Page 1 of 1

Posted:

Thu Oct 29, 2009 5:51 pmby jfholm

I hope nobody minds me starting a thread just for this so it is easy to search. Was a great topic.

Flash, what I am going to use for the wire for my flow balls is some .060" welding rod from my tig welder. It is plenty stiff.

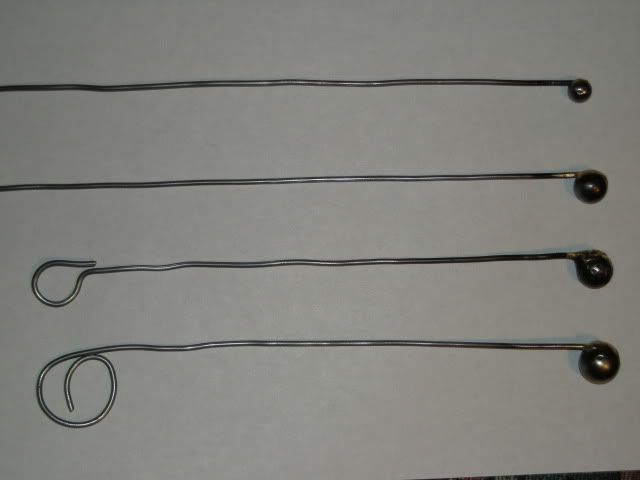

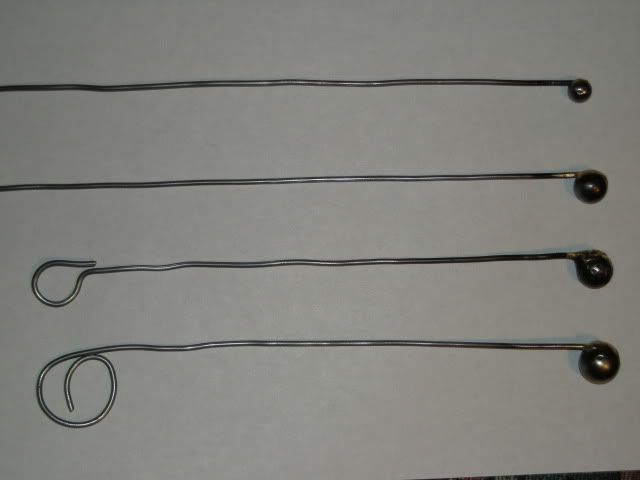

Thanks to Bruce, here is a picture of the start of my flow balls.

John

Posted:

Fri Oct 30, 2009 9:43 amby jfholm

I forgot to mention the best part! This wooden beads, all of them, was $4.00. Plus a couple of dollars for welding rod and you will have all the flow balls you want for under $10. I also like the idea of the lighter wooden beads as they should be more sensative to the air movements.

John (loving the cheap way out!)

Posted:

Fri Oct 30, 2009 9:58 amby Flash

Good idea!

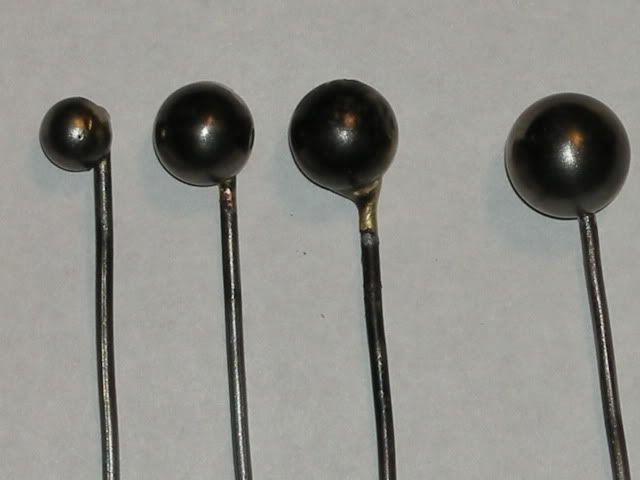

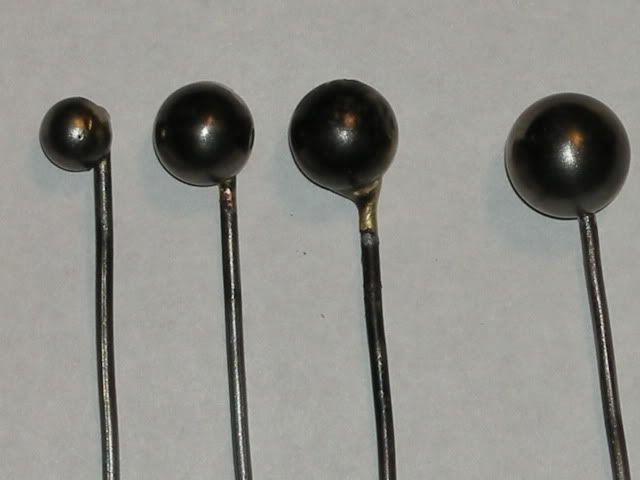

I will repost my pic's here as well.

I took a steel ball, cut a groove, with dye grinder and a "cut off" wheel. Brazed wire in groove, then, to the wire wheel for smoothing.

Posted:

Fri Oct 30, 2009 10:00 amby Flash

John, have you made yours yet?

How due they float in the port and how well can you control them.

Posted:

Fri Oct 30, 2009 11:31 amby slracer

At the risk of being thought of as having "an elevator that doesn't go all the way to the top", I am going to suggest something here. In the older thread, it was stated that we are looking for areas where a flow ball doesn't disturb the flow (or only slightly disturbs it). It seems to me that if we are looking for dead or low speed areas of an inlet (or exhaust), we need to be able to put a flow ball somewhere we want to investigate and have it stay there. That means the support wire needs to be quite stiff to AVOID flailing around in the duct, probably stiffer than a velocity probe as the larger balls will have more force on them at the same air speeds. If the ball is moving around, it is acting like a string to help visualize the flow, but NOT allowing any measurements to be made. Does this make sense to anyone? Just looking for "the truth" (which we all know is "out there"). :p -- Doug

Posted:

Fri Oct 30, 2009 12:51 pmby Flash

Posted:

Fri Oct 30, 2009 2:10 pmby jfholm

I have not done anything yet. My wife is in the hospital and I have been there all the time.

John

Posted:

Fri Oct 30, 2009 2:14 pmby jfholm

btw Doug is on the right path to thinking. Ideally you would want the same air flow through the port every where you tested. Same FPS etc. That is what you are striving for. Keep in mind you will not get it, but what you do to get the port to "trend" in that direction is what you want to do and test for.

John

Posted:

Fri Oct 30, 2009 4:46 pmby larrycavan

John,

Hope your wife is feeling better.

Larry C

Posted:

Fri Oct 30, 2009 6:13 pmby jfholm

Larry,

Thanks for your concern. She had her right knee replaced. She was very nervous at the thought but now that it is over it was not as bad as she thought, still painful though. They had some excessive bleeding while on the table and almost had to do a transfusion, but did not have to. She is now smiling, it is amazing what good drugs can do

John

Posted:

Sat Oct 31, 2009 12:36 pmby slracer

John, My best to your wife also! My wife had a hip replacement a couple of years back so I know what YOU are going to go through!  -- Doug

-- Doug

Posted:

Sat Oct 31, 2009 1:18 pmby jfholm

Thanks Doug!

I guess us making flow balls is nothing compare to going in and doing a knee. I watched a couple of videos on youtube and it is quite the process. My wife's Dr. is amazing. He came in and spent at least 30 minutes with us showing the Xrays and telling us in detail how he did it. Truly amazing. btw he used aligning jigs and everything. Good machinist he is! :;):

John