Page 21 of 34

Re: SF Sizes

Posted: Sun Nov 27, 2011 3:26 pm

by blaktopr

OK, cool. Now see by that test you found that your port is flowing 1.6% more than before

. What we are all trying to do here is get to the most accuracy with repeatability. Here at PTS, we are trying to get these variables into a closer "window". We can also squeeze out sharper numbers with the velocity probe. As we do this that window keeps closing.

Is that port centerline speed only? If not, to verify those FPS readings, try 9 or 11 points. Then when you are done. Try a larger and gentler radius plate for it and retest. Post your findings. Then recalibrate the bench with Bruce's plate. Get your new CFM #s. Then recheck the FPS in the method that worked the best. Do the math and see where it is. Then you will see the "window" of where the bench's sweet spot could be.

Re: SF Sizes

Posted: Sun Nov 27, 2011 4:02 pm

by Chad Speier

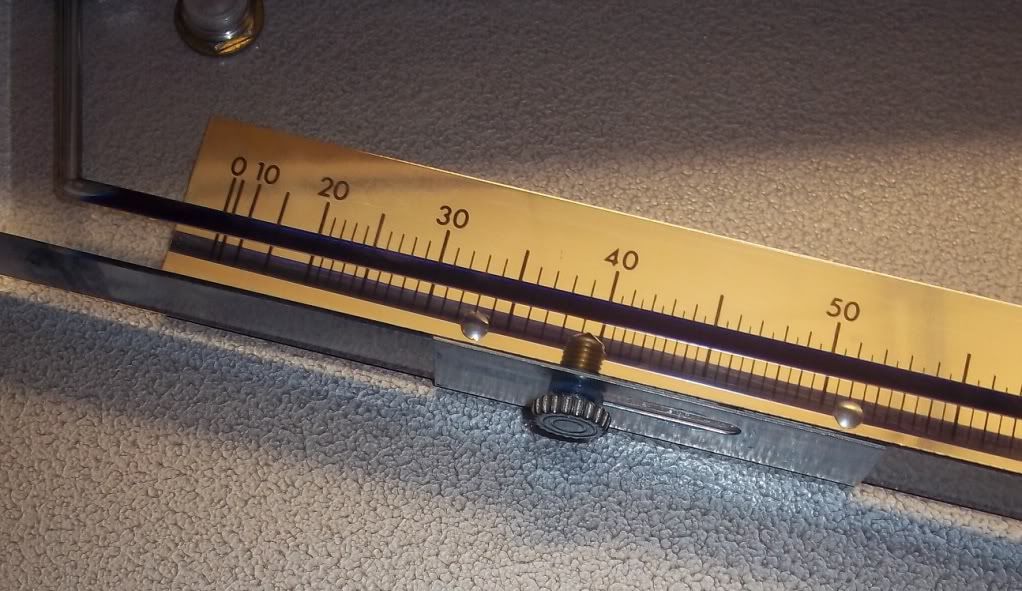

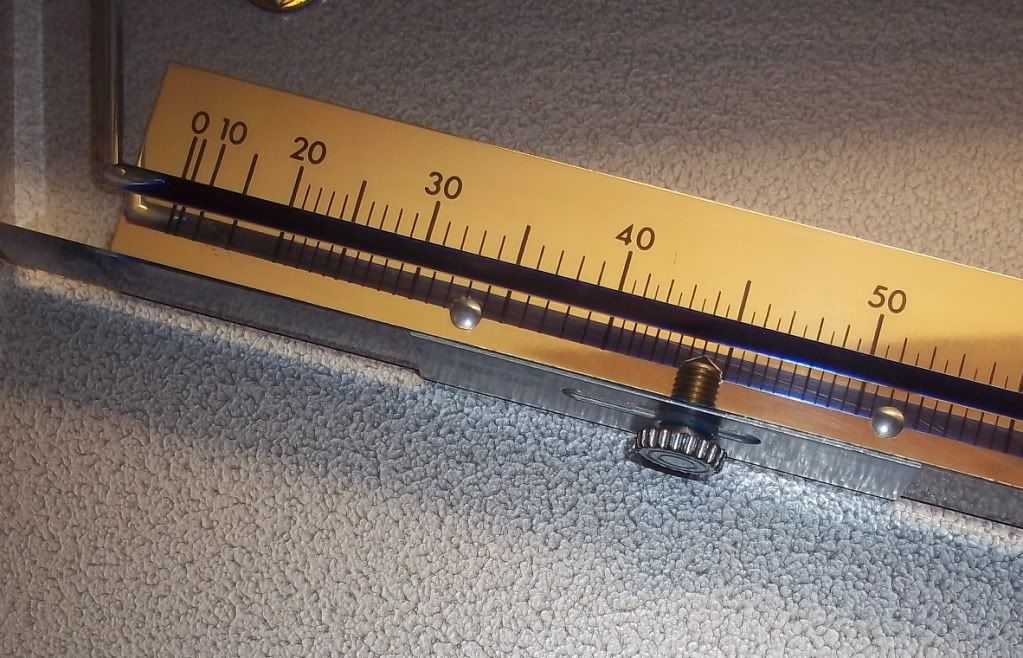

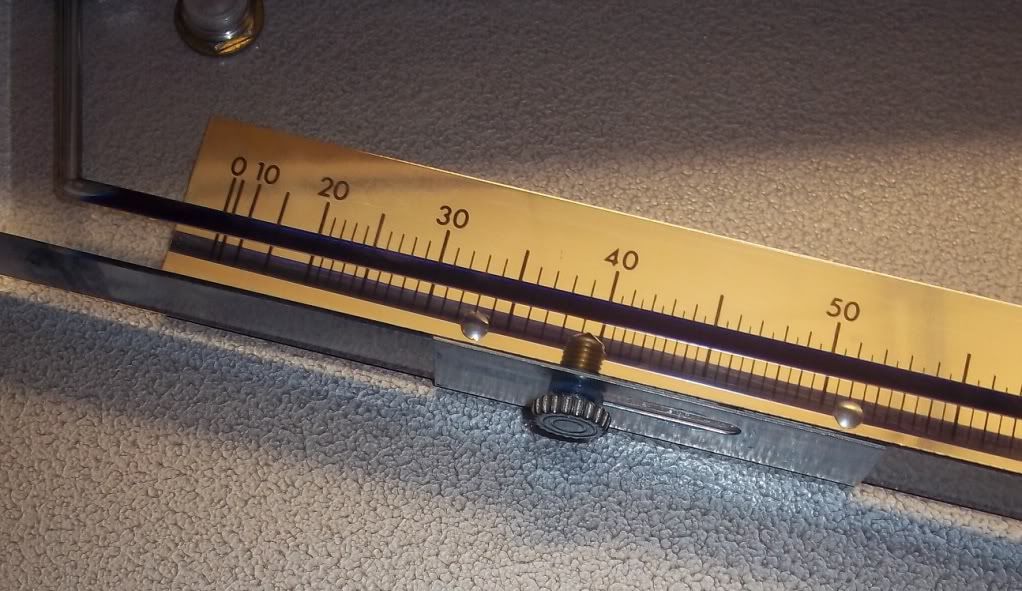

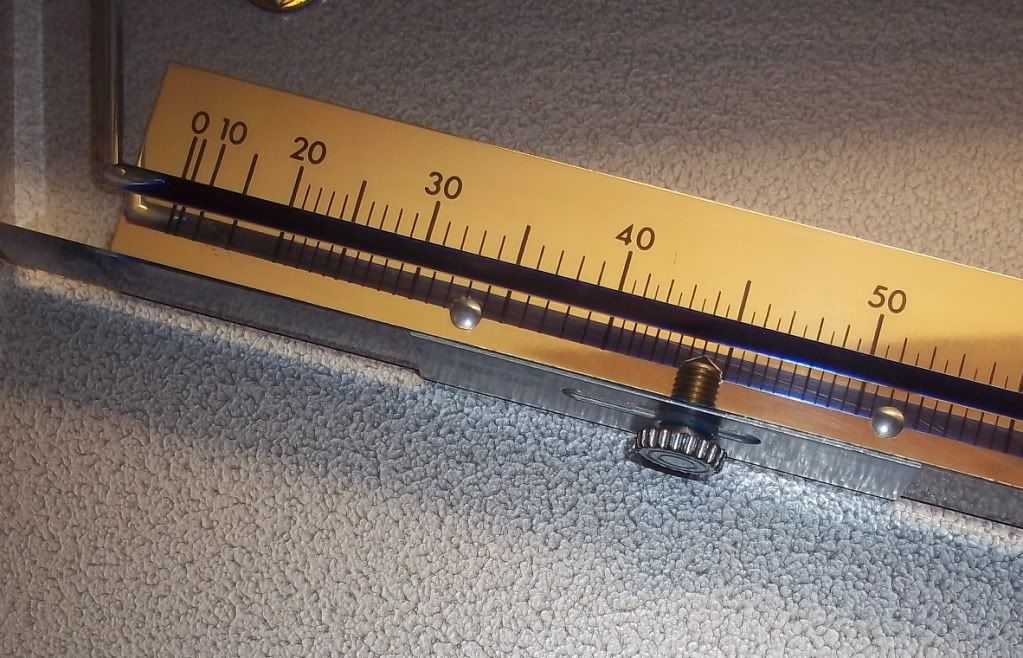

After looking at that Flowcom picture, here is something else I have a big issue with. Shouldn't these manometers be somewhat close in design and installation? Shouldn't the sliding scales be somewhat close in design and installation?

Look at these photos. If I put my scale where that one is, look at how far off it is. Now, wouldn't this effect the manometer reading??

PS. I didn't get it back to perfect zero and my battery went dead on my camera. However, it is zeroed.

Re: SF Sizes

Posted: Mon Nov 28, 2011 9:48 am

by DaveMcLain

I think your issue with the inclined is strictly caused by how much fluid is in the reservoir. I messed with this on my Superflow bench and a little bit more or less makes a BIG difference in the position of the scale. Mine was over in one direction so I added a little manometer fluid and I mean a little and it changed much more than I thought it would after the fluid had time to settle down. I think that the actual level of the fluid is arbitrary and that it won't effect the accuracy or scale of the manometer.

Re: SF Sizes

Posted: Wed Dec 07, 2011 2:19 pm

by Chad Speier

I've been using this bench for 10 days or so and here is my assumption.

In order for this bench to be correct, it needs some sort of variable cd software to fix the issue with the flow curve. It will make the curve look really good down below or up top. This is proved by what I found in comparing flow curves and calibrating the plates at high depression vs low. The cd comes in around .595-.610...

Re: SF Sizes

Posted: Wed Dec 07, 2011 9:43 pm

by 1960FL

Chad,

Mapping some sort of CD curve would take alot of research and at the end of the day be only good for that specfic orifice. If you have time PM bruce or give him a call there are some advanced ways to effect caibration in FlowSoft and this may help make your flow curve a little more linear.

Rick

Re: SF Sizes

Posted: Wed Dec 07, 2011 11:19 pm

by Chad Speier

1960FL wrote:Chad,

Mapping some sort of CD curve would take alot of research and at the end of the day be only good for that specfic orifice. If you have time PM bruce or give him a call there are some advanced ways to effect caibration in FlowSoft and this may help make your flow curve a little more linear.

Rick

I will do that!

Re: SF Sizes

Posted: Thu Dec 08, 2011 12:31 pm

by DaveMcLain

Why is the CD of the orifice changing? Is it due to some sort of geometry issue inside of the SF 600? Does it change in a similar way intake and exhaust? Is this why Superflow gave some sort of correction factor to use when testing at other than 25" of water?

Re: SF Sizes

Posted: Fri Dec 09, 2011 9:31 am

by 1960FL

Dave,

This is most likely a combination of of a few things but most likely the fact that the orifice on the disk are not machined to tolerance but laser or plasma cut and somewhat out or round (Why each bench has it own calibration). Yes one could map the CD change for his specific bench and it could be programmed around through tables but i do not think this change universal and thus could not be put into a mathematical formula for correction in software.

Rick

Re: SF Sizes

Posted: Sun Dec 18, 2011 1:28 pm

by larrycavan

I read this entire post. Very interesting. Here's what I conclude from it.

As already known, analogue gauges are subject to conditions that do not allow for ease of corrections.

eg. perfectly level manometer, condition and temperature of the gauge oil, accuracy of zero setting [to a minor degree]

I wouldn't expect any two benches to lay down identical numbers throughout a full lift cycle when testing a cylinder head, even when the same test fixture is used on both benches. Close perhaps, when using the same manometer [digital or analogue] on both benches. The reason being plenum size and shape differences.

A key factor is the influence turbulence has on the manometer probe pickup at any point during the flow test.

Anything that affects the path the air as to take on the way to the measuring point can affect the pressure at the measuring point. That is perhaps the most difficult thing to determine, much less correct. I have said for a long while and I stand by this. A large plenum with as little turbulence influence as possible will yield the most accurate measurement of a pressure differential. Ultimately that's all it comes down to. Measuring the pressure differential accurately

I don't know what the story is behind purchasing the SF600 bench but it's nice to see someone with one that will put forth the comparison effort that ultimately leads to a greater understanding of flow bench construction & design on the overall...

As it is now, there is no real, easily affordable standard to calibrate a bench with except for Bruce's plates. They've proven to be valuable in their accuracy.

JMO

Larry C

Re: SF Sizes

Posted: Mon Dec 19, 2011 6:10 pm

by DaveMcLain

Wasn't the SF 300 exactly the same as the SF 600 except for the number of blower motors and the pressure differential used across the measuring orifice? Didn't Superflow just use the same model of inclined manometer and just change from the red to the blue fluid with a higher specific gravity? Do you think this could account for some of the measuring anomalies you're seeing?

. What we are all trying to do here is get to the most accuracy with repeatability. Here at PTS, we are trying to get these variables into a closer "window". We can also squeeze out sharper numbers with the velocity probe. As we do this that window keeps closing.

. What we are all trying to do here is get to the most accuracy with repeatability. Here at PTS, we are trying to get these variables into a closer "window". We can also squeeze out sharper numbers with the velocity probe. As we do this that window keeps closing.