Orifice plate construction and sealing

17 posts

• Page 1 of 2 • 1, 2

There have been a several threads lately that have made reference to the rotating orifice as used in the Mercdog design and the related leakage problem. Which of the commercially available flowbenches use a rotating disc and how do they deal with this problem?

Here's what I'm thinking of doing to get around it, any and all comments or suggestions are welcome.

I plan to sandwich the rotating plate between two sheets of UHMW PE backed up with a piece of 1/4" aluminium plate to keep everything nice and flat, I'll have a small spring loaded detent to center the orifice plate in the opening a hopefully by allowing the plate to float very slightly between the sheets of PE, the air pressure will push the orifice plate up against the sheet of PE on the opposite side thus providing a fairly tight seal.

Here's what I'm thinking of doing to get around it, any and all comments or suggestions are welcome.

I plan to sandwich the rotating plate between two sheets of UHMW PE backed up with a piece of 1/4" aluminium plate to keep everything nice and flat, I'll have a small spring loaded detent to center the orifice plate in the opening a hopefully by allowing the plate to float very slightly between the sheets of PE, the air pressure will push the orifice plate up against the sheet of PE on the opposite side thus providing a fairly tight seal.

- 86rocco

- Posts: 319

- Joined: Fri Mar 12, 2004 9:11 am

Interesting thoughts, Rocco.

I was trying to figure out a way to seal it up, and still be able to turn the plate. I was trying to figure a way to use a diaphram spring like a clutch to seal it and release it. Time is flying by and I haven't had an opportunity to really investigate the idea. For that reason, I am currently leaning towards the rubber stopper idea. Most of the panels for the bench are cut, and next thing to do is biscuit cut and fit them together. That means that the time is fast approaching to make some final decisions.

I also considered routing a groove around the pie shaped opening, and making an o-ring to put in it, but decided it wouldn't last, the holes would probably tear the o-ring sooner or later.

On the surface of things, the rotating disc idea appeals to me because it means fast range changes with the twist of a wheel, but the stopper idea would entail powering down to remove the acces plate for each range change, a little more tedious. In the final equation, though, I want a bench that repeats consistently and doesn't have any wild leakage problems to cause me to lose confidence or credibility in my tests.

I would like to hear from some of the other members on the forum and learn how they dealt with these issues, or what their thoughts are.

I was trying to figure out a way to seal it up, and still be able to turn the plate. I was trying to figure a way to use a diaphram spring like a clutch to seal it and release it. Time is flying by and I haven't had an opportunity to really investigate the idea. For that reason, I am currently leaning towards the rubber stopper idea. Most of the panels for the bench are cut, and next thing to do is biscuit cut and fit them together. That means that the time is fast approaching to make some final decisions.

I also considered routing a groove around the pie shaped opening, and making an o-ring to put in it, but decided it wouldn't last, the holes would probably tear the o-ring sooner or later.

On the surface of things, the rotating disc idea appeals to me because it means fast range changes with the twist of a wheel, but the stopper idea would entail powering down to remove the acces plate for each range change, a little more tedious. In the final equation, though, I want a bench that repeats consistently and doesn't have any wild leakage problems to cause me to lose confidence or credibility in my tests.

I would like to hear from some of the other members on the forum and learn how they dealt with these issues, or what their thoughts are.

Jim

- gofaster

- Posts: 237

- Joined: Fri Jul 01, 2005 6:39 pm

- Location: Indiana

Rocco,

That's similar to what I came up with. The spring is just located further up on the shaft. The angled front section of the bench and a washer welded to the shaft with the spring sandwiched in between.

That's similar to what I came up with. The spring is just located further up on the shaft. The angled front section of the bench and a washer welded to the shaft with the spring sandwiched in between.

- larrycavan

- Site Admin

- Posts: 1183

- Joined: Fri Apr 01, 2005 4:40 pm

I wonder if one could design some sort of clamp and release mechanism that would seal the orifice in use to o-rings on either side.

Release to select an orifice, then clamp to seal.

Seems to me some sort of absolutely positive sealing design like this would be the only way to achieve zero leakage between ranges when using a rotating orifice disk.

Release to select an orifice, then clamp to seal.

Seems to me some sort of absolutely positive sealing design like this would be the only way to achieve zero leakage between ranges when using a rotating orifice disk.

Jesse Lackman

- Jesse Lackman

- Posts: 106

- Joined: Thu Mar 17, 2005 9:31 pm

- Location: ND

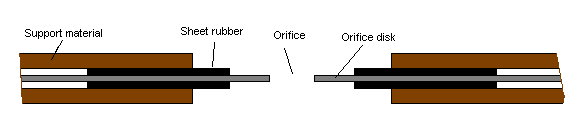

It seems to me that some sheet rubber gasket material is all that is needed to form a seal. The air pressures in the cabinet should do the sealing. The disk should not even have to be tight between the sheet rubber gaskets.

<a href="http://www.flowperformance.com/images....ce disk</a>

<a href="http://www.flowperformance.com/images....ce disk</a>

- Mouse

- Posts: 308

- Joined: Wed Jan 21, 2004 8:45 pm

Quote:

"On the surface of things, the rotating disc idea appeals to me because it means fast range changes with the twist of a wheel, but the stopper idea would entail powering down to remove the acces plate for each range change, a little more tedious".

I sure hope you are powering down the bench before you are trying to move to the next range! LOL!

Depending on the spacing between the "next orifice" you are trying to get to, you might suck the fluid out of your manometers (unless you have a FP-1) or suck the bench in!

I always shut down the bench on a range change.

I keep observing the different designs proposed on the rotating orifice deal and I keep hearing about the leakage problems. Any

device that moves wears out over time. Stoppers are cheap vs tearing the bench apart to fix leaks.

If you had to have a rotating disc deal trapped in a "support structure" like Rocco, Larry, and Mouse recommend then I would have a rotating disc mounted vertically with the recommended rubber material covering both sides of the opening for the orifice holes and a second seal of the same material around the edges of the square orifice support structure.

I would still have the single rod turning the orifice disc but would use FOUR rods with overcenter clamps or wingnuts to tighten the support structure after the range was set. The wing nuts or the overcenter clamps could be out of the way on the side of the bench.

Tom V.

ps Harold Betties (of Superflow) and I discussed this deal and he really liked the SF 1200 stopper bench deal. His words were "Unless the stoppers were impregnated with diamond dust the orifices would never wear with range changes and rubber stoppers are cheap"

"On the surface of things, the rotating disc idea appeals to me because it means fast range changes with the twist of a wheel, but the stopper idea would entail powering down to remove the acces plate for each range change, a little more tedious".

I sure hope you are powering down the bench before you are trying to move to the next range! LOL!

Depending on the spacing between the "next orifice" you are trying to get to, you might suck the fluid out of your manometers (unless you have a FP-1) or suck the bench in!

I always shut down the bench on a range change.

I keep observing the different designs proposed on the rotating orifice deal and I keep hearing about the leakage problems. Any

device that moves wears out over time. Stoppers are cheap vs tearing the bench apart to fix leaks.

If you had to have a rotating disc deal trapped in a "support structure" like Rocco, Larry, and Mouse recommend then I would have a rotating disc mounted vertically with the recommended rubber material covering both sides of the opening for the orifice holes and a second seal of the same material around the edges of the square orifice support structure.

I would still have the single rod turning the orifice disc but would use FOUR rods with overcenter clamps or wingnuts to tighten the support structure after the range was set. The wing nuts or the overcenter clamps could be out of the way on the side of the bench.

Tom V.

ps Harold Betties (of Superflow) and I discussed this deal and he really liked the SF 1200 stopper bench deal. His words were "Unless the stoppers were impregnated with diamond dust the orifices would never wear with range changes and rubber stoppers are cheap"

- Thomas Vaught

- Posts: 465

- Joined: Fri Feb 18, 2005 5:36 pm

- Location: Michigan

The problems are far fewer if the airflow through the measurement orifice always flows in one direction only.

My bench has two test holes in the bench top, one sucks and the other blows. No need to reverse the flow through the whole bench. It has vastly simplified everything doing it that way.

My bench has two test holes in the bench top, one sucks and the other blows. No need to reverse the flow through the whole bench. It has vastly simplified everything doing it that way.

- 84-1074663779

My orifice turret is two feet in diameter and made from melamine (laminex) covered particle board. The white stuff they make kitchen cabinets from. It provides a very hard wearing flat tough smooth surface. This rotates against a flat melamine bulkhead with a single self aligning ball bearing. It is very lightly spring loaded, but air pressure holds it flat with zero measurable leakage.

A extension shaft, using a car steering column universal joint at the turret, pokes out the right hand side of my bench, and a car steering wheel is used to rotate the turret.

A spring loaded roller on the outside diameter of the orifice turret "clicks" into position to positively locate each orifice by feel. I have cut eight 3.5" holes in the turret with a holesaw, and into this press eight measurement orifices made from 90mm PVC pipe blanking ends. (note 90mm is a tight push fit into a very slightly oversized 3.5" hole)

Each orifice is very quickly interchangeable and removable in the turret, and these same orifices also fit into either of my test holes. Very simple and convenient. I can get as many blank orifices as I want very cheaply from the local plumbing shop and quickly bore out any sized hole on the lathe.

A extension shaft, using a car steering column universal joint at the turret, pokes out the right hand side of my bench, and a car steering wheel is used to rotate the turret.

A spring loaded roller on the outside diameter of the orifice turret "clicks" into position to positively locate each orifice by feel. I have cut eight 3.5" holes in the turret with a holesaw, and into this press eight measurement orifices made from 90mm PVC pipe blanking ends. (note 90mm is a tight push fit into a very slightly oversized 3.5" hole)

Each orifice is very quickly interchangeable and removable in the turret, and these same orifices also fit into either of my test holes. Very simple and convenient. I can get as many blank orifices as I want very cheaply from the local plumbing shop and quickly bore out any sized hole on the lathe.

- 84-1074663779

17 posts

• Page 1 of 2 • 1, 2

Return to Orifice Style bench discussion

Who is online

Users browsing this forum: No registered users and 19 guests