Grey,

I hate to ask this but have you thought about getting rid of flow control and changing it to flow directions and using motor control for depressions?

I can show you haw to average but i can't make the proverbial pig fly unless it is made by HD.

How are you extracting data from the FP1, is it going straight into the spreadsheet or is it outputting to file?

Rick

Not the Mercdog again

-

1960FL

- Posts: 1340

- Joined: Fri Jan 08, 2010 10:36 pm

- Location: Maryland

-

larrycavan

- Posts: 235

- Joined: Tue Mar 09, 2010 9:46 pm

Re: Not the Mercdog again

SF standard is +/- 1 PERCENT...NOT 1CFM.

Yes...a leak in the tubing would be a bastard to find and could drive you nuts for a while...good catch!

I just read one of the links to your averaging questions and the replies. I noticed that you're having issues with the flow control valves as well. You added ball bearings???

There was a very simple cure for that problem. A bead of silicone on the valve sealing surface and spray the valve with silicone spray. Close the valve, let it sit overnight while the silicone sealer dries.....crank the valve open the next day. Mine's been like that since 1994. Works perfectly..... KISS is always the best approach

I don't know how much head porting you do but realize this. Most generally you'll find that you get the head flowing more than the calculated requirements are for the engine it's going to get bolted to. There's the small matter of actually getting the engine to use all the available flow it has at it's disposal....That's where the Ve number comes from when you calculate potential power. Then comes the matter of the dyno and your discover that what is available vs what is actually being used are two different things. It's at about that time you realize that chasing CFM is indeed a wild goose chase. That's precisely why so many pros don't rank CFM as highest on the list of important things to look at when flow testing.....

Get the thing repeating. If it reads a few CFM different than someone elses bench...DO NOT WORRY ABOUT IT...

A good number of years ago I was talking to a guy that was racing a GS1100 Suzuki. They had a head that flowed 99CFM @10". They also had a head that flowed 120CFM at 10". The extra 20CFM that the other head flowed was impressive to the flowbench. The Suzuki motor didn't give a rats ass about it though..... it didn't go any quicker...

Yes...a leak in the tubing would be a bastard to find and could drive you nuts for a while...good catch!

I just read one of the links to your averaging questions and the replies. I noticed that you're having issues with the flow control valves as well. You added ball bearings???

There was a very simple cure for that problem. A bead of silicone on the valve sealing surface and spray the valve with silicone spray. Close the valve, let it sit overnight while the silicone sealer dries.....crank the valve open the next day. Mine's been like that since 1994. Works perfectly..... KISS is always the best approach

I don't know how much head porting you do but realize this. Most generally you'll find that you get the head flowing more than the calculated requirements are for the engine it's going to get bolted to. There's the small matter of actually getting the engine to use all the available flow it has at it's disposal....That's where the Ve number comes from when you calculate potential power. Then comes the matter of the dyno and your discover that what is available vs what is actually being used are two different things. It's at about that time you realize that chasing CFM is indeed a wild goose chase. That's precisely why so many pros don't rank CFM as highest on the list of important things to look at when flow testing.....

Get the thing repeating. If it reads a few CFM different than someone elses bench...DO NOT WORRY ABOUT IT...

A good number of years ago I was talking to a guy that was racing a GS1100 Suzuki. They had a head that flowed 99CFM @10". They also had a head that flowed 120CFM at 10". The extra 20CFM that the other head flowed was impressive to the flowbench. The Suzuki motor didn't give a rats ass about it though..... it didn't go any quicker...

Larry C

http://www.cavanaughracing.com

http://www.cavanaughracing.com

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

There is very little wrong with the flow control valve at the moment - I would say it's 90% of a SF -, it's just that I opened my mouth and described a SF valve to the guy, and now he wants one like it.

Actually 50% of the control valve problems was mechanical. Stop bowl bottom flex, making the bowl rotate interdependently of the screw so it didn't grab the rubber seal and still be ridged enough that it didn't rattle. In my opinion a longer screw with a support bracket on the free end would make it perfect.

The other 50% was not setting up the FP1 properly. Trying to set depression at low lifts with the FP1 set on slow sampling and only digital numbers, was nearly impossible. Switching it to fast sampling and a graphical manometer made it a joy to control.

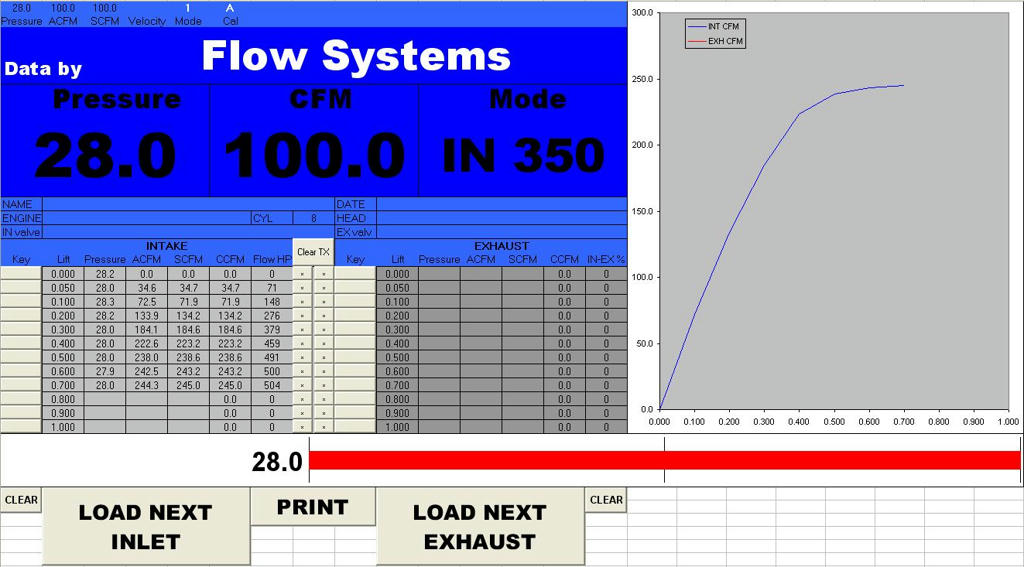

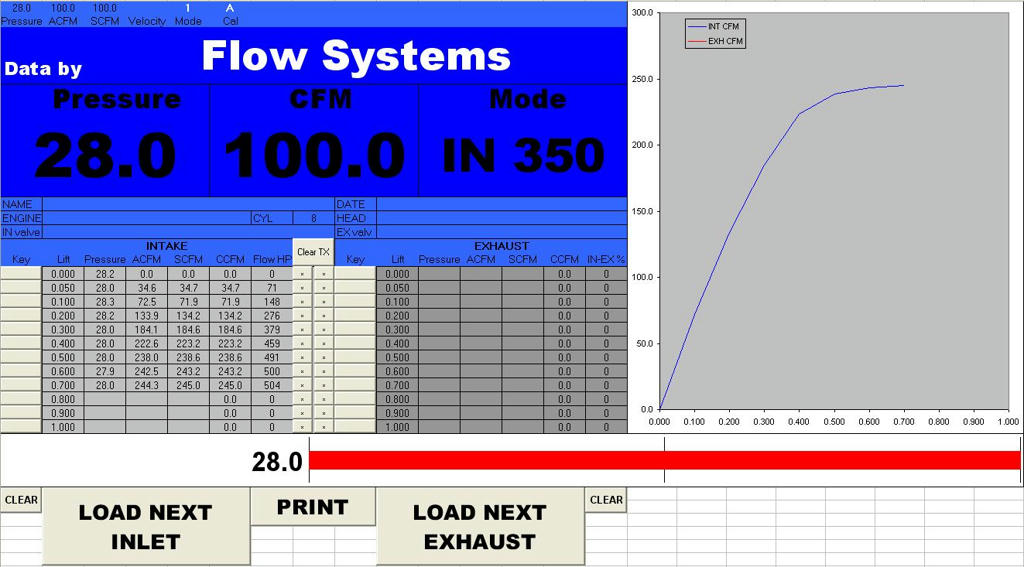

The spread sheet is the standard sheet, but made fancy and faster. All the buttons do is simply paste the inputs from the FP1 at A1 - C1, to places on the table.

Thanks Larry, so it's actually 1%.

I do know about flow demand over supply. I took me 2 years to read every Speedtalk post from the beginning, to 2007 - I have 7000 pages printed out as references, and that just the stuff that interested me -, and I learned about demand and velocity. Everything that we touch now follows those guidelines, and on average everything we touch makes about 20% more power than we ever did before. Actually the 2nd head I ported I miss calculated the flow I needed, and when I asked Larry Meaux why a head(2L 4cyl) that flows 350hp only made 260hp, he set me straight.

Actually 50% of the control valve problems was mechanical. Stop bowl bottom flex, making the bowl rotate interdependently of the screw so it didn't grab the rubber seal and still be ridged enough that it didn't rattle. In my opinion a longer screw with a support bracket on the free end would make it perfect.

The other 50% was not setting up the FP1 properly. Trying to set depression at low lifts with the FP1 set on slow sampling and only digital numbers, was nearly impossible. Switching it to fast sampling and a graphical manometer made it a joy to control.

The spread sheet is the standard sheet, but made fancy and faster. All the buttons do is simply paste the inputs from the FP1 at A1 - C1, to places on the table.

Thanks Larry, so it's actually 1%.

I do know about flow demand over supply. I took me 2 years to read every Speedtalk post from the beginning, to 2007 - I have 7000 pages printed out as references, and that just the stuff that interested me -, and I learned about demand and velocity. Everything that we touch now follows those guidelines, and on average everything we touch makes about 20% more power than we ever did before. Actually the 2nd head I ported I miss calculated the flow I needed, and when I asked Larry Meaux why a head(2L 4cyl) that flows 350hp only made 260hp, he set me straight.

-

larrycavan

- Posts: 235

- Joined: Tue Mar 09, 2010 9:46 pm

Re: Not the Mercdog again

A couple incidentals that might be useful as you tweak things to your liking.

The orifice depression probes work best when they're in a quiet area of the chamber. PTS uses flush mount probes to the best of my knowledge but I used tubing that extends away from the walls a couple of inches. I can't say one is better than the other. I just happened to have done mine that way and left it at that when I modified the bench.

The test pressure sensor sensor location seems very comfortable just about anywhere you place it so long as it's not in the test cylinder. You can stick a piece of hose on the connection to extend the reach and move it to various locations in the top chamber. Initially, in 94 I had that probe in the cylinder per design spec. I could move it in or out and change the depression reading. Definitely NOT the hot setup. Mine now sits at a right angle to to and on top of the baffle I installed in the top chamber.

I understand the desire to press hard for accuracy for your customer. You're never going to be accused of not paying attention to details...that's for sure

When the time comes, I will contact you for your address and send you a beta of something brand new.

The orifice depression probes work best when they're in a quiet area of the chamber. PTS uses flush mount probes to the best of my knowledge but I used tubing that extends away from the walls a couple of inches. I can't say one is better than the other. I just happened to have done mine that way and left it at that when I modified the bench.

The test pressure sensor sensor location seems very comfortable just about anywhere you place it so long as it's not in the test cylinder. You can stick a piece of hose on the connection to extend the reach and move it to various locations in the top chamber. Initially, in 94 I had that probe in the cylinder per design spec. I could move it in or out and change the depression reading. Definitely NOT the hot setup. Mine now sits at a right angle to to and on top of the baffle I installed in the top chamber.

I understand the desire to press hard for accuracy for your customer. You're never going to be accused of not paying attention to details...that's for sure

When the time comes, I will contact you for your address and send you a beta of something brand new.

Larry C

http://www.cavanaughracing.com

http://www.cavanaughracing.com

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

I did 1 day of moving the pick-ups around - ½ a day moving them, and ½ a day moving them back again -.

The upper chamber pick-ups have a 0.040" restrictors on the end, are in small a housing, and are located under the baffle board at the back - I think this is the quietest area -.

The lower one was where I had the problem, hence the ½ day putting things back. I had the pick-up in the centre near the port hole, but when I looked inside I saw dirt accumulating at the front corners. Assuming this was a stagnant point where dirt drops out of suspension I put the pick-up there. Unfortunately all the reading now read 10 cfm higher. I tried re calibration, but it had thrown the whole bench out, so I had to pull it out and test other areas. It seams that the only bad area is the front corners where the dirt settles. The pick-up is now floating in mid area on the end of the brass tube of the bench.

Larry you have already sent me an old version of your program - because of my meagre resources - for my old FP1. I'm using Excel 97 and XP-32.

The upper chamber pick-ups have a 0.040" restrictors on the end, are in small a housing, and are located under the baffle board at the back - I think this is the quietest area -.

The lower one was where I had the problem, hence the ½ day putting things back. I had the pick-up in the centre near the port hole, but when I looked inside I saw dirt accumulating at the front corners. Assuming this was a stagnant point where dirt drops out of suspension I put the pick-up there. Unfortunately all the reading now read 10 cfm higher. I tried re calibration, but it had thrown the whole bench out, so I had to pull it out and test other areas. It seams that the only bad area is the front corners where the dirt settles. The pick-up is now floating in mid area on the end of the brass tube of the bench.

Larry you have already sent me an old version of your program - because of my meagre resources - for my old FP1. I'm using Excel 97 and XP-32.

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

Actually, I meant that that was my 2nd serious head. I have been porting since the late 70's, and had put quite a few car to the front of the field, it's just that after reading about how the pros were doing it, I realised I didn't know anything pre 2005.Old Grey wrote:Actually the 2nd head I ported I miss calculated the flow I needed, and when I asked Larry Meaux why a head(2L 4cyl) that flows 350hp only made 260hp, he set me straight.

-

larrycavan

- Posts: 235

- Joined: Tue Mar 09, 2010 9:46 pm

Re: Not the Mercdog again

I hear you. Speedtalk was a hotbed of excellent discussions back then. Larry Meaux and Darin Morgan shared priceless information. I don't know if they realize just how much they contributed to everyone's knowledge. Awesome guys!

Larry C

http://www.cavanaughracing.com

http://www.cavanaughracing.com

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

I lived on the forum from 2004 to 2007, and are great-full they shared because there was no way I could have afforded to find out what they told us working in a such small shop, but right now I feel like I'm stuck in 2007 because I haven't learnt any thing new since then - this is what I'm building the POS bench for -.

I would love to know what you know Larry because you work in the upper end of engine design - m/cylce engines are in that area of very high hp/cube -, so you must be seeing things similar to what Prostock engine builders see - you will have to tell me what sustainable velocity's you are using one day -.

I would love to know what you know Larry because you work in the upper end of engine design - m/cylce engines are in that area of very high hp/cube -, so you must be seeing things similar to what Prostock engine builders see - you will have to tell me what sustainable velocity's you are using one day -.

-

larrycavan

- Posts: 235

- Joined: Tue Mar 09, 2010 9:46 pm

Re: Not the Mercdog again

Velocity...average velocity....I get good results with 280 FPS. On hemi heads, bowl volume is your friend. Throat size depends on how the motor is going to be used. Don't lay the short side back any further than you have to and if you get the flow you need without laying it back the don't get greedy and go for more by laying it back. It's hard to describe but I like to move it back rather than laying it back, then shape the top edge of the floor where it starts the turn down....Old Grey wrote:I lived on the forum from 2004 to 2007, and are great-full they shared because there was no way I could have afforded to find out what they told us working in a such small shop, but right now I feel like I'm stuck in 2007 because I haven't learnt any thing new since then - this is what I'm building the POS bench for -.

I would love to know what you know Larry because you work in the upper end of engine design - m/cylce engines are in that area of very high hp/cube -, so you must be seeing things similar to what Prostock engine builders see - you will have to tell me what sustainable velocity's you are using one day -.

And I would love to know what those guys forgot

Here's some of my recent work..if this link works that is... https://www.facebook.com/cavanaughracingheads?ref=hl

Honestly, I love working on the older bikes more because the new heads are so good that is hard to take them to the level of performance that you can with an old one. The older bikes really respond to porting and even drop in cams.

Larry C

http://www.cavanaughracing.com

http://www.cavanaughracing.com

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

I think I know what you mean. Keep the short side radiused, just start it earlier up the runner.

Darin said the Prostock runs at 325ft/sec, but Larry said he always find more torque at 250-280ft/sec. I was under the impression that the straighter the port the higher velocity sweet spot would be, ie F1 ports would make the most hp and tq at 350ft/sec because they are so straight. Maybe in Prostock drops TQ for hp.

I know what you mean about modern stuff, that 2.0L multi valve was the hardest I had to work to get an improvement - there was more in the seats and valves than the actual port -. We used to service 355 Ferrari heads, and when the boss's friend brought his in, the boss wanted me to port them. I took one look at those late model 5 valves heads and nearly died, because I couldn't see one area that would make a difference if I touched it.

Darin said the Prostock runs at 325ft/sec, but Larry said he always find more torque at 250-280ft/sec. I was under the impression that the straighter the port the higher velocity sweet spot would be, ie F1 ports would make the most hp and tq at 350ft/sec because they are so straight. Maybe in Prostock drops TQ for hp.

I know what you mean about modern stuff, that 2.0L multi valve was the hardest I had to work to get an improvement - there was more in the seats and valves than the actual port -. We used to service 355 Ferrari heads, and when the boss's friend brought his in, the boss wanted me to port them. I took one look at those late model 5 valves heads and nearly died, because I couldn't see one area that would make a difference if I touched it.