Page 3 of 17

Re: Not the Mercdog again

Posted: Wed Mar 05, 2014 6:30 pm

by Tony

Malvin wrote:

That is interesting to me

http://i144.photobucket.com/albums/r166 ... edited.jpg

http://i144.photobucket.com/albums/r166 ... edited.jpg

http://i144.photobucket.com/albums/r166 ... edited.jpg

http://i144.photobucket.com/albums/r166 ... edited.jpg

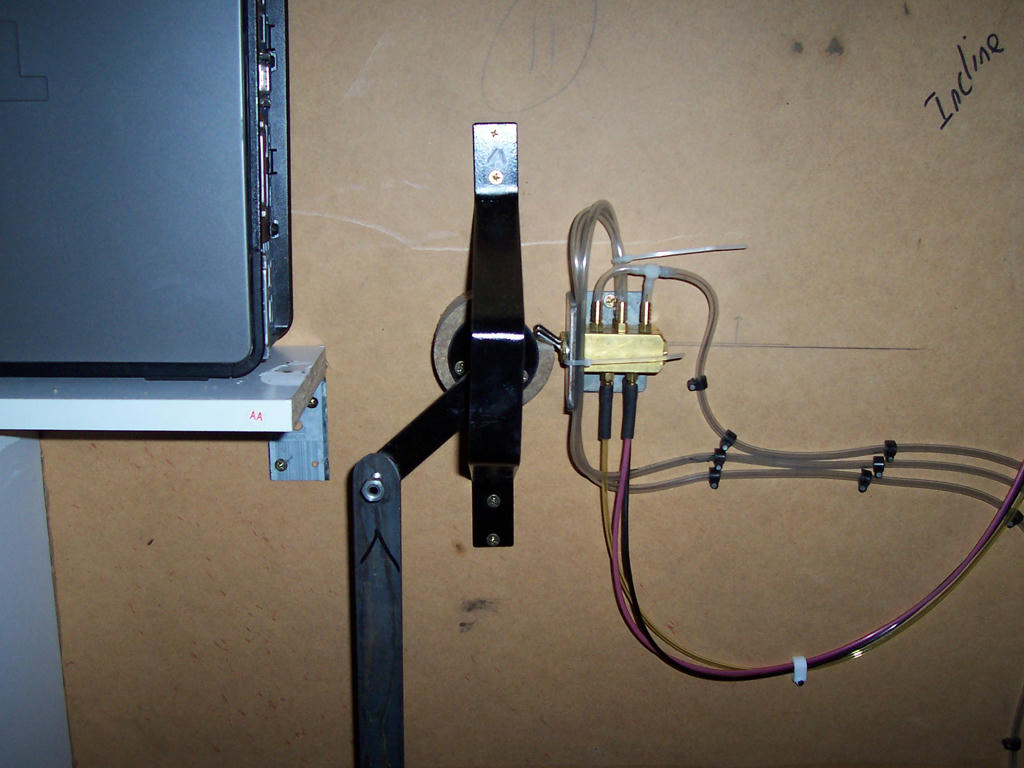

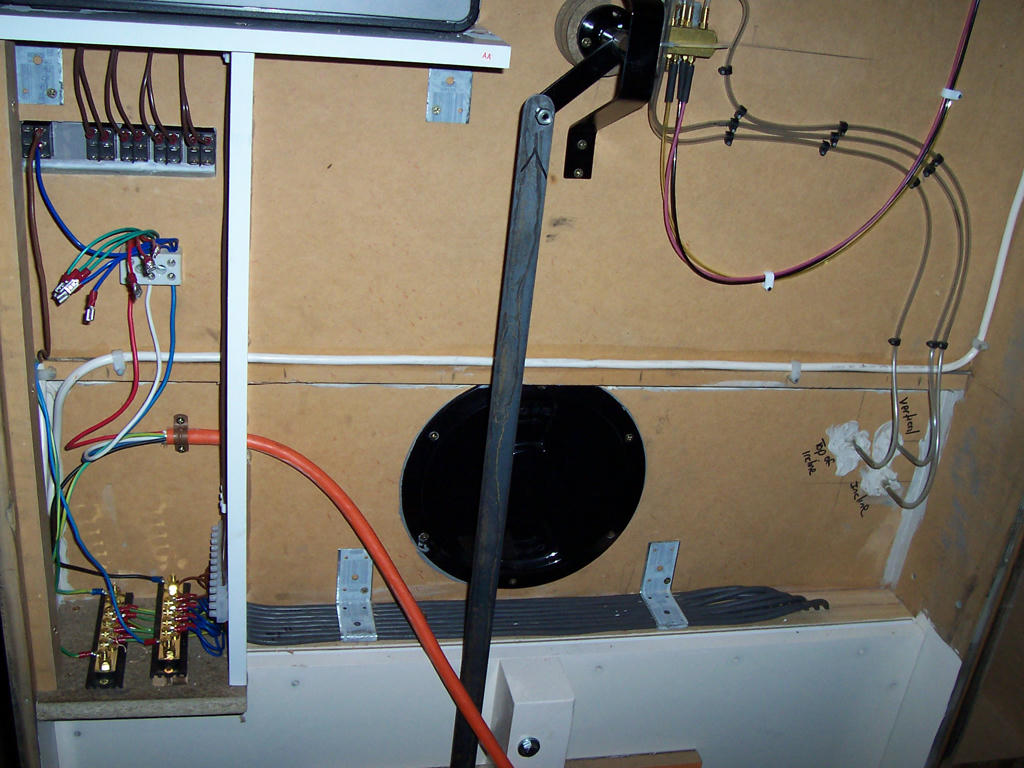

This was built a VERY long time a go.

Long before the PTS bench was ever even thought of, back when there was really nothing really good out there to copy.

Just a few of my own crazy ideas at the time, like having two test holes (one always sucks the other always blows).

Nobody else does it that way, but its a very simple way of testing without having to reverse the airflow direction within the bench which I could see no simple way of doing back then.

Re: Not the Mercdog again

Posted: Wed Mar 05, 2014 7:37 pm

by Malvin

Tony

Just a few of my own crazy ideas at the time, like having two test holes (one always sucks the other always blows).

I think its not crazy .

Looks very clean & professionally executed very nice workmanship .

Do you still use this flow bench ? Looks like its built to last .

Re: Not the Mercdog again

Posted: Wed Mar 05, 2014 7:41 pm

by Tony

Still have it, never use it these days.

Re: Not the Mercdog again

Posted: Thu Mar 06, 2014 2:40 am

by ivanhoew

gosh that's a spanky piece of kit tony ,well done .what does your present bench look like ?

Re: Not the Mercdog again

Posted: Thu Mar 06, 2014 3:28 am

by Tony

I don't really do flow testing any more, or anything much automotive.

Re: Not the Mercdog again

Posted: Thu Apr 03, 2014 4:38 pm

by Old Grey

Tony wrote:Old Grey wrote:.

The story goes that someone(Warspeed) built this Mercdog bench around Feb 2004 to Aug 2005 -

Not guilty your Worship.....

It was definitely not me, the faults were all too evident even in the very old days long before this Forum even started.

I still have a bench with a very large vertical rotating turret, but it always flows in the same direction (having two test holes).

Sealing the turret was never a problem, direct air pressure plus a big spring does that.

It also has a very large effective settling chamber ahead of the orifice, which makes a very big difference.

It has absolutely nothing in common with the original Dog design.

It initially confused me also, until I noticed the subtle difference in name - WARspeed not WARPspeed -.

Re: Not the Mercdog again

Posted: Thu Apr 03, 2014 5:56 pm

by Old Grey

Re: Not the Mercdog again

Posted: Sat Apr 05, 2014 8:38 am

by larrycavan

Why not

If it's a big blue clone you may as well make it a real one! Nice Job

I may copy that. If I do you can rest assured it's going to get a rotating orifice disk too. I have a guy with a great big lathe that can make them for me.

Re: Not the Mercdog again

Posted: Sat Apr 05, 2014 6:51 pm

by Old Grey

Larry, I was also thinking about the rotating disk, but in preliminary testing of boards at 45º angles, I found it very easy to put a bend in those boards. I checked this bench, and the 45º boards aren't flat, so it seams that pulling gaps shut and non straight cuts pre-loads the board on assembly more than 90º joints, and that means that the disk has to flex so there is no gaps under it, yet be strong enough so that it doesn't lift off if you are not sandwiching them. It's just a point to keep an eye on before you decide on which way to go, so just run a ruler on the area of the disk before you work out a solution.

My other bench is going to have a thin clamping plate that locks the disk to the o-ringed board from an external knob, for 100% seal.

Re: Not the Mercdog again

Posted: Sun Apr 06, 2014 10:21 am

by larrycavan

Old Grey wrote:Larry, I was also thinking about the rotating disk, but in preliminary testing of boards at 45º angles, I found it very easy to put a bend in those boards. I checked this bench, and the 45º boards aren't flat, so it seams that pulling gaps shut and non straight cuts pre-loads the board on assembly more than 90º joints, and that means that the disk has to flex so there is no gaps under it, yet be strong enough so that it doesn't lift off if you are not sandwiching them. It's just a point to keep an eye on before you decide on which way to go, so just run a ruler on the area of the disk before you work out a solution.

My other bench is going to have a thin clamping plate that locks the disk to the o-ringed board from an external knob, for 100% seal.

Got pics of the front side?