Page 1 of 2

Posted:

Wed Nov 30, 2005 5:49 pmby 86rocco

For quite a while now I've been pondering what my flowbench will look like, at first I was just going to build a MSD style bench but there were too many details that need to be just right for it to work properly, the valves, the rotating orifice disk and all the related leakage problems. So I've decided to make my bench just about as simple as it could possibly be, no valves and no rotating disc.

I think I've got my design, tell me what you think of this:

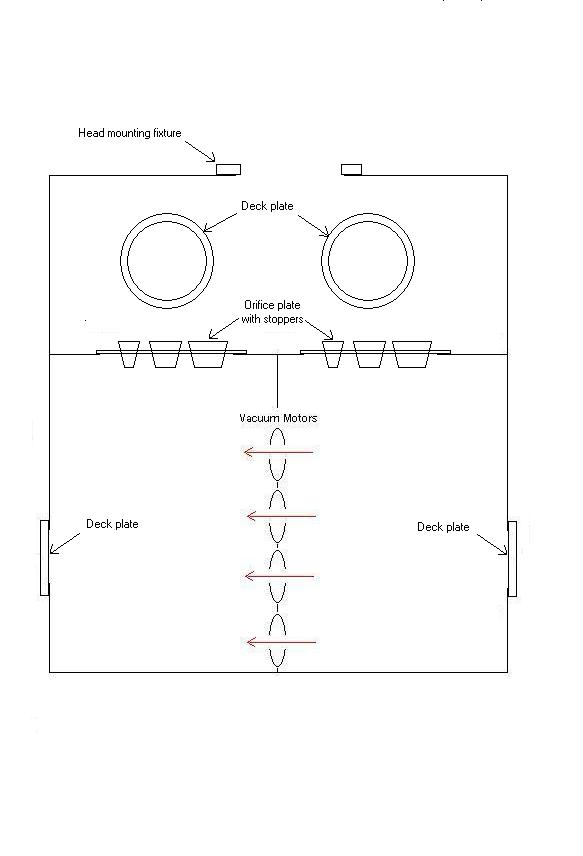

For ease of construction, it'll be made in two sections an upper and a lower section. The lower section will contain the motors, they'll be mounted horizontally on the dividing wall, with flapper valves to limit reverse flow through the motors when they're not running. There'll be room for nine motors. There'll be a door on each side and two holes on top near the front edge for one exhaust and one for intake.

The upper section will be the plenum, there'll be two holes in the bottom that line up with the holes in the lower section. Each hole will be have a clamping fixture to hold either a plate with an orifice or a solid plate. At first I'll start with a few different orifice plates each having only one hole, later I'll experiment with plates that have multiple holes and stoppers to select the ranges. There'll be a door or decking plate on the front for easy access to the plates, and internal baffles in both halves to direct the airflow.

Flow control will be acheived with a variac controlling one motor and the remaining motors switched individually. And flow direction is achieved by swapping the orifice plate and solid plate from side to side.

Posted:

Wed Nov 30, 2005 9:38 pmby larrycavan

Rocco,

The only thing I would comment on is that for porting cylinderheads, I don't see the need for orifices with multiple holes unless space is a problem. With 9 motors you should have enough power to pull good depression across a fairly large orifice. I have no doubt you can achieve the accuracy with a multiple hole orifice but I can't see a reason to actually need to...

JMO

Larry C

Posted:

Wed Nov 30, 2005 10:34 pmby 86rocco

You might very well be right. One of the reasons I've designed it like I did is because it's adaptable, if I don't need multiple orifices, or the size of the orifices I've chosen are all wrong, I just make a new plate with an appropriately sized orifice and swap it out for the old one. I wouldn't need to re-design anything or disassemble anything

Posted:

Wed Nov 30, 2005 10:43 pmby larrycavan

Posted:

Fri Dec 09, 2005 4:23 pmby 86rocco

Here you go, the sketch is a little bit crude, I haven't shown any of the internal baffling but other than that, all the main features are there. I've decided to go straight to the multi-hole orifice plate with stoppers set-up, if for some reason that proves to be unsatifactory, it'll be easy enough to retrofit it with a clamping fixture of some sort for single orifice plates.

Posted:

Fri Dec 09, 2005 5:15 pmby Mousehouse1

Why not install one 6 or 8" deck plate in the front of the bench instead of two?

What are you going to do about exhaust flow? Are you going to put the stoppers on the other side of the orifice plates?

Don't use cheap deck plates. They will leak. I have some I bought for $4.50 each and they leak badly. I just finished installing some beckson deck plates and they fit and look alot better. The were 3 times as much but they are worth it.

Posted:

Fri Dec 09, 2005 5:44 pmby 86rocco

Deck plates are not that expensive and they're easy to install, two would probably be more convenient but I haven't decided for certain yet I may only put in one. As for the stoppers in the exhaust side, I'm hoping that I can get away with putting them in from the top side, it'll be the very first thing I test once I get it built, although, I think it'll probably be okay. The pressure difference across that plate will never be much more than 10 or 12" WC so the force the largest stopper will only be about 2 lbs, if that proves to be too much a re-design will be necessary.

The deck plates I got were pretty cheap but but they look pretty good, they're heavy molded pvc with not a lot of flex to them, they're the thread in type not the pop-out type and there's a rubber o-ring seal. I hope they'll do.

Posted:

Fri Dec 09, 2005 7:52 pmby Mousehouse1

Mine deck plates don't have a name on them. They were pretty flexible. The beckson plates are built better and should work out fine. I hope yours work out. I think I have $60 in 6 plates with shipping. I went with the clear covers so I could see inside the bench.

What are you using for a front panel. I used plexi-glass but it moves a little when I try and do a leak test. I am most likely going to replace it with aluminum.

Posted:

Fri Dec 09, 2005 8:31 pmby 86rocco

All of the structural elements of the bench are going to be 3/4" particle board and it will covered with melamine laminate. The front panel with the switches etc. will be thin aluminium. I have someone who says he can get me aluminium plate, if he comes through for me, the top will be 3/8" or 1/2" aluminium plate

Posted:

Fri Dec 09, 2005 11:41 pmby Thomas Vaught

Ed, if you are using a staged motor deal or a veriac motor type controller you can't get much better or simplier than what you have posted.

Tom V.

Posted:

Sat Dec 10, 2005 1:14 amby 86rocco

That's the plan. Simplicity was one of the driving forces behind this design. I'm anxious to get this thing built to see how it works. I'd like some sort of check valve on each motor,once I figure out exactly how I'mgoing to do that, I'll be ready to get her done.

Posted:

Sat Dec 10, 2005 3:48 amby Nick

I have stoppers in my bench, and they stay in just fine when exhaust testing. I just push them in good and tight. I went up to 36" and they stayed in. My largest orifice is 2.513.

Posted:

Sat Dec 10, 2005 10:32 amby Mousehouse1

Rocco I think Mouse was working on something like that. I don't know if he ever finished them or not.

Posted:

Sat Dec 10, 2005 12:50 pmby 86rocco

I remember seeing a post regarding that not long ago. I think I'm going to build a box on the intake side of each motor with a hinged aluminium backed rubber flapper, heavy enough to fall closed under gravity but light enough to be easily blown open when the motor is running. I hopely over the next week or so, I'll work out the precise details and build a prototype.

Posted:

Sat Dec 10, 2005 5:00 pmby cboggs

Question gang,

All this talk of the multi orifice plate with rubber stoppers, ..

and of course I'm having problems with the orifice disc in my Mercdog

style bench, ..

I was thinking of having multi orifice plates made, 6"x6" square and make a

fixture to clamp them in the bench, .. but, ..

could I just take the entire orifice disc out, .. cut a big square hole, ..

make a plate with say 4 holes in it, .. and put it in place????

If the rubber stoppers stay in under 38" of exhaust pressure I'd say

that is a fairly simple / easy way to solve this problem once and for all.

Still using the "salad" bowl valves that seem to work just fine, ..

I use the Performance trends software so I ordered a box from them, ..

ordered the "high pressure" box so I'll take the Manometers off all together.

Curtis