calibrated orifice plate ?? - orifice plate

37 posts

• Page 2 of 3 • 1, 2, 3

Flow thru the orifices should still match the calibration at a given test pressure point.

I found that on one of our Blue Benches that is

running at 208 3 phase vs the normal 220 2 phase, (we use a converter box) the max air flow is down but the bench still reads the calibrated

air flow when tested at the blue bench orifice calibration pressure of 25" of water.

Tom V.

I found that on one of our Blue Benches that is

running at 208 3 phase vs the normal 220 2 phase, (we use a converter box) the max air flow is down but the bench still reads the calibrated

air flow when tested at the blue bench orifice calibration pressure of 25" of water.

Tom V.

- ThomasVaught

- Posts: 80

- Joined: Fri Jul 06, 2007 9:06 pm

I didn't think the line voltage would effect the calibration, ..

but it does effect the max the bench will pull, .. killed 100 cfm !

I can get a transformer for a few hundred bucks to bring it back up, .

The calibration issue, .. The peole who import it and make it

are 1,000% behind getting to the bottom of the issue, ..

good people so during this thread I don't want anyone to get the wrong

idea.

That said, .. they are looking into it right now and will get back to me, ..

I may try to find out the orifice sizes in the bench and maybe do my

own calibration.

it's a copy of a SF-600 only built a little better.

any ideas on calibrating this thing?, ..

can I just use my orifice plates to estimate the ranges, .. ?

say if my 400 cfm plate flows 67% I can calc out the max of that range?

See, . I should have worked harder on math while in school. :p

Curtis

but it does effect the max the bench will pull, .. killed 100 cfm !

I can get a transformer for a few hundred bucks to bring it back up, .

The calibration issue, .. The peole who import it and make it

are 1,000% behind getting to the bottom of the issue, ..

good people so during this thread I don't want anyone to get the wrong

idea.

That said, .. they are looking into it right now and will get back to me, ..

I may try to find out the orifice sizes in the bench and maybe do my

own calibration.

it's a copy of a SF-600 only built a little better.

any ideas on calibrating this thing?, ..

can I just use my orifice plates to estimate the ranges, .. ?

say if my 400 cfm plate flows 67% I can calc out the max of that range?

See, . I should have worked harder on math while in school. :p

Curtis

Curtis Boggs

Racing Flow Development.

Racing Flow Development.

- cboggs

- Posts: 118

- Joined: Sun Mar 06, 2005 12:39 pm

- Location: Lorton, VA

Let me add this . . . if anyone gets plates from me in 100, 200 and 300cfm I flow them against the pass-around-plates ie I flow the pass-around-plate and then flow your plate this gives me a +/- number which is then written on your plate. This lets you know how your plate flowed in relation to the pass-around-plates.

"There is no more formidable adversary than one who perceives he has nothing to lose." - Gen. George S. Patton

- bruce

- Site Admin

- Posts: 1638

- Joined: Sun May 09, 2004 12:17 pm

My plates have been flowed on a few other benches, .. main

one is a local SF-600 that I know hase been very well calibrated.

OK, .. asking a few more questions, ..

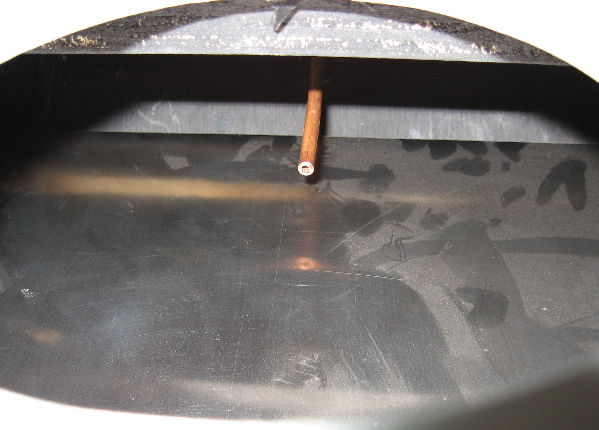

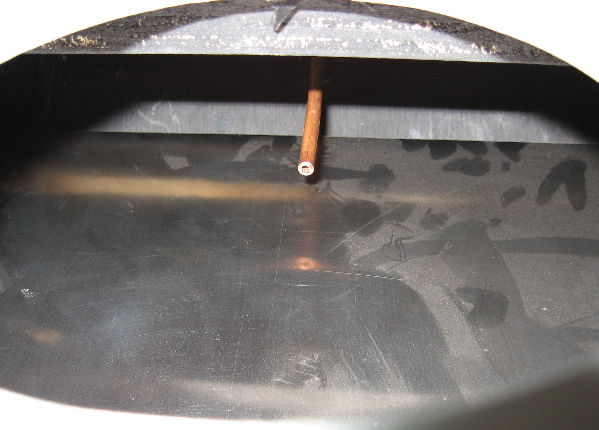

The pressure pick up tube that is just under the adaptor opening, ..

it would be just under the head adaptor and above the diffuser plate, ..

if that was too close to the opening, could that scew the readings at

higher flow rates?

Say if my 160 cfm plate flows dead on in the 616cfm range, ..

but the 400 cfm plate reads 435 cfm ??

How far back should this pick up be ?

I do have electronics on the bench, and there is a very little manometer

bounce, . . I took the electronics out and no changes.

The people who I bought this flow bench from are top notch, . .

not only are they helping to work through this but seem excited

about making their product better, .. good people.

They e-mailed me the orifice disc openings so I can check the CD

myself, . I'll have to find the spread sheet.

The voltage issue and capacity loss can be resolved by a transformer, ..

not very expensive, .. Grainger has them.

Curtis

one is a local SF-600 that I know hase been very well calibrated.

OK, .. asking a few more questions, ..

The pressure pick up tube that is just under the adaptor opening, ..

it would be just under the head adaptor and above the diffuser plate, ..

if that was too close to the opening, could that scew the readings at

higher flow rates?

Say if my 160 cfm plate flows dead on in the 616cfm range, ..

but the 400 cfm plate reads 435 cfm ??

How far back should this pick up be ?

I do have electronics on the bench, and there is a very little manometer

bounce, . . I took the electronics out and no changes.

The people who I bought this flow bench from are top notch, . .

not only are they helping to work through this but seem excited

about making their product better, .. good people.

They e-mailed me the orifice disc openings so I can check the CD

myself, . I'll have to find the spread sheet.

The voltage issue and capacity loss can be resolved by a transformer, ..

not very expensive, .. Grainger has them.

Curtis

Curtis Boggs

Racing Flow Development.

Racing Flow Development.

- cboggs

- Posts: 118

- Joined: Sun Mar 06, 2005 12:39 pm

- Location: Lorton, VA

Larry is right on the money on the test pressure pick-up information.

The "Velocity Shield" around my pick-up is 1.50" long and 1/2" in diameter with the "shield" tube end plugged and the inner tube located

at the center point of the larger "shield tube". It hangs in space inside the shield tube. A series of 5 small .040 holes in a row at three locations on the tube 12:00, 4:00, and at 8:00 (15 holes total) are drilled into the outer tube. My test pressure tube has a 1/4" od. No issues at all from

the currents inside the bench.

A second thought is that the pick-up tube might be influenced by the

flow off the baffle if it is near it. Move the pick-up tube not the baffle.

One last comment about electronic manometers. On the Ford bench

we wait for at least 20 seconds before taking a reading. We actually

have a "sweep meter" on the bench to read the oscillations prior to the

bench test pressure calming down. The meter looks like a 90 degree

sweep normal meter with Zero in the top center of the gauge. When the

oscillations have calmed down to where the needle is near the "0" point

we "trap" the reading.

Tom V.

The "Velocity Shield" around my pick-up is 1.50" long and 1/2" in diameter with the "shield" tube end plugged and the inner tube located

at the center point of the larger "shield tube". It hangs in space inside the shield tube. A series of 5 small .040 holes in a row at three locations on the tube 12:00, 4:00, and at 8:00 (15 holes total) are drilled into the outer tube. My test pressure tube has a 1/4" od. No issues at all from

the currents inside the bench.

A second thought is that the pick-up tube might be influenced by the

flow off the baffle if it is near it. Move the pick-up tube not the baffle.

One last comment about electronic manometers. On the Ford bench

we wait for at least 20 seconds before taking a reading. We actually

have a "sweep meter" on the bench to read the oscillations prior to the

bench test pressure calming down. The meter looks like a 90 degree

sweep normal meter with Zero in the top center of the gauge. When the

oscillations have calmed down to where the needle is near the "0" point

we "trap" the reading.

Tom V.

- ThomasVaught

- Posts: 80

- Joined: Fri Jul 06, 2007 9:06 pm

Thanks guys, .

I'm heading to the shop, .. I'll get a photo of the pressure pick up

that is right below the test hole, ..

I'm also going to put a plastic hose on the end a relocate the

pick up and see what that does, .

where is this pick up located in the big blue bench ?

Curtis

I'm heading to the shop, .. I'll get a photo of the pressure pick up

that is right below the test hole, ..

I'm also going to put a plastic hose on the end a relocate the

pick up and see what that does, .

where is this pick up located in the big blue bench ?

Curtis

Curtis Boggs

Racing Flow Development.

Racing Flow Development.

- cboggs

- Posts: 118

- Joined: Sun Mar 06, 2005 12:39 pm

- Location: Lorton, VA

It has been a while Curtis but I believe, when looking at the bench from

the front, up in the left hand corner.

All of the blow bench plumbing for the manometers is on the right side when looking from the back. Flow Com plumbing comes thru the bench

on that side too.

Hope that helps, Curtis.

Tom V.

the front, up in the left hand corner.

All of the blow bench plumbing for the manometers is on the right side when looking from the back. Flow Com plumbing comes thru the bench

on that side too.

Hope that helps, Curtis.

Tom V.

- ThomasVaught

- Posts: 80

- Joined: Fri Jul 06, 2007 9:06 pm

OK, .. getting some where, . I moved the pick up and it really had an effect.

The top chamber on the bench is very small / tight and it does have

some influence on the pressure pick up. I moved it and dropped my test from

428cfm on the plate to 416 cfm, .. a big jump.

here's what it looks like stock.

problem is, .. whithout taking the bench appart I can't really reach into

the chamber to try and find a quiet corner, .. and it's so tight in there

I doubt there really is one.

I tried a "diffuser" on the end, .. a piece of tubing to move it to

attached to the top plate just beside the test hole, .. the quietest

place but it was still not right.

I also tried blocking the flow across the rear of the diffuser plate behind

the pick up, so the flow went to the sides of the diffuser, .. didn't change.

Anyone have any ideas?

Tom, .. is the Blue bench that small or tight inside?

Do you think if I could get in there, .. moving the pressure pick up

to a back corner would fix it?\

I thought the pressure pick ups where supposed to be close to the orifice

you're measuring.

This does explain why the lower volume readings where fairly close

but as the volume of the readings, .. 540 cfm heads, .. went up

so did the inaccuracy.

Curtis

The top chamber on the bench is very small / tight and it does have

some influence on the pressure pick up. I moved it and dropped my test from

428cfm on the plate to 416 cfm, .. a big jump.

here's what it looks like stock.

problem is, .. whithout taking the bench appart I can't really reach into

the chamber to try and find a quiet corner, .. and it's so tight in there

I doubt there really is one.

I tried a "diffuser" on the end, .. a piece of tubing to move it to

attached to the top plate just beside the test hole, .. the quietest

place but it was still not right.

I also tried blocking the flow across the rear of the diffuser plate behind

the pick up, so the flow went to the sides of the diffuser, .. didn't change.

Anyone have any ideas?

Tom, .. is the Blue bench that small or tight inside?

Do you think if I could get in there, .. moving the pressure pick up

to a back corner would fix it?\

I thought the pressure pick ups where supposed to be close to the orifice

you're measuring.

This does explain why the lower volume readings where fairly close

but as the volume of the readings, .. 540 cfm heads, .. went up

so did the inaccuracy.

Curtis

Curtis Boggs

Racing Flow Development.

Racing Flow Development.

- cboggs

- Posts: 118

- Joined: Sun Mar 06, 2005 12:39 pm

- Location: Lorton, VA

More photos of the bench would be helpful.

An easy way to get the pickup into the back rear corner of the bench would be to use a piece of brake line and connect it to your current pickup with hose. I'd add the radially drilled holes to that as well.

I'd bend the line so the end is up off the surface of the wall it's attached to and secure it with a simple clamp and screw somewhere near the intake hole so you can reach it easily.

I've seen other benches with the pickup located right next to the flow disk orifice.

FWIW - What's being measured is 2 pressure differentials.

One between the atmosphere and the top chamber [test pressure]

The other between the top and bottom chambers [differential pressure from which, flow calculations are derived]

In either measurement, I personally think it's wise to have the pickups located in calm areas so they are not easily affected by velocity pressure.

NOTE: The test pressure and the top plenum pressure should yield the same reading. Even though they are connected to 2 different guages, they should sense the same pressure reading.

Often, the test pressure and top plenum pressure pickups are two separate components of the bench. There is nothing wrong with that design BUT what can happen under dynamic operating conditions is that one pickup becomes influenced by velocity pressure while the other doesn't. Things get funky when that happens.

At 10" of test pressure, perhaps the environment in the chamber is such that both pickups function in unison with each other. Then at some point along the way, as test pressure is increased, dynamic flow conditions begin to disrupt the uniformity and begin to ram velocity pressure into one of the probes.

Depending on the size / shape of the plenum, baffle and pickup locations, the approach to achieving uniform pressure sensing can be different for different benches.

It's very possible that a simple piece of foam, with the right core cell size, slipped over the end of the pickup could cure the problem.

Tom's shielded setup sounds pretty good to me. It would be pretty easy to fabricate and slip right over your current pickup or the relocated brake line pickup I suggested at the beginning of this post.

One thing about this situation kind of ticks me off. The manufacturer of the bench will end up getting "free" support that can / will improve their product, for which they receive $$$$$$$.

Then again, maybe that's par for the course and "payback" for all the design concepts that have been copied freely over the years.

Does your bench had the raised top section like the one in the photo?

An easy way to get the pickup into the back rear corner of the bench would be to use a piece of brake line and connect it to your current pickup with hose. I'd add the radially drilled holes to that as well.

I'd bend the line so the end is up off the surface of the wall it's attached to and secure it with a simple clamp and screw somewhere near the intake hole so you can reach it easily.

I've seen other benches with the pickup located right next to the flow disk orifice.

FWIW - What's being measured is 2 pressure differentials.

One between the atmosphere and the top chamber [test pressure]

The other between the top and bottom chambers [differential pressure from which, flow calculations are derived]

In either measurement, I personally think it's wise to have the pickups located in calm areas so they are not easily affected by velocity pressure.

NOTE: The test pressure and the top plenum pressure should yield the same reading. Even though they are connected to 2 different guages, they should sense the same pressure reading.

Often, the test pressure and top plenum pressure pickups are two separate components of the bench. There is nothing wrong with that design BUT what can happen under dynamic operating conditions is that one pickup becomes influenced by velocity pressure while the other doesn't. Things get funky when that happens.

At 10" of test pressure, perhaps the environment in the chamber is such that both pickups function in unison with each other. Then at some point along the way, as test pressure is increased, dynamic flow conditions begin to disrupt the uniformity and begin to ram velocity pressure into one of the probes.

Depending on the size / shape of the plenum, baffle and pickup locations, the approach to achieving uniform pressure sensing can be different for different benches.

It's very possible that a simple piece of foam, with the right core cell size, slipped over the end of the pickup could cure the problem.

Tom's shielded setup sounds pretty good to me. It would be pretty easy to fabricate and slip right over your current pickup or the relocated brake line pickup I suggested at the beginning of this post.

One thing about this situation kind of ticks me off. The manufacturer of the bench will end up getting "free" support that can / will improve their product, for which they receive $$$$$$$.

Then again, maybe that's par for the course and "payback" for all the design concepts that have been copied freely over the years.

Does your bench had the raised top section like the one in the photo?

- larrycavan

- Site Admin

- Posts: 1183

- Joined: Fri Apr 01, 2005 4:40 pm

37 posts

• Page 2 of 3 • 1, 2, 3

Who is online

Users browsing this forum: No registered users and 3 guests