tvr plenum testing

-

ivanhoew

- Posts: 954

- Joined: Wed Feb 16, 2011 5:12 am

- Location: oxford ,england .

tvr plenum testing

medusa assembled..first drive

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

-

damunk

- Posts: 75

- Joined: Sat Oct 03, 2015 1:38 pm

Re: tvr plenum testing

Still trying to figure out why such a big increase of 25-30%

-

ivanhoew

- Posts: 954

- Joined: Wed Feb 16, 2011 5:12 am

- Location: oxford ,england .

Re: tvr plenum testing

Damunk,

it is because i have stopped the swirling air running straight into the incoming air , so there is less pressure at the point of entry.

i must admit to being a little suprised too.

it is because i have stopped the swirling air running straight into the incoming air , so there is less pressure at the point of entry.

i must admit to being a little suprised too.

medusa assembled..first drive

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

-

Malvin

- Posts: 451

- Joined: Sat Feb 27, 2010 12:50 am

- Location: Pennsylvania

Re: tvr plenum testing

Nice video Robert

I like the 2" disk Idea to help stop the air from swirling

I like the 2" disk Idea to help stop the air from swirling

-

ivanhoew

- Posts: 954

- Joined: Wed Feb 16, 2011 5:12 am

- Location: oxford ,england .

Re: tvr plenum testing

thanks Malvin . in the end i used a inch thick piece of nylon ,about 55mm diameter to get the best effect .i sacrificed a bit of flow to get the best distribution . but 380 cfm , should be enough for my 3.5 litre engine that would need flow for around 220 bhp nat asp.

medusa assembled..first drive

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

-

RACEPUMPER

- Posts: 447

- Joined: Wed Aug 25, 2010 7:54 am

- Location: Riverina Australia

Re: tvr plenum testing

Is it still Turbocharged Robert?ivanhoew wrote: but 380 cfm , should be enough for my 3.5 litre engine that would need flow for around 220 bhp nat asp.

Jim

I really love making stuff but don't finish much

-

ivanhoew

- Posts: 954

- Joined: Wed Feb 16, 2011 5:12 am

- Location: oxford ,england .

Re: tvr plenum testing

hi jim , yes still turbo , i took out the small one and just left the big one in there . its now on the rd after 9 years in the shed.

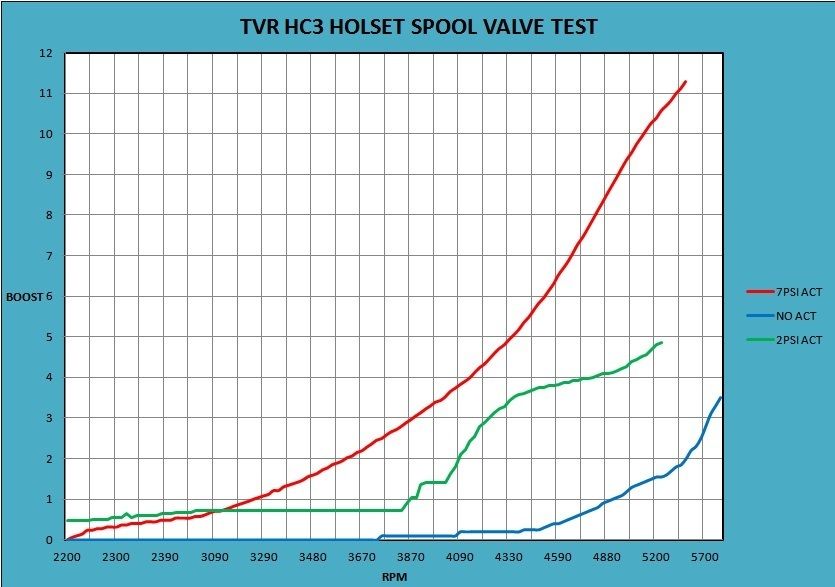

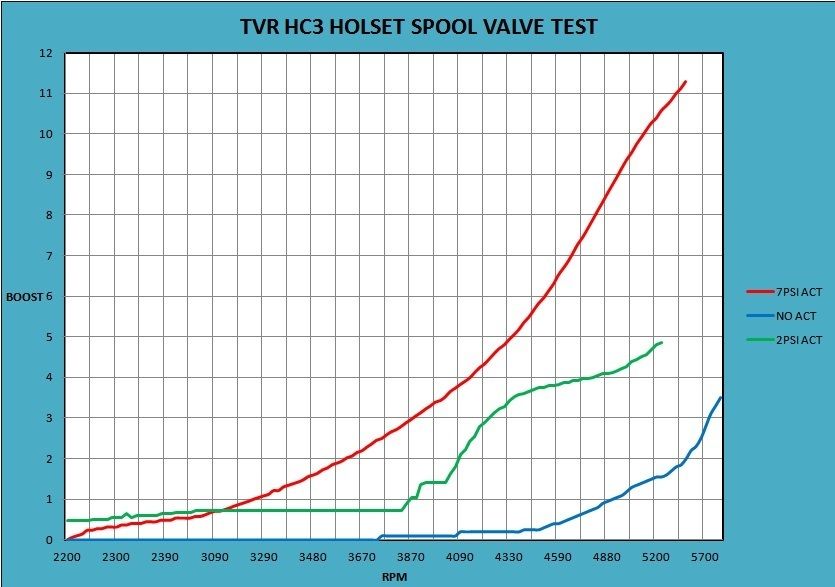

i made a spool valve for it ..

and this is the effect it had on the boost,

not really good enough , so at some point i will put a smaller 60mm turbo on it .

but its now time for me to get back to the garage roof ,and medusa i think .

robert

i made a spool valve for it ..

and this is the effect it had on the boost,

not really good enough , so at some point i will put a smaller 60mm turbo on it .

but its now time for me to get back to the garage roof ,and medusa i think .

robert

medusa assembled..first drive

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

-

ivanhoew

- Posts: 954

- Joined: Wed Feb 16, 2011 5:12 am

- Location: oxford ,england .

Re: tvr v8 215 ci development

New experiment to use the flow bench to compare spooling characteristics between turbos for the tvr .

i really don't want to cut out loads of 1/2 inch plate etc and weld it all up to find it doesn't spool any better than the one i took off ,which is the one on the flow bench there .

i will make a inch nozzle for the compressor outlet ,and a tapping in the side for the pressure drop feed to the flowquick ,then i can compare turbo's using a flow and pressure based graph , should be good ..

medusa assembled..first drive

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

-

ivanhoew

- Posts: 954

- Joined: Wed Feb 16, 2011 5:12 am

- Location: oxford ,england .

Re: tvr plenum testing

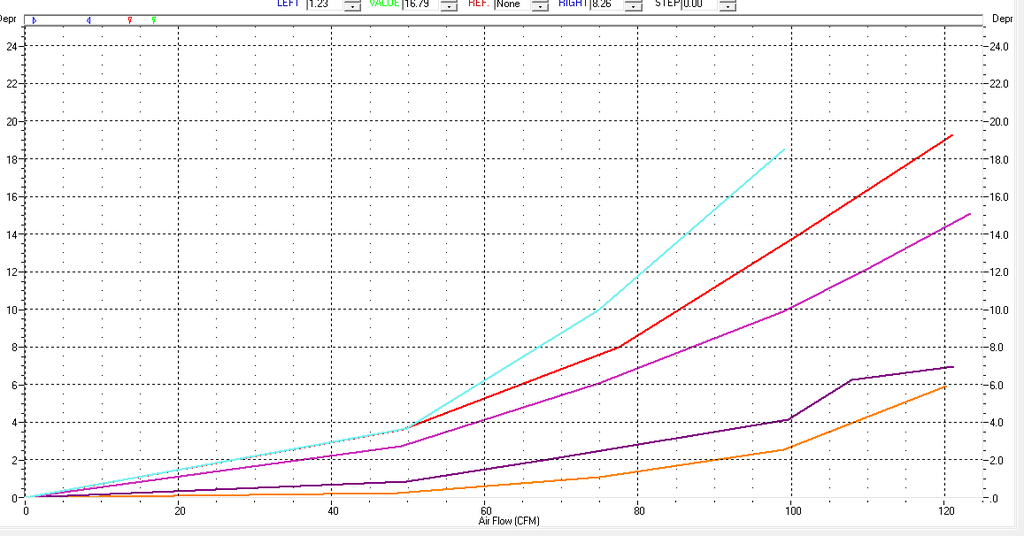

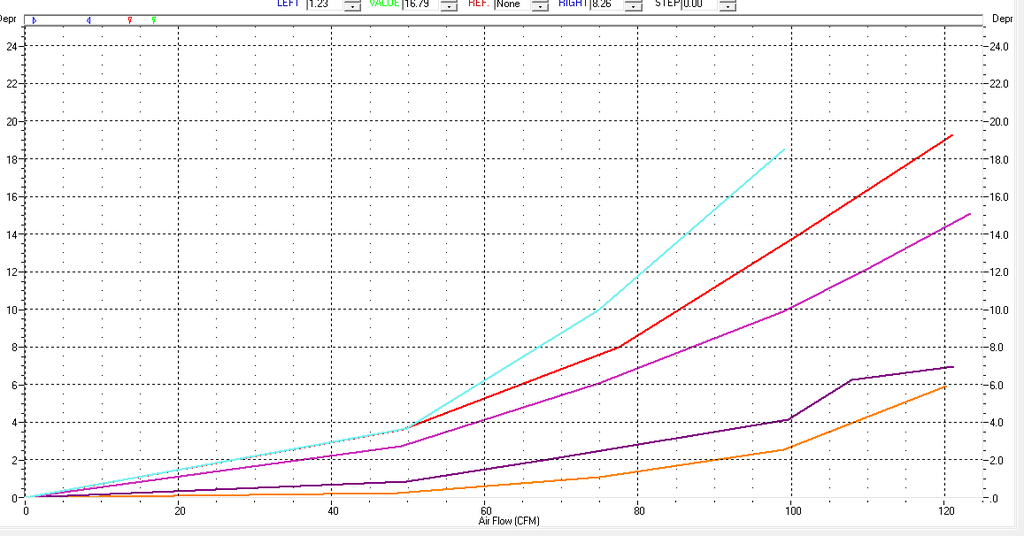

well looks like my new hx50 , is little better than my old hc3-8 holset , ...time for the hx40 to take the stage ...here's a couple of graphs , from the bottom line we have first is the hc8 then hx50 and then hx40 with a 19cm turbine housing and than a hx40 with a 16 cm on there ... oh and then the little IHI for reference...

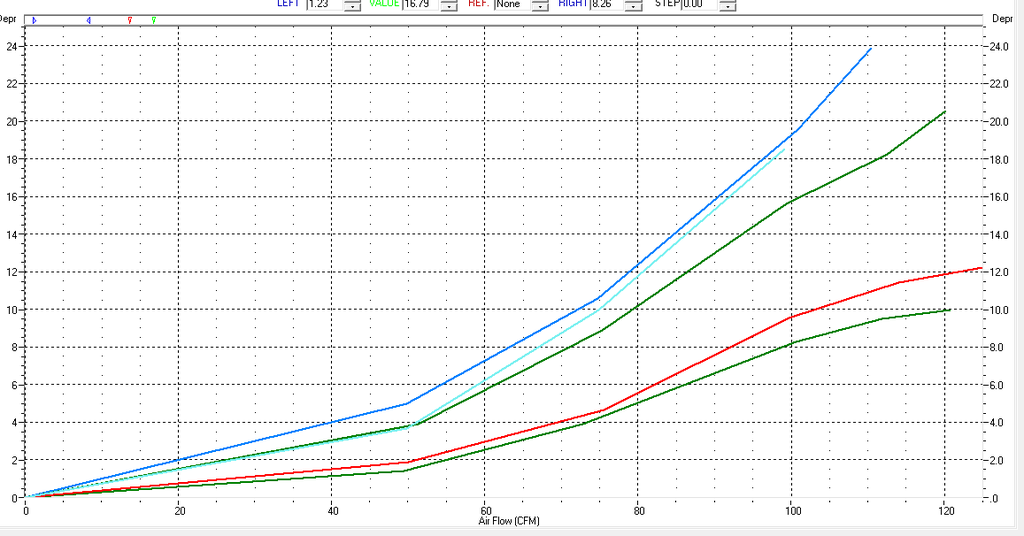

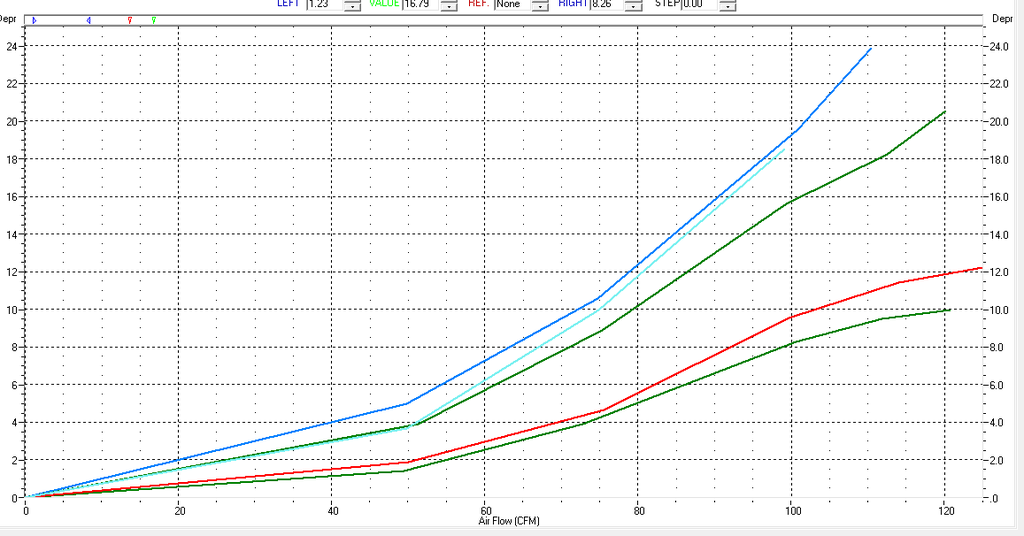

then i blocked one port on the turbine housing of each turbo ,compared to the IHI in light blue you can see it makes quite a difference ...

turbos are in the same order as first graph ,just different colours apart from the IHI.

the holset hx40 16 cm housing is outspooling the little IHI ! which used to come on pretty bloomin hard in the tvr .

regards

robert

then i blocked one port on the turbine housing of each turbo ,compared to the IHI in light blue you can see it makes quite a difference ...

turbos are in the same order as first graph ,just different colours apart from the IHI.

the holset hx40 16 cm housing is outspooling the little IHI ! which used to come on pretty bloomin hard in the tvr .

regards

robert

medusa assembled..first drive

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

https://www.youtube.com/watch?v=zKMvQQm7Cn4&t=5s

-

Tony

- Posts: 1452

- Joined: Wed Mar 03, 2010 3:40 pm

- Location: Melbourne, Australia

Re: tvr plenum testing

Robert, I tried something like this myself many years ago, blocking off one half of a twin scroll turbine housing.

What happened for me, was that the turbine back pressure increased far more than the boost increased, creating so much exhaust reversion that it hurt spooling rather than helping.

Its not the same as just fitting a much smaller turbo. With a small turbo, the turbine is still fairly well matched for rpm and torque requirements of the compressor.

By blocking half the turbine that totally screws up the turbine/compressor matching, and the results are not the same as with a smaller turbo.

Try plotting turbine inlet pressure against developed boost pressure, and see how that goes.

Heaps of low end boost is good, but not if it also creates massive exhaust back pressure to get it.

I had exactly the same problem with trying to control a movable vane Garrett VNT turbo. I just could not get high boost with low exhaust back pressure when closing down the vanes.

Anyhow, its an interesting experiment.

What happened for me, was that the turbine back pressure increased far more than the boost increased, creating so much exhaust reversion that it hurt spooling rather than helping.

Its not the same as just fitting a much smaller turbo. With a small turbo, the turbine is still fairly well matched for rpm and torque requirements of the compressor.

By blocking half the turbine that totally screws up the turbine/compressor matching, and the results are not the same as with a smaller turbo.

Try plotting turbine inlet pressure against developed boost pressure, and see how that goes.

Heaps of low end boost is good, but not if it also creates massive exhaust back pressure to get it.

I had exactly the same problem with trying to control a movable vane Garrett VNT turbo. I just could not get high boost with low exhaust back pressure when closing down the vanes.

Anyhow, its an interesting experiment.

Also known as the infamous "Warpspeed" on some other Forums.