Larry,

I see where you are gong and yes I agree with your perspective, I am a little more opinionated and would not want to correct for error just to match the so called standard of the industry. We already know that the SF orifice plate is not precision and could be a major factor in this phenomenon as it is proven that the air going through the orifice must be laminar for it to function properly. Now I know Bruce fools with square edge plates with his bench, would it not be a simple test to produce an orifice of similar size to an SF range 4 or 5 and once bored to size offset it .005 to.015 so we have a shape similar to one that was measured in an SF. With this plate Chad could then use it in his PTS bench flow the same head on both benches in the same range and compare linearity of flow. IMO this would point to or even confirm if it is orifice/CD related or Box/Air flow related.

Thoughts

Rick

Oh and your point of hitting a wall or flow going backwards on one bench and not the other is quite eye opening.

SF Sizes

-

Chad Speier

- Posts: 139

- Joined: Mon Jul 26, 2010 7:48 pm

- Contact:

Re: SF Sizes

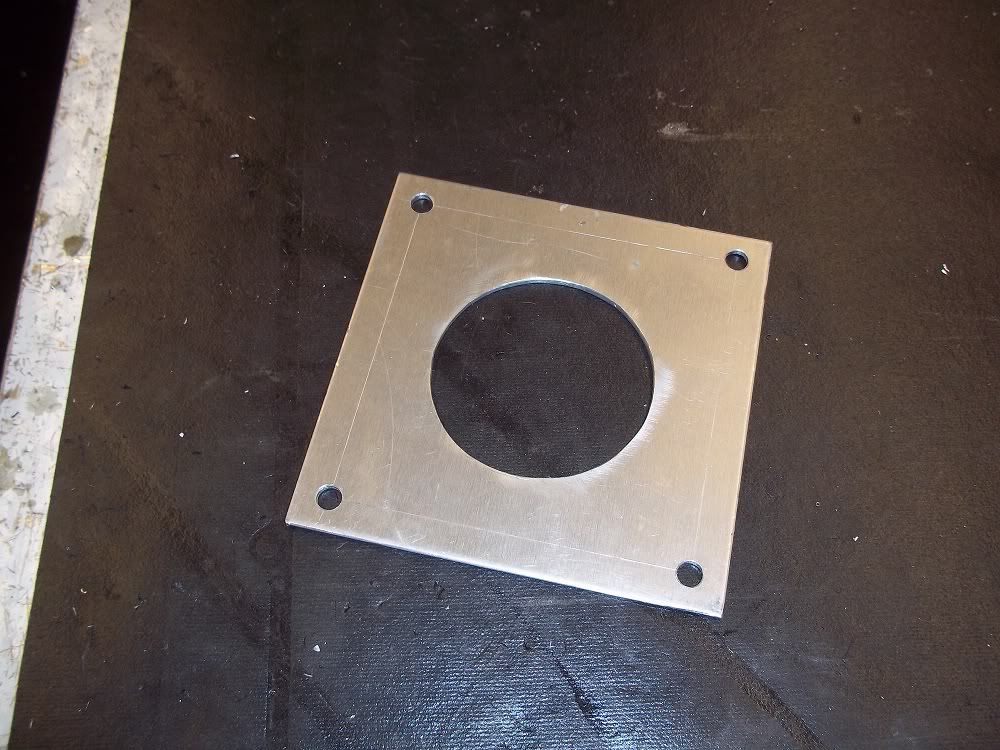

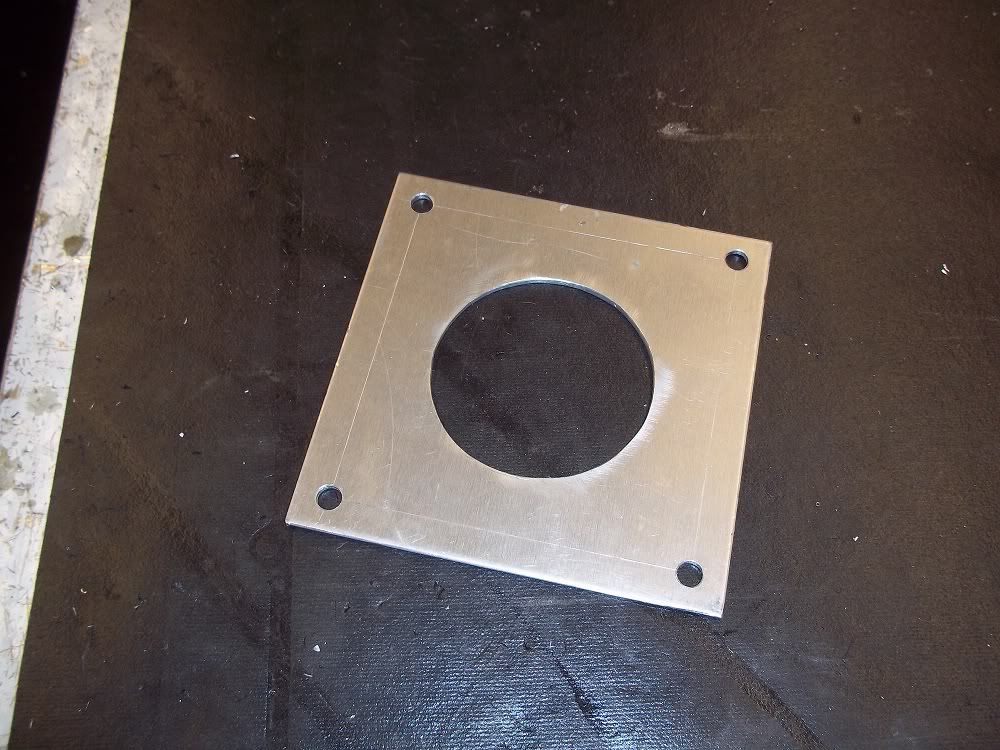

I actually have a square edge 3.200 plate I made. What I found early on was the plate was turbulent with the FP. Maybe with the PTSDM it will be more stable because of the 16" range.

I will do a test here shortly!!

I will do a test here shortly!!

-

Chad Speier

- Posts: 139

- Joined: Mon Jul 26, 2010 7:48 pm

- Contact:

Re: SF Sizes

Here we go!

SRHv2.50BI/23º SBC head

4.060 Brezenski fixture

1206 Brezenski radius plate

2.055/1.600 valve

Calibration plate = 2.375 plate (2.375x2.375=5.641x13.29=74.96x5.29= 396.6 cfm)

PTSDM w/Sharpe edge 3.200 plate = .605 cd, 396.8 cfm

PTSDM w/Square edge 3.213 plate = .615 cd, 396.8 cfm

LIFT sharp/square

.200 153.4/152.2

.300 204.9/205.3

.400 253.1/253.2

.500 287.4/286.2

.600 303.5/302.6

.700 309.4/308.7

.800 314.8/314.2

.900 324.1/322.7

1.00 328.8/325.2

Superflow SF600 w/factory calibration = #3 149.4, #4 294.9, #5 442.2

Superflow SF600 w/re-calibrated = #3 149.5, #4 298.0, #5 451.8

(Range/Percent) //FAC/RE-cal

.200 (#3/ 98.4)// 147.0/147.1

.300 (#4/ 67.2)// 198.2/200.3

.400 (#4/ 83.4)// 245.9/248.5

.500 (#4/ 96.1)// 283.4/286.4

.600 (#5/ 66.9)// 295.8/302.3

.700 (#5/ 69.0)// 305.1/311.7

.800 (#5/ 70.2)// 310.4/317.2

.900 (#5/ 70.5)// 311.8/318.5

1.00 (#5/ 70.7)// 312.6/319.4

I tried to make this as legit as possible! Nothing fudged, lifted the fixture and put on the other bench.

SRHv2.50BI/23º SBC head

4.060 Brezenski fixture

1206 Brezenski radius plate

2.055/1.600 valve

Calibration plate = 2.375 plate (2.375x2.375=5.641x13.29=74.96x5.29= 396.6 cfm)

PTSDM w/Sharpe edge 3.200 plate = .605 cd, 396.8 cfm

PTSDM w/Square edge 3.213 plate = .615 cd, 396.8 cfm

LIFT sharp/square

.200 153.4/152.2

.300 204.9/205.3

.400 253.1/253.2

.500 287.4/286.2

.600 303.5/302.6

.700 309.4/308.7

.800 314.8/314.2

.900 324.1/322.7

1.00 328.8/325.2

Superflow SF600 w/factory calibration = #3 149.4, #4 294.9, #5 442.2

Superflow SF600 w/re-calibrated = #3 149.5, #4 298.0, #5 451.8

(Range/Percent) //FAC/RE-cal

.200 (#3/ 98.4)// 147.0/147.1

.300 (#4/ 67.2)// 198.2/200.3

.400 (#4/ 83.4)// 245.9/248.5

.500 (#4/ 96.1)// 283.4/286.4

.600 (#5/ 66.9)// 295.8/302.3

.700 (#5/ 69.0)// 305.1/311.7

.800 (#5/ 70.2)// 310.4/317.2

.900 (#5/ 70.5)// 311.8/318.5

1.00 (#5/ 70.7)// 312.6/319.4

I tried to make this as legit as possible! Nothing fudged, lifted the fixture and put on the other bench.

Last edited by Chad Speier on Mon Dec 26, 2011 2:06 pm, edited 1 time in total.

-

larrycavan

- Posts: 235

- Joined: Tue Mar 09, 2010 9:46 pm

Re: SF Sizes

Rick,1960FL wrote:Larry,

I see where you are gong and yes I agree with your perspective, I am a little more opinionated and would not want to correct for error just to match the so called standard of the industry. We already know that the SF orifice plate is not precision and could be a major factor in this phenomenon as it is proven that the air going through the orifice must be laminar for it to function properly. Now I know Bruce fools with square edge plates with his bench, would it not be a simple test to produce an orifice of similar size to an SF range 4 or 5 and once bored to size offset it .005 to.015 so we have a shape similar to one that was measured in an SF. With this plate Chad could then use it in his PTS bench flow the same head on both benches in the same range and compare linearity of flow. IMO this would point to or even confirm if it is orifice/CD related or Box/Air flow related.

Thoughts

Rick

Oh and your point of hitting a wall or flow going backwards on one bench and not the other is quite eye opening.

Your thoughts and mine are pretty much in alignment.

Larry C

http://www.cavanaughracing.com

http://www.cavanaughracing.com

-

larrycavan

- Posts: 235

- Joined: Tue Mar 09, 2010 9:46 pm

Re: SF Sizes

Chad,

T.Y. for the numbers Will crunch some numbers sometime today and post results...possible work arounds....etc. Hope you all had a nice Christmas B.T.W.

Will crunch some numbers sometime today and post results...possible work arounds....etc. Hope you all had a nice Christmas B.T.W.

PS... one thing I see right off he bat is your Cd value. I have never, with either FP or PTS manometers been able to use a Cd that high. Always in the .55 - .57 range.... Nothing to cause alarm....just something I see and will ponder as I go forward...

T.Y. for the numbers

PS... one thing I see right off he bat is your Cd value. I have never, with either FP or PTS manometers been able to use a Cd that high. Always in the .55 - .57 range.... Nothing to cause alarm....just something I see and will ponder as I go forward...

Larry C

http://www.cavanaughracing.com

http://www.cavanaughracing.com

-

1960FL

- Posts: 1340

- Joined: Fri Jan 08, 2010 10:36 pm

- Location: Maryland

Re: SF Sizes

As we can see flow starts to lag on the square edge plate as we move up in flow, this is because the velocity picks up with flow and the turn of the air at the edge becomes more difficult to make thus the Vena Contraca gets smaller. I truly feel it is the Manufacturing process of the plate (out of round), the fact that is is shrouded on each side (sandwiched between plywood) that makes it flow different, Kind of like the PTS bench in exhaust mode.

Rick

Rick

-

jfholm

- Posts: 1628

- Joined: Fri Feb 19, 2010 7:36 pm

- Location: Grantsville, Utah 45 min west of Salt Lake City

Re: SF Sizes

Here is a link that explains how calculate the CD of a sharp edged orifice. Go to the bottom for gases as it is different than fluid. Fluid is non-compressible and air is compressible.

http://en.wikipedia.org/wiki/Orifice_plate

Someone else will need to do this as I am too lazy and stupid

John

http://en.wikipedia.org/wiki/Orifice_plate

Someone else will need to do this as I am too lazy and stupid

John

-

1960FL

- Posts: 1340

- Joined: Fri Jan 08, 2010 10:36 pm

- Location: Maryland

Re: SF Sizes

Chad Speier wrote:How about more "fuel" for this fire!

The exhaust port above flowed on the SF and PTS. The SF used the original calibration markings. The PTS used a 2.054 plate with a .605 cd and all factory settings.

SF #3 hole= 159.6

SF #4 hole= 318.9

4.155 fixture

1 7/8 pipe: 6" long

LIFT SF/PTS

.200 112.7/110.9

.300 161.0/156.5

.400 197.7/195.2

.500 225.4/227.7

.600 241.7/243.6

.700 253.9/253.8

.800 262.7/263.4

.900 267.5/270.4

1.00 271.2/273.6

Chad look at how much closer these numbers are this ;is what i was talking about.

Rick

-

Chad Speier

- Posts: 139

- Joined: Mon Jul 26, 2010 7:48 pm

- Contact:

Re: SF Sizes

I totally agree! You think the Audie software is correcting this with more cd at higher lifts? That was my thought.1960FL wrote:Chad Speier wrote:How about more "fuel" for this fire!

The exhaust port above flowed on the SF and PTS. The SF used the original calibration markings. The PTS used a 2.054 plate with a .605 cd and all factory settings.

SF #3 hole= 159.6

SF #4 hole= 318.9

4.155 fixture

1 7/8 pipe: 6" long

LIFT SF/PTS

.200 112.7/110.9

.300 161.0/156.5

.400 197.7/195.2

.500 225.4/227.7

.600 241.7/243.6

.700 253.9/253.8

.800 262.7/263.4

.900 267.5/270.4

1.00 271.2/273.6

Chad look at how much closer these numbers are this ;is what i was talking about.

Rick

-

1960FL

- Posts: 1340

- Joined: Fri Jan 08, 2010 10:36 pm

- Location: Maryland

Re: SF Sizes

John,jfholm wrote:Here is a link that explains how calculate the CD of a sharp edged orifice. Go to the bottom for gases as it is different than fluid. Fluid is non-compressible and air is compressible.

http://en.wikipedia.org/wiki/Orifice_plate

Someone else will need to do this as I am too lazy and stupid

John

This calculation is a little difficult to work with as the formula is based around an orifice in a pipe and thus you must have some Beta Factor, in our case Beta would be considered “0” and the formula would condense to (6) The formula is only there for creating approximations within Bernoulli's equation and thus they state to use approximations of for the CD of .60 to.75 utilizing a CD of .62 is used for Fully Developed Flow (Laminar through the orifice). Thus in the equation we are not solving for CD but using it to apply to theoretical flow to obtain a valid approximation of actual flow. Since Reynolds Number equates to air condition (Laminar – Transition - Turbulent) one must make an assumption to get started. Yes if we were willing to attempt to calculate the Gas/Viscous Forces we could most likely get a good starting point on the CD mathematically, but other trial and error and reference tables have already given us good approximations.

I am currently writing a paper to post in Flowbench 101 that will walk one through the Regression processes of determining the effective CD of like machined orifice plates starting with the flow calculation based on a CD of .62. I want to wait to post it as I am going to physically walk through the actual process and post the data.

In this process we flow a plate across the curve say 1” to 28” and compare the actual data against the theoretical (Mathematical) we then adjust the CD used in the calculation and in FlowSoft to the new estimate, we repeat. Once we have done one plate we move the internal plate to the calibration point (top of bench) and install a new internal orifice and start over. Our combination of plates is such that at 28” the internal plate should be at or above 50% of the DP scale. At the end of the testing you will have determined the CD that provides the most accurate data across the scale for all plates. This all assumes Fully developed flow across the plate.

Chad sorry to highjack the thread.