Page 15 of 17

Re: Not the Mercdog again

Posted: Thu Aug 21, 2014 8:11 am

by 1960FL

Grey,

Well I made a very rough sharp edge orifice - 3.33" 0.572 cd - and it's pretty much the same.

Just how are you determining what the CD Value is?

Rick

Re: Not the Mercdog again

Posted: Thu Aug 21, 2014 5:08 pm

by Old Grey

1960FL wrote:Grey,

Well I made a very rough sharp edge orifice - 3.33" 0.572 cd - and it's pretty much the same.

Just how are you determining what the CD Value is?

Rick

I just keep adjusting it until it reads what the PAP flows.

That sharp edge orifice is so rough that that I can't actually measure the diameter accurately so It could actually be smaller with a higher cd, which would explain why it's down on dep by 3" when flat out with the 6 motors. The 3mm square edge orifice is 3.33" 0.576 cd

I wish the thing was closer to what it's supposed to be, but that's just what it is.

The 40" FP1 with the old single hole on the end of a tube came out as

A = 2.54" 0.067 int - cal PAP 200cfm

B = 2.54" 0.735 exh - cal PAP 200cfm

C = 3.33" 0.630 int - cal PAP 300cfm

D = 3.33" 0.570 exh - cal PAP 300cfm

Re: Not the Mercdog again

Posted: Tue Mar 31, 2015 11:41 pm

by Old Grey

Re: Not the Mercdog again

Posted: Wed Apr 01, 2015 2:36 pm

by 1960FL

Someone has been hard at work!

Nice

Rick

Re: Not the Mercdog again

Posted: Thu May 07, 2015 6:18 pm

by Old Grey

Re: Not the Mercdog again

Posted: Tue May 12, 2015 6:28 am

by larrycavan

Now you're going to wander into the inaccuracies of manometer well bore problems....and you thought the digital stuff was maddening

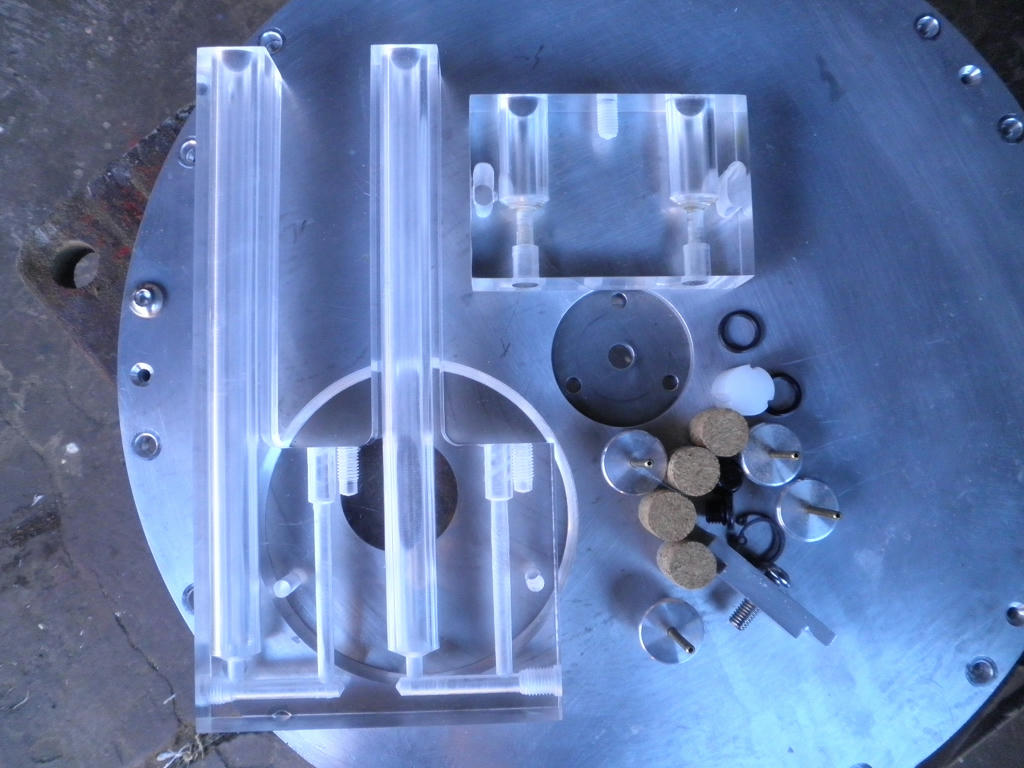

....just kidding. There's a very simple way to verify the FP1 port readings... eventually you'll stumble upon it.... LIKING that rotating orifice disk a lot

Re: Not the Mercdog again

Posted: Tue May 12, 2015 5:32 pm

by Old Grey

The thing has turned to sh!t, so I'm pretty much over it - hence why there is no text with the pics -.

The FP-1 isn't good enough to do the pre head leakage test with a large orifice, so I asked PTS DM users to do a 30 sec test to prove that it can do what I want before I bought it. No one would help me so the information never came, and I had to go back to multiple orifice disk.

The guy making the disk doesn't understand what I want, so it didn't work. I said the disk had to be totally flat, but he gets them laser cut so they are warped. There is so much warp that the disk presses on the Alum so hard when you spin it, it gauls the Alum resulting in disk jam when the clearance is only 0.004". After checking we found out the Alum plates are warped to start with, the machined Alum plate wasn't machined flat, and the disk is warped, so I'm changing everything to SF design where the disk is spring loaded down without the top plate.

The manometer will be easy because I'm going to mark the levels using the DM, and then make a ruler to suit.

Re: Not the Mercdog again

Posted: Tue May 12, 2015 7:21 pm

by larrycavan

You're doing two things wrong.

1 - Making everything way, way, way harder than it has to be.

2 - Creating a water manometer scale from a digital unit that is not at all designed for such work.

I'm not going to get into the how & way. You'll just disregard the advice like you have from the beginning of this thread...

11112703_621206208012366_6246338678839623917_n.jpg

Re: Not the Mercdog again

Posted: Wed May 13, 2015 8:32 pm

by Old Grey

I never wanted the manometer, but the owner insisted, so I made that one just for show. It will never be used for any actual accurate measuring, since there is a graphical manometer in the program.

I'm just going the mark the fluid level at rest, 28", and 50", and fudge a scale.

If you look at the old pics and the new pics, you can see that owner added a whole side panel to the cabinet just for the manometer when he took it to get it laminated. I couldn't kill it after that, even though I stated it many times before hand that it wasn't necessary.

I would have bought the PTS DM right off the bat but the owner gave the impression this was a budget job, and I was given advice that the FP-1 would work, but the majority were right that it's just not sensitive enough at low flows with a large orifice. There was no actual empirical proof given so I though it was an opinion, not tested fact, so I went with the guy that had actually done it and said it worked.

Even though this forum has been around a long time, there are still things it doesn't know - There are critical things I found out that have never been discussed -. There is a general disinterest in the forum unless you run a PTS, so outsiders are always going to be on their own to slug it out.

I'm basically the monkey between this forums opinions and the owner wishes, so I'm just engineering around what I have.

Got good advice, got bad, put a in lot of work to test them all and post the results so that others will have empirical stated proof, rather than untested opinion.

Re: Not the Mercdog again

Posted: Wed May 13, 2015 9:07 pm

by Tony

The Forum certainly has been around for a very long time, and it now links a very large number of people with a serious interest in flow bench construction and testing from all around the world.

Over the years, a great deal of thought, experimentation and testing has been carried out by Forum members, and bit by bit, by trial and error, a very solid knowledge base has gradually built up.

Progress in the art of flow bench construction has been continuous, and is STILL moving forward.

You could do a great deal worse than pay some serious attention to the consensus here on the Forum.

None of us individually could have achieved what we as a group have achieved collectively, and its a truly wonderful thing to see evolving, when people freely share and help each other.