Hello everyone,

I have been lurking around here for a few days reading what everyone has done to date and I must say this forum and your succeses are a credit to all involved. This information has saved me at least two bench redesigns.

I am embarking on my own flow bench build so that I can investigate a YB Cosworth cylinder head from an English Ford.

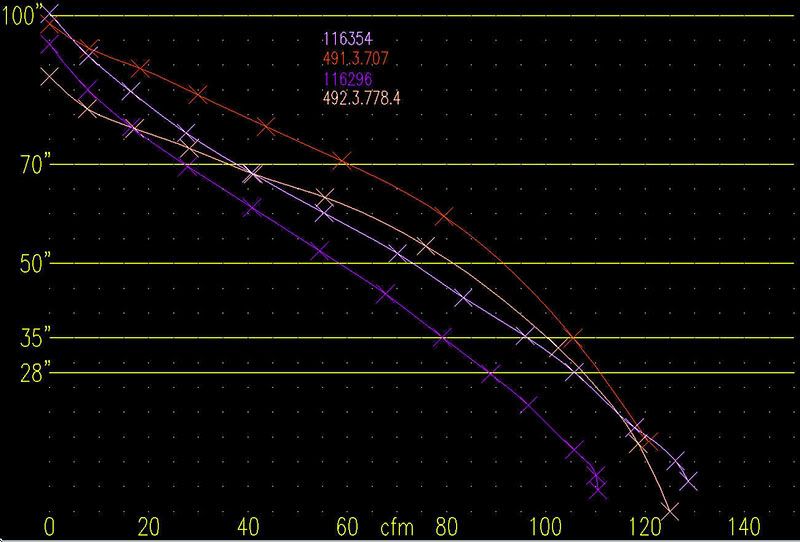

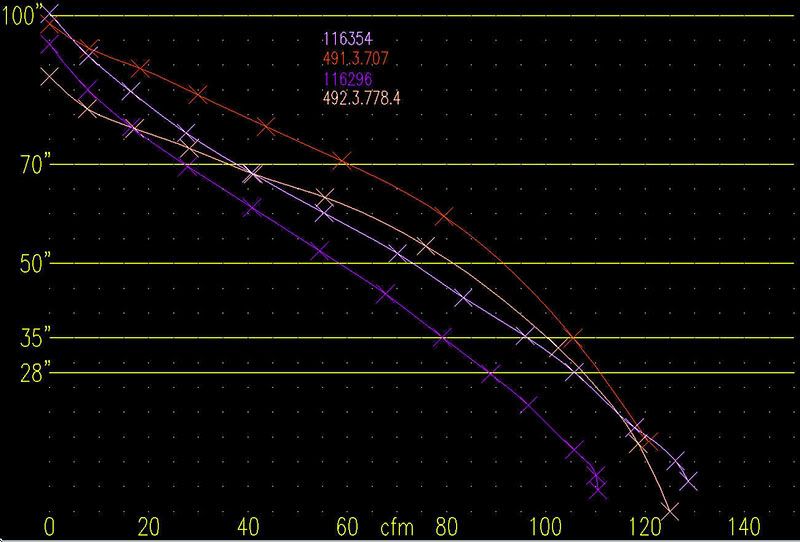

I have lashed out and bought 12 of the 491.3.707 motors with flow specs as per the attached chart.

Initially I had thoughts of Laminar Flow Elements or a Thermal Mass Flow Transducer for measuring flow, but it seems orifi and pitot's can be set up in a bench to work accurately. Always thought it odd to use measuring devices that were affected by the turbulence that should be generated by port flow.

I see orifi are commonly setup to use 6" or 13" max pressure loss for measuring flow. What about Pitot's, often stated as 2" insertion loss which I imagine is just the pitot and not the tube run, what pressure loss are people getting for the combined pitot/tube run ?

What amount of pressure drop are people experiencing between the fan and test piece, from flow path and measurement losses ?

I am having thoughts of configuring the motors so that I run up to all 12 in parrallel for large volumes at moderate test pressures and being able to change to a parrallel set of six in series with another parallel set of 6 for moderate volumes at high test pressures.

Do 2 vacuum motors in series actually double pressure at the flowrate of a single, or do they behave significantly different ?

Cheers

John

I have been lurking around here for a few days reading what everyone has done to date and I must say this forum and your succeses are a credit to all involved. This information has saved me at least two bench redesigns.

I am embarking on my own flow bench build so that I can investigate a YB Cosworth cylinder head from an English Ford.

I have lashed out and bought 12 of the 491.3.707 motors with flow specs as per the attached chart.

Initially I had thoughts of Laminar Flow Elements or a Thermal Mass Flow Transducer for measuring flow, but it seems orifi and pitot's can be set up in a bench to work accurately. Always thought it odd to use measuring devices that were affected by the turbulence that should be generated by port flow.

I see orifi are commonly setup to use 6" or 13" max pressure loss for measuring flow. What about Pitot's, often stated as 2" insertion loss which I imagine is just the pitot and not the tube run, what pressure loss are people getting for the combined pitot/tube run ?

What amount of pressure drop are people experiencing between the fan and test piece, from flow path and measurement losses ?

I am having thoughts of configuring the motors so that I run up to all 12 in parrallel for large volumes at moderate test pressures and being able to change to a parrallel set of six in series with another parallel set of 6 for moderate volumes at high test pressures.

Do 2 vacuum motors in series actually double pressure at the flowrate of a single, or do they behave significantly different ?

Cheers

John