by Flash » Sat Oct 10, 2009 12:35 am

by Flash » Sat Oct 10, 2009 12:35 am

Well port session #3 is done and flow tested...................

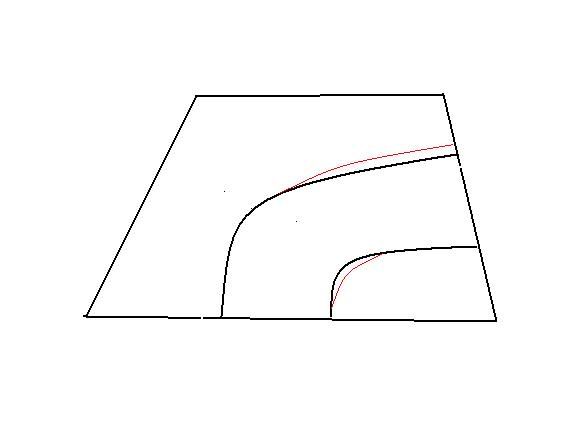

this time i straightened the slow wall, removing the boldge just before the bowl smoothed and shortened the ssr were the wall meets.

Flattened the roof out a little bit more as well as the wall to roof bump, squaring up.................. well. cfm is identical to the last test, except at .500 lift and it gained 3 cfm

no change at 600 lift

all the air speed increased on the slow side, even at the ssr and slowed down slightly in the middle and other side or ssr

Also ground a slight venuri in the bottom of the bowl on the short speed side as well.

Here is a interesting tid bit of info!

After each port session, i wash the head with hot water, wipe dry and then spray the hole head with WD-40.

I wipe the port out before i flow test each time but there is always a thin layer that stays in the port.

What i have noticed !

Exactly 1/2 of the valve heads underside sureface is coated with oil......the other half is Dry!

My cylinder adapter is clear, and the oil is sprayed out on only one side of cylinder.

It is coming out, half of the ssr and the fast wall(prp side ) even after i straightened the slow wall and radious up the ssr at that wall.

If i had to do it over again i would not, remove the bump on the roof or straighten the bump on the slow wall.........It just help to send it over to the side it likes any ways :p

When i start on my next intake port, i will test these ideas..........as i will start backward from this port.

Gordon