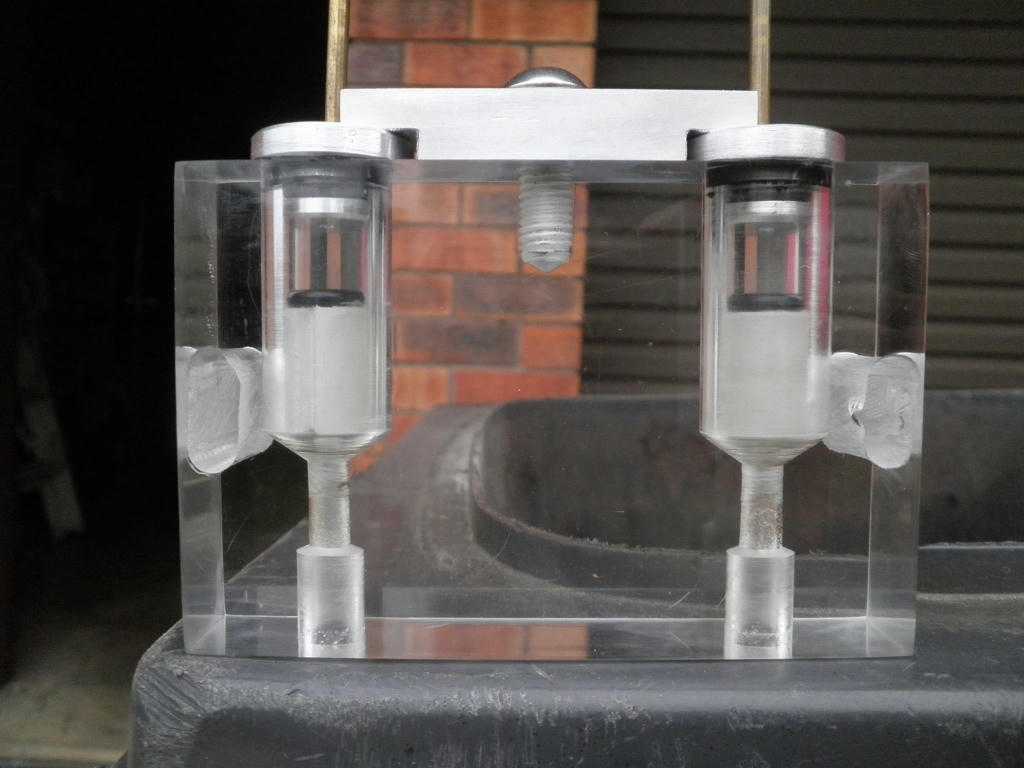

The setup is a 1mm stainless steel orifice disk with 0.020" clearance spinning between 2 6mm alum disks.Old Grey wrote:

It spun well enough, but had uneven gaps all around the orifice plate - you can see them in the 2nd pic -.

Next I took the clearance gap down to 0.004" to force the gaps smaller, but the disk would gall the alum constantly jam on the swarf.

The ss orifice disk looked pretty wavy so we went for 1.2mm, in the hope that the flatter disk would put less pressure on the alum and not gall it.

I also got rid of the top alum plate and just ran the ss disk on the bottom alum plate only.

The disk would spin, but would eventually feel rough.

Upon disassembly I saw that the ss disk was still picking up alum and galling, and that means that ss is not compatible with alum when rubbing.

I came up with a fix where there is protruding brass ring inserts in the flow through holes and ball bearings embedded in the alum plates so that the ss disk never touches alum. But when I checked the flatness of the alum plates, I found out they were heavily warped (0.050")

I worked out that the alum plate is cold rolled and that the surfaces are in compression, so that when I specified the fancy scallops in the undersides, it relived the stress on one side and buckled the plates quite badly.

A bit of advice for people who don't have laser cutting experience. No one can actually predict warpage with thickness, because it's shape dependant - my disk is more warped near the small holes than the large holes -. You can touch a plate right after it's cut, and it's only warm, but laser is concentrated heat, so it will still warp thin plates. Also the person cutting has a different interpretation of how much warp is warped - I told him to use a thickness that wouldn't warp, and even though he thought the 1.2mm wasn't warped, it was warped more than I wanted -. If I was to guess I would say the SF600 disk couldn't be thinner that 1.5mm - their SF1020 test plate is 1.5mm -, or that the warpage in a 1.5mm plate is acceptable.