afraid of getting 8 motors running.

Numbers fluctuating 1 cfm on the FP1 - I will try 0.040" restrictors in FP1 tubes -.

I put the PAP 100cfm plate on top - sharp edge up bevel down for intake - the PAP 300 cfm plate inside - sharp edge up bevel down for intake - and I get 115 cfm - 15 over - in the intake vacuum mode. I then flip the plates and test in exhaust pressure mode and get 75 cfm - 15 under -.

This now looks like a leak in the top chamber equivalent to a 3/8" hole - unless the FP1 is reading wrong -, so I test the chambers. I block the internal PAP 300 cfm and feel around inside the top chamber and the outside of the lower chamber with the motors running in exh and producing 30" in the lower chamber. Nothing - I did it 3 times -. Next I open the lower PAP 300 cfm and block the top PAP 100cfm plate and check the outside for leaks. Nothing.

I was just about to give up finding the leak when I noticed the FP1 was still reading pressure, but slowing dropping, after the motors were shut off. I started the motors and turned them off again, and even after they had stopped spinning the FP1 pressure was still creeping slowly down from 10". I then opened the flowbench intake control valve to see if the pressure was trapped in the chambers, and the pressure reading from the FP1 dropped instantly. I tried it again, and again it showed trapped pressure inside the flowbench. This kind of proves that the bench has no leaks, unless you guys can think of something, and if you're wondering why the pressure didn't fall instantly with the exh control valve open during this test, all I can think of is that the valve was only open a small amount, and that the bowls are so flexible, that the air pressure forced it against the seal so well, that it was basically closed.

If any of you brains have any ideas to the +15 - 15, I could use some advice.

Other problems are :-

The bowls are so flexible on the bottom that the screw doesn't provide good control - the bowl gets stuck to the seat and they suddenly pop open when you turn the screw -. I'm going to try a metal disk washers sandwiching the bowl bottoms so they can't flex.

The motors scream when in exh mode - the back valve is open on the motor side so the noise comes out very loudly from these old motors -.

The intake control valve screeches at certain point when you open it.

The inspection ports aren't rated for high pressures - luckily I was behind the machine when the lid blew off because it's at jewel height LOL -. I didn't realise 2 motors would make so much pressure - I assumed the motor chamber would be very inefficient with lost of leaks -, so now I afraid of getting 8 motors running.

Numbers fluctuating 1 cfm on the FP1 - I will try 0.040" restrictors in FP1 tubes -.

-

RACEPUMPER

- Posts: 447

- Joined: Wed Aug 25, 2010 7:54 am

- Location: Riverina Australia

Re: Not the Mercdog again

Watch out for the family jewells.......Old Grey wrote: luckily I was behind the machine when the lid blew off because it's at jewel height LOL -.

You haven't got water gauges to compare to? Also blow out the hoses, I had a slight blockage in one of mine and it was reading high and low like that.

Have you played with different CD values?

Jim

I really love making stuff but don't finish much

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

I'm scared of this thing, and will probably fit a blow-off valve similar to a blown set-up, but set a 36".RACEPUMPER wrote:Watch out for the family jewells.......Old Grey wrote: luckily I was behind the machine when the lid blew off because it's at jewel height LOL -.

You haven't got water gauges to compare to? Also blow out the hoses, I had a slight blockage in one of mine and it was reading high and low like that.

Have you played with different CD values?

Jim

Should I just change the cd until the figure is right - I'm using the PAP 300cfm@28", 2.045, 0.62 plate figures for the internal -

The kicker this morning is that I hooked up my other FP1 and it reads 30cfm low, where as the bench FP1 reads 15cfm high, also the bench one doesn't seam to be able to switch between pitot or orifice - it is what it is, whatever that is -. Each FP1 has it own hoses, but I will blow out the brass tubes in the machine in case a mud wasp has been there.

Thanks

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

It looks like the FP1s are screwed.

With the PAP 100 cfm on top and the 300 cfm inside, @ 28"

the bench FP1 reads 4.4" - 118cfm -

my FP1 reads 1.64" - 60 cfm -, which might be accountable that the tube ends are leaking because they feel a bit loose.

and the water U-tube reads approx 3.25" - about 102cfm on the spreadsheet -, which is correct

With the PAP 100 cfm on top and the 300 cfm inside, @ 28"

the bench FP1 reads 4.4" - 118cfm -

my FP1 reads 1.64" - 60 cfm -, which might be accountable that the tube ends are leaking because they feel a bit loose.

and the water U-tube reads approx 3.25" - about 102cfm on the spreadsheet -, which is correct