I built a bench roughly following this design last year:

http://www.dtec.net.au/Flowbench%20Design%20Guide.htm

I've never been happy with it, and wanted to build a new one over this summer, still using water manometers.

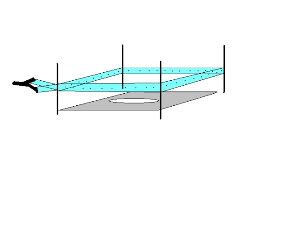

I've seen (on here) a design which uses a table over the top of the orifice plate, which I will employ in my new bench.

Question is; where should I be mounting my pressure tapping's?

In the old bench they look like this.

I'm not convinced that this is accurate.

I was thinking of using tubing like an annubar, and wrapping it around the legs of the table in a circle.

Thoughts?

Any pictures of your set ups would be cool.

Varnish