Page 3 of 4

Re: Absolute beginner

Posted: Sat Feb 20, 2016 5:08 am

by Ravoll

Thanks Tony,

I've read this many times.I'm trying to understand exactly what whta the readings will be across the delta manometer.Just not sinking in somehow.On top of that, I'm still trying to figure out what orifice to make for the differential measurements.

I don't see how to calculate them from the spreadsheet.

In the "calculate orifice size" block, I enter 250 cfm and come up with an orifice diameter of 3,6".

Now in the "Calculate Flow" block I enter 3,6" Orifice Diameter,and a fictional pressure difference of 1 inch. Discharge coefficient is left unchanged because I have no idea what the coefficient of the 3,6" orifice actually is or will be.

Anyway,now it shows in the "Calculate Orifice" block an orifice size of 4,3 inches.

Quite confusing

Alan

Re: Absolute beginner

Posted: Sat Feb 20, 2016 5:46 pm

by Tony

The choice of differential pressure across the measurement orifice is wide open to individual preference, but both the extremes have problems.

Suppose you design your measurement orifice for a very low pressure drop (say two inches), at the calibrated flow.

The orifice will be quite large, and the air velocity through the orifice relatively low.

The problem with that will be that flow through the orifice will be like a summer breeze, and very sensitive to any of the unavoidable up stream air turbulence inside the flow bench.

The differential pressure will be unsteady, it may very likely to bounce and flutter and it will likely be much more difficult to read, and get consistent repeatable readings from.

That has nothing to do with the manometer type, the problem is right at the orifice.

And it will get worse as you try to measure right down to very low flows and ultra low differential pressures.

It makes design of the insides of the bench bench far more critical. It will require a massive settling chamber volume and a lot of testing of baffle plates and other refinements to get acceptable results, especially at the higher flow ranges where turbulence inside the bench will be highest.

Going to the other extreme, a very small measurement orifice with a high differential pressure drop (say thirty inches) will have massive violence and fury right at the orifice, and a little bit, or even a lot of up stream turbulence will be of no account.

Differential pressures will be both high and very stable and much easier to read over a wide flow range.

Bench design will be much more forgiving, and it will have excellent very steady, and very repeatable results.

All desirable features.

The only problem, and it is a very serious limitation will be the requires horsepower and current to drive the flow bench air blower.

The blower will be working against very high differential pressure, and that will greatly reduce the maximum airflow it can produce for a given amount of electrical power, which is what ultimately limits most of us.

So we choose something in about the middle.

Most of us here have settled on a sixteen inch differential for the measurement orifice which seems to be an excellent compromise, and something around that figure would be a good starting point, bearing in mind the compromise of trading off higher maximum achievable airflow, for more stable performance.

The choice is entirely yours what differential flow measurement reference pressure you decide to design the bench around.

Re: Absolute beginner

Posted: Sun Feb 21, 2016 3:42 am

by Ravoll

Hi Tony,

I think I got it figured out.I was doing it wrong.The 1 inch pressure diff was all wrong.I thought this was to input the pressure difference across the orifice during testing. A foot note states, "Pressure Difference will be your intended 100% or vertical rise on the Inclined manometer". So the pressure diff is the scale being used?

I made a few different trys with 10" and 15" inputs.and this is what I see.

Gravitational constant 32,2 ft/s²

Density of air 0,07484 lb/ft³

Density of water 62,28 lb/ft³

Orifice diameter 1,00 inches

Pressure difference 15,0 WC in inches

Discharge coefficient 0,62

Combined coefficients 17,26395006

Orifice area 0,7854 in²

Flow 52,5 cfm

If I'm interpreting this correctly then a 1" diameter orifice will measure 0 to 52,5 cfm across a 0" to 15" scale.This would make 52,5 cfm my 100% in this scenario.

Alan

Re: Absolute beginner

Posted: Sun Feb 21, 2016 4:21 am

by Tony

Yes, that all sounds about right.

So you take your sloping manometer tube (no matter how long) and mount it so that the high end is 15" above the low end, and the 100% mark at the high end will correspond to 52.5 CFM of flow.

And the zero mark at the low end zero flow.

That is with the 1.00 inch diameter measurement orifice.

Make the sloping manometer tube any convenient length, whatever will fit nicely across the width of the bench.

The longer it is, the easier it will be to read where the percentage divisions become increasingly cramped at the low end.

Re: Absolute beginner

Posted: Sun Feb 21, 2016 4:53 am

by Ravoll

So the angle has nothing to do with it.Its the high low end difference.The reason I ask is,if my tube itself is only 15" long to start with then in order to achieve a high end low/end difference of 15",the tube would be 90 degrees straight up.

But the good news is I got plenty of tubing.

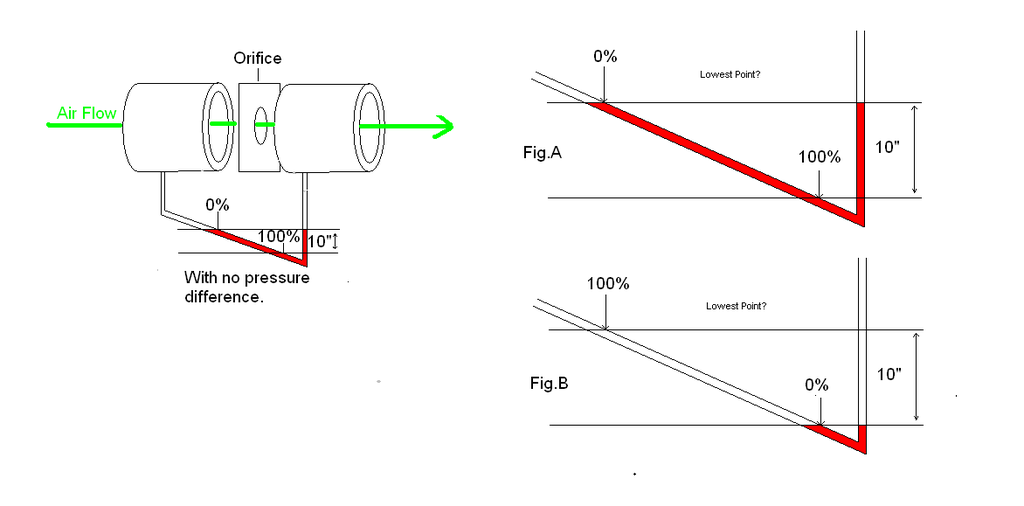

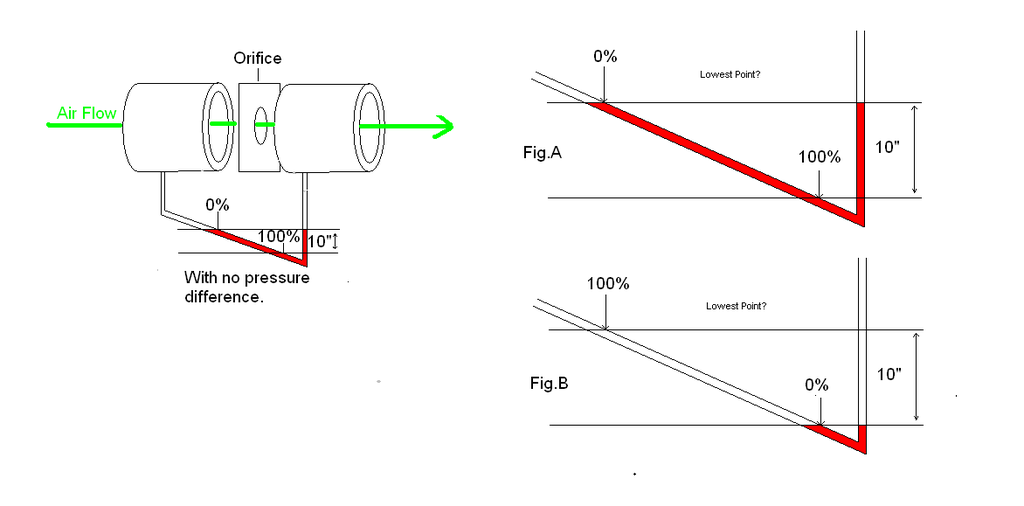

Here is a picture of my intended inclined manometer construction.Tt's just a mock up and will have to be changed.Where could on consider the low end to be with this type of bend?

Alan

Re: Absolute beginner

Posted: Sun Feb 21, 2016 5:20 am

by Tony

So the angle has nothing to do with it.

Yes it the height difference from one end to the other is all that that matters, and only the height difference.

A 15" long vertical manometer would work, but be extremely difficult to read to the required accuracy.

The bore of the tube does not matter either.

The overall length does not matter, and we are not interested in the angle of incline either.

But bear in mind that you will need to mark off the non linear percentage scale, and that will be made a lot easier to do accurately if you use a round number of inches or millimetres for the length of the scale.

Hint... A 1,000mm long scale is probably the easiest to accurately divide and mark off if that length is practical.

One other point to bear in mind with a very long scale, it needs to be dead straight, and keeping the flow bench level becomes far more critical. If you have a bow in the tube, or a wonky concrete floor and the bench is on casters, that can introduce repeatability errors.

If in doubt, screw the manometer to a brick wall where it simply cannot move.

And slightly flexy clear acrylic tube is fine if it sits tightly in a metal channel, or a routed groove that is dead straight.

Even a glass tube can bow slightly, and may need some support.

The more horizontal the manometer tube, the more care that is needed.

A vertical manometer can be out by ten degrees from vertical and it hardly makes any difference.

Not so with a very low angle of slope.

Re: Absolute beginner

Posted: Sun Feb 21, 2016 5:53 am

by Ravoll

I saw a scale for download on the Dtec site I think.If I can get it 1:1 I could use that as my base and build around it.

Most inclined manometers I've seen are sharp angled.This what I have isn't, as seen in the photo.How would you determine the lowest point for what I have?

Alan

Re: Absolute beginner

Posted: Sun Feb 21, 2016 5:56 am

by Tony

Lowest point is where the water settles with no applied pressure.

Re: Absolute beginner

Posted: Sun Feb 21, 2016 6:39 am

by Ravoll

Not the lowest pressure point.I mean the lowest physical point of the manometer in relation to the 10" difference.

Alan

Re: Absolute beginner

Posted: Sun Feb 21, 2016 9:09 am

by Ravoll

Or is it so?

The "0" mark, or fluid level is actually high up the inclination,and as the pressure increases the fluid level will be pushed down the inclination towards 100%?

This is what I have in my head.

I don't see it working the other way around ,simply cause there's not enough fluid in the manometer (Fig.B)

Alan