Page 1 of 1

Posted:

Fri Dec 30, 2005 1:41 pmby JRM

I was thinking when i redo my bench again (still dragging my feet) what about running 4 motors on each side of the main board this way you would only need 1 main opening.

then all i would have to do is run stoppers on the motors that were not in use. For example 4 motors would be on the vacc side. then when i wanted to switch to blow I just shut the 4 off and turn on the other 4

Posted:

Fri Dec 30, 2005 2:59 pmby Thomas Vaught

That is basically the way a SF110 or 120 works except that it uses 2 motors for intake and two motors for exhaust.

Tom V.

Posted:

Fri Dec 30, 2005 3:44 pmby 86rocco

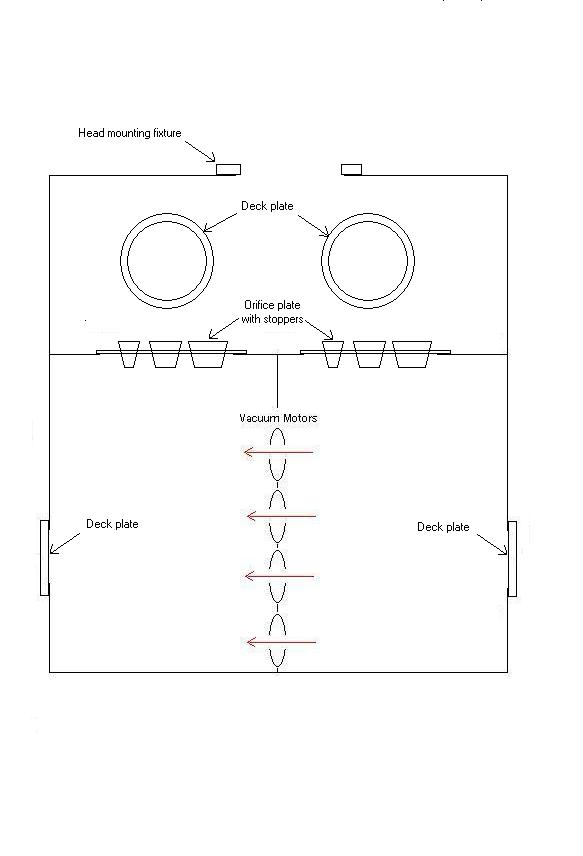

You're not exactly getting the best bang for your buck with the motors arranged that way. But, I understand where you're coming from, I don't like any of the conventional ways of controlling flow direction either. I'm going to try something different, I'll be using 2 orifice plates each with multiple holes, one on the intake side and one on the exhaust, and the orifice plates will be fitted with stoppers and there'll be a door in the form of a marine deck plate on both sides of the airbox, here's a diagram of my design.

To do an intake test, close the intake door, open the door on the exhaust side and pull the appropriate stoppers on the intake orifice plate, to switch sides, open the intake door, close the exhaust door, replace the stoppers on the intake orifice plate and remove the appropriate ones from the exhaust plate.

Air volume control will be acheived by switching motors on or off and for finer adjustments one of the motors will be fitted with a variac for speed control. Also, each motor will be fitted with a check valve to prevent reverse flow when that motor is not in use. For details on the check valve see

Posted:

Fri Dec 30, 2005 5:54 pmby Thomas Vaught

I still say that it one of the simplest designs I have encountered.

No corrections for the difference in the plates too. Each one will

have its own calibration.

Tom V.