200 CFM Research

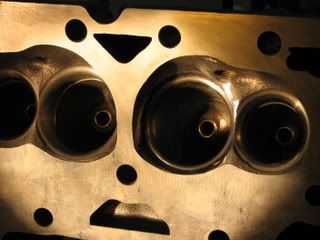

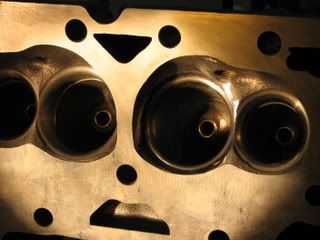

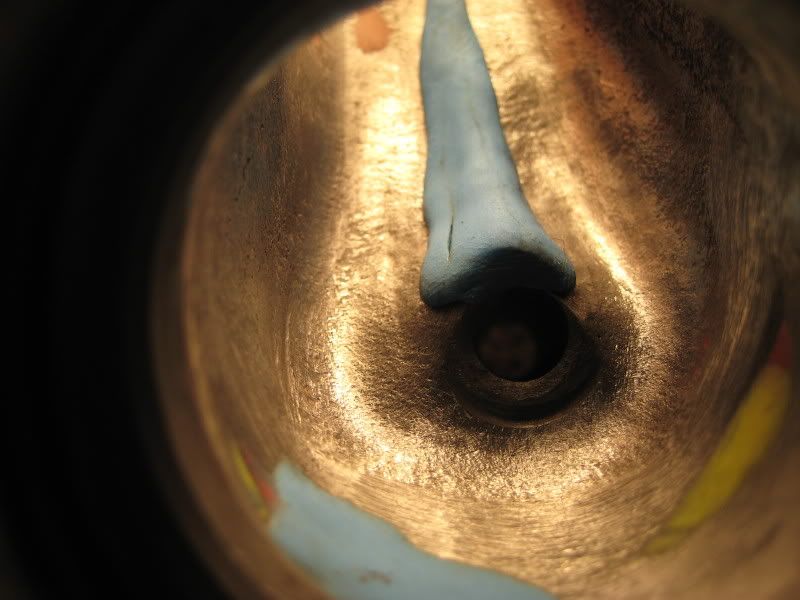

Somehow this photo got deleted. The pencil is pointing toward the shroud dye marking that runs the length of the curve. Clearly shows that air and dye are existing that section. Can I conclude that for .100 lift the priamry flow is from the chamber shroud area to the plug area only and that the other areas (unmarked) on the valve and chamber are "out of the loop"?

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Have you tried laying the chamber back where I have put the yellow arrow? That ridge could be laid back and I think it would help unshroud your valve at that area. That can be a critical area.

John

compare to my small block Chev

John

compare to my small block Chev

It is a wise man that learns from his mistakes, but it is a wiser man that learns from the mistakes of others.

- jfholm

- Posts: 453

- Joined: Sat Jan 17, 2009 7:12 pm

- Location: Utah, USA

John, you have said it "That is a critical area". Every change that we make it is a compromise, by laying it back you will have less area and when the piston comes to TDC it is going to be less swirl. Mixture motion you need it not as much in the high RPM.

- racehead-1

- Posts: 30

- Joined: Mon Mar 10, 2008 7:29 am

- Location: Portugal

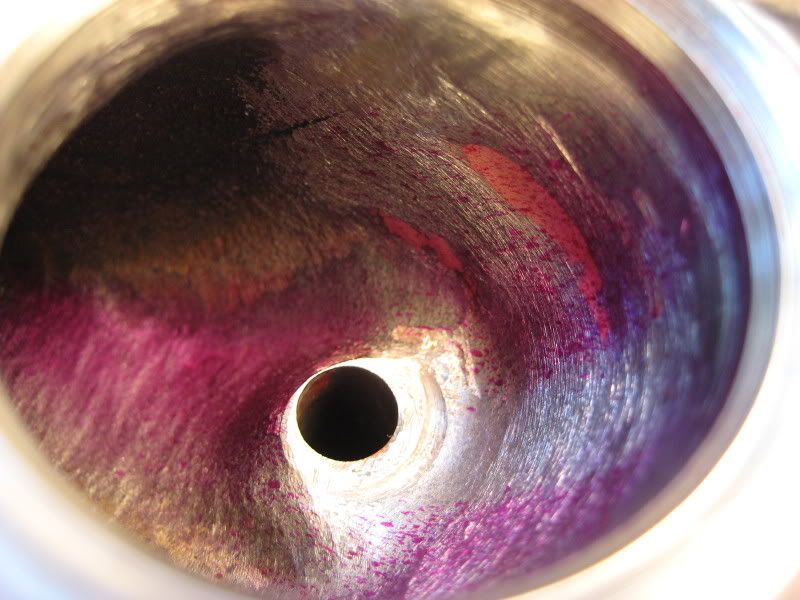

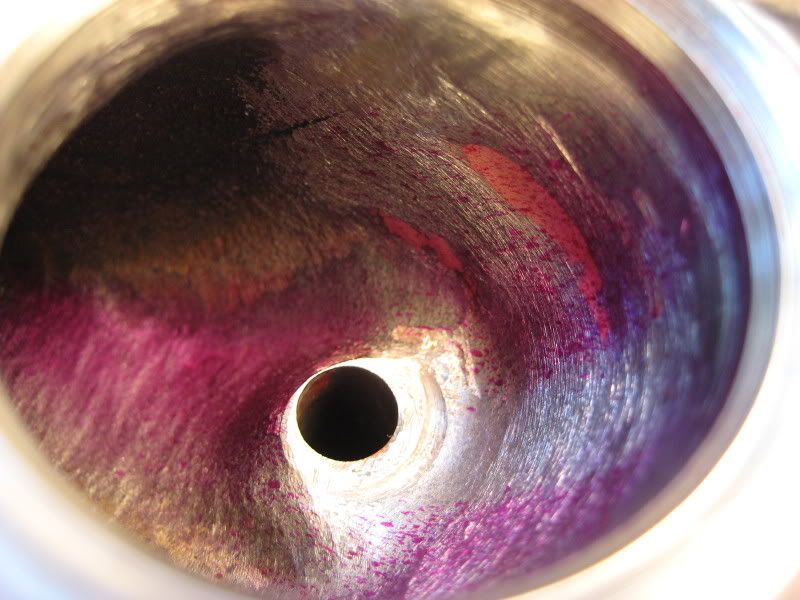

Ok, will take that ridge down some. It does cast a shadow to the dye flow. I made additional wet spray tests at .200/.450/and .550 lifts. The basic pattern continued inside the port and bowl with less or no markings on the shrouded chamber side and no detection on the SSR. The bias still toward the plug and big channel to half the bowl for some reason.

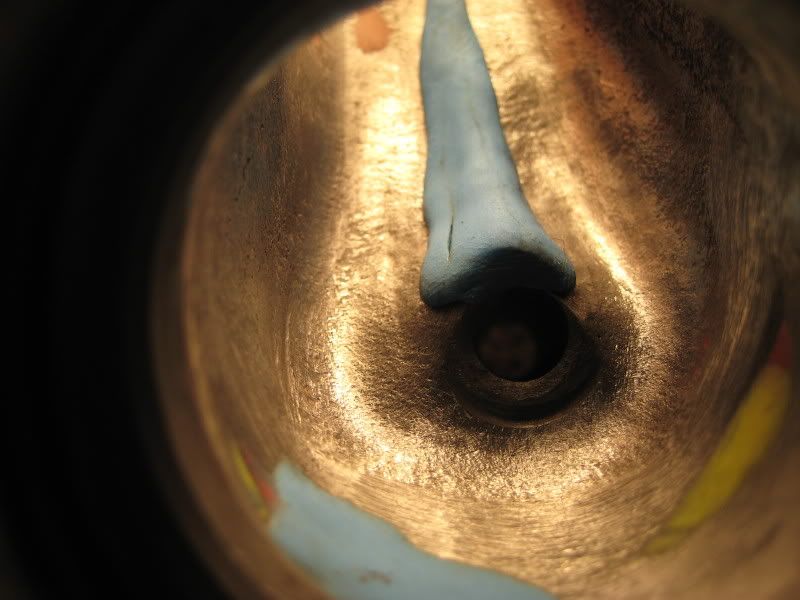

Here is the .450 view.

And here is the .550 view.

As for the swirl direction in the cylinder it is CW.

Today I tried something different. I installed the intake manifold to see if this changed direction of the dye. It certainly did. I tested at .450 lift, full 28" wc plus to insure it would pull the spray real strong, and gave it about 8 triggers to get most of it into the manifold port. First thing I noticed was the heavy markings on the floor entrance as if the air is slamming down more toward the floor. And it marked the wall leading to the pushrod turn, but no markings on the same wall after the turn is made. The other wall was bare and the roof also other than the roof entry edge.

The other surprise was the even bias on the bowl long side wall. It split pretty much down the middle on the bowl with

some shadow from the pushrod. And the new channel was showing markings for the first time.

So adding the manifold has changed the results a lot.

Anothe view of markings on the new channel and when I inspected the valve it showed for the first time fan markings in the direction of flow toward the exhaust. Plug was still getting its markings too.

Here is the entrance after removing the manifold. Rather heavy on the floor entrance and note the markings on the wall leading to the PRt. That wall was untouched without the manifold. The adjacent wall that has the head bolt turn was mark free all the way down.

I think I need a PTS wet flow bench like Chris now.

Here is the .450 view.

And here is the .550 view.

As for the swirl direction in the cylinder it is CW.

Today I tried something different. I installed the intake manifold to see if this changed direction of the dye. It certainly did. I tested at .450 lift, full 28" wc plus to insure it would pull the spray real strong, and gave it about 8 triggers to get most of it into the manifold port. First thing I noticed was the heavy markings on the floor entrance as if the air is slamming down more toward the floor. And it marked the wall leading to the pushrod turn, but no markings on the same wall after the turn is made. The other wall was bare and the roof also other than the roof entry edge.

The other surprise was the even bias on the bowl long side wall. It split pretty much down the middle on the bowl with

some shadow from the pushrod. And the new channel was showing markings for the first time.

So adding the manifold has changed the results a lot.

Anothe view of markings on the new channel and when I inspected the valve it showed for the first time fan markings in the direction of flow toward the exhaust. Plug was still getting its markings too.

Here is the entrance after removing the manifold. Rather heavy on the floor entrance and note the markings on the wall leading to the PRt. That wall was untouched without the manifold. The adjacent wall that has the head bolt turn was mark free all the way down.

I think I need a PTS wet flow bench like Chris now.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

I took that chamber ridge down and it helped. Reflow showed it helped some from .400 up to .600 where it hit slightly over 190 cfm. Then I tried widening the mouth width of the SSR and gave it a tad layback which I thought (to my eyes) it needed based on how I thought it needed to blend better to the 60 cut. Lost cfm across all lifts by 3-5 cfm.

I set it all aside and started a new manometer scale in mm's for the PTS pitot tube. The Dwyer U tube was in inches and scaling was only in 1/8's and I got tired of doubling and possible error from the inch scaling. So the new 100% vertical goes to 36" in mm's and offers finer resolution.

BUT, while testing it out this evening I detected "dead spots" in the bowl. Is this possible? Can air be simple dead or not flowing in certain sections of a bowl? I don't recall detecting dead spots with the U tube manometer.

I thought or wondered if the new DIY manometer was acting up but it is working so fine along the PRt areas and down the middle and along the SSR. So I don't think it is the design.

Anyone ever seen dead areas in the bowl areas? (tom)

I set it all aside and started a new manometer scale in mm's for the PTS pitot tube. The Dwyer U tube was in inches and scaling was only in 1/8's and I got tired of doubling and possible error from the inch scaling. So the new 100% vertical goes to 36" in mm's and offers finer resolution.

BUT, while testing it out this evening I detected "dead spots" in the bowl. Is this possible? Can air be simple dead or not flowing in certain sections of a bowl? I don't recall detecting dead spots with the U tube manometer.

I thought or wondered if the new DIY manometer was acting up but it is working so fine along the PRt areas and down the middle and along the SSR. So I don't think it is the design.

Anyone ever seen dead areas in the bowl areas? (tom)

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Tom,

Yes you will have some parts in the bowl that will be much slower than the other parts. This is the same in my SBC bowls. If you were trying to maintain a cc volume in a port due to class regulations on intake size that is probably where you would fill with epoxy, in the slow areas of the bowl.

Does the flow ever go backwards after you reach a certain lift? If it does you may have to work on the SSR.

John

Yes you will have some parts in the bowl that will be much slower than the other parts. This is the same in my SBC bowls. If you were trying to maintain a cc volume in a port due to class regulations on intake size that is probably where you would fill with epoxy, in the slow areas of the bowl.

Does the flow ever go backwards after you reach a certain lift? If it does you may have to work on the SSR.

John

It is a wise man that learns from his mistakes, but it is a wiser man that learns from the mistakes of others.

- jfholm

- Posts: 453

- Joined: Sat Jan 17, 2009 7:12 pm

- Location: Utah, USA

Made a little more progress but it is very slow. Hitting slightly over 190 @ .600 now. Latest change was an epoxy filled dip in the wall where the head bolt turn has been filed down. I notice the fps is more consistent down the middle of that wall, some variations because the wall is still is not dead flat or straight and I thought ok, that should be a plus. But reflow showed a drop in the cfm across the lifts. So I got to wondering if I should forget about the drop and port for a more consisent air speed down the middle of that wall like others try to get down the middle of the port. It may be dropping because the adjacent wall still has an angle turn and makes the port an expansion area after the PRt. Of course when you track the speed down that PRt expansion wall it takes a much larger fps drop. But at least for now I do have the fps at the PRt under 350 for the first time. Around 328 fps at .450 reference lift. No it doesn't show a backing up yet. Just stops gaining arond .600"

I took a break from it all and went racing this afternoon for the first time. Car went 10.50 @ 129 and then a 10.45 @ 129.13.

The PTs bonnet hat performed well on these 180 cfm heads helped with 8 lbs of boost.

Here is the 10.45 run. My A/F meter failed again after a new sensor replacment. Always something. Here is the video of run # 2. A high dollar ProMod hit the wall after the eighth so I decided to go home while I still had a car.

Run 2: 1.525 4.334 6.687 @ 104.17 8.721 10.451 @ 129.13

I took a break from it all and went racing this afternoon for the first time. Car went 10.50 @ 129 and then a 10.45 @ 129.13.

The PTs bonnet hat performed well on these 180 cfm heads helped with 8 lbs of boost.

Here is the 10.45 run. My A/F meter failed again after a new sensor replacment. Always something. Here is the video of run # 2. A high dollar ProMod hit the wall after the eighth so I decided to go home while I still had a car.

Run 2: 1.525 4.334 6.687 @ 104.17 8.721 10.451 @ 129.13

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

[color=#000000]Tom,

I feel you are doing the right thing to watch your velocities more than CFM. In one thread Larry Meaux had stated that he re-did a set of SBC heads on a SS NHRA racer. He said the velocity was way too fast. He redid the heads and got the velocities down where they should be and did not pick up 1 cfm. They took the car back out and it was .5 fast and a bunch of mph and yet they did not pick up 1 cfm.

btw he likes to see velocities in the 260 fps on the intake for standard type heads like 23

I feel you are doing the right thing to watch your velocities more than CFM. In one thread Larry Meaux had stated that he re-did a set of SBC heads on a SS NHRA racer. He said the velocity was way too fast. He redid the heads and got the velocities down where they should be and did not pick up 1 cfm. They took the car back out and it was .5 fast and a bunch of mph and yet they did not pick up 1 cfm.

btw he likes to see velocities in the 260 fps on the intake for standard type heads like 23

It is a wise man that learns from his mistakes, but it is a wiser man that learns from the mistakes of others.

- jfholm

- Posts: 453

- Joined: Sat Jan 17, 2009 7:12 pm

- Location: Utah, USA

Thanks, that is what I was trying to sort out. I haven't dug out the epoxy yet. It's a pain to get it smoothed down so removing it to confirm that the cfm comes back is on hold. But I did notice less swing in the fps as I probed the middle wall line from entry to beyond the headbolt turn. When one has never flowed an ideal port or a port that is behaving as it should behave, it is a little hard to research on how your port should be doing or behaving. The heads on the above race motor have less port volume and CSA than this cut up experimental test head and the fps is higher in those heads and yet the engine (IMHO) seems to like the smaller CSA high speed air port. Though the cfm numbers are not impressive from a bench point of view. Guess I want know until I track test on a pair of heads modeled after the red head porting to really know if they are better.

But just seeing the fps settle down better along that wall got me to thinking, Ok, from here on think airspeed balance as well as max cfm.

But just seeing the fps settle down better along that wall got me to thinking, Ok, from here on think airspeed balance as well as max cfm.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Turbo motors like smaller ports than NA motors. The reason is velocity limit related.

The speed of sound limits the maximum port velocity, and the flowbench velocity target is some percentage of that maximum.

In terms of m/s of ft/s, the speed of sound (mach 1) inside the port/manifolding is different to the speed of sound outside the port/manifolding/engine/engine bay/car. Both locations are still mach 1 but the m/s or ft/s value of mach 1 is quite different.

We test on a bench at ~14.7psia +/- about 1 PSI in most cases.

Your engine sees ~14.7+8=~22.7psia. That extra 8psi and different air temps, changes the speed of sound inside the ports significantly enough for the flowbench measured target port velocity to be increased over what the NA goal is.

Don't be to concerned that CFM on the bench drops with an increase in velocity, typically the speed limit, measured in ft/s or m/s, has increased in a running turbo application.

Just my opinion at this moment in time.

The speed of sound limits the maximum port velocity, and the flowbench velocity target is some percentage of that maximum.

In terms of m/s of ft/s, the speed of sound (mach 1) inside the port/manifolding is different to the speed of sound outside the port/manifolding/engine/engine bay/car. Both locations are still mach 1 but the m/s or ft/s value of mach 1 is quite different.

We test on a bench at ~14.7psia +/- about 1 PSI in most cases.

Your engine sees ~14.7+8=~22.7psia. That extra 8psi and different air temps, changes the speed of sound inside the ports significantly enough for the flowbench measured target port velocity to be increased over what the NA goal is.

Don't be to concerned that CFM on the bench drops with an increase in velocity, typically the speed limit, measured in ft/s or m/s, has increased in a running turbo application.

Just my opinion at this moment in time.

Cheers

John

John

- jsa

- Posts: 189

- Joined: Wed Jul 05, 2006 3:13 am

- Location: Australia

Thanks, that makes sense to me. I understood it because Einstein said something similar on the speed of light both going and coming in reference to time and location or something like that. Things are relative and not always nailed down. Their should be some equation that exists to correlate boost pressure to air speeds for given temperatures and CSA of a port. Nature likes math. I might ask this question over on speedtalk. tom c

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

I got some of the flow back by reshaping a divider wall between the two channels. For some reason it prefers that divider slope. It went:

.100 71.6

.200 130.2

.300 163

.350 173.8

.400 180.9

.450 187

.500 189

.550 192

.600 193

.650 195.1

Port volume came in at 145 cc

PRt:

277 305 328

278 300 328

278 303 326

Down the middle I was getting 277 / 303/ 308/ 312

Mold was made yesterday and will be removed today. Here is the divider that helps. It made up for what the dip fill took away. And I added a clay fill on a casting pit that was to deep to blend as a radius. That helped out too.

Headbolt turn dip fill.

.100 71.6

.200 130.2

.300 163

.350 173.8

.400 180.9

.450 187

.500 189

.550 192

.600 193

.650 195.1

Port volume came in at 145 cc

PRt:

277 305 328

278 300 328

278 303 326

Down the middle I was getting 277 / 303/ 308/ 312

Mold was made yesterday and will be removed today. Here is the divider that helps. It made up for what the dip fill took away. And I added a clay fill on a casting pit that was to deep to blend as a radius. That helped out too.

Headbolt turn dip fill.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

I went and talked to my friend Bill Jones here in Salt Lake. He has a self published porting log/journal that he has made and sells. He actually has a section on a set of Stude' heads like yours that he did. He tests at 25" H2O and was able to get 203 cfm out of those. This converts to 214 cfm at 28". He has 8 or 9 pages in that book just on what he did to those Stude' heads. If you wanted to buy his book you can email him at fwillyj@comcast.net

We also got talking about turbo charging. You need to remember that with turbo charging you are increasing the density of the air in other words the air you are putting in gets heavier. The specfic gravity of the air increases. Normal air at sea level is around .075 lbs per cubic foot. Now if you put some major boost on it like 30 lbs then that same air can now weigh .266 pounds per cubic foot - the heavier air is, the slower it will move.

Now to get an increase in the volume of flow you either increase the size of the hole or increase the pressure. Increasing the pressure only works up to a point of saturation then it does not matter how much pressure you put on a hole it will only flow so much, a carb jet as an example. So the next thing you do is increase the size of the hole.

Finding that sweet spot is the problem. Now I have a friend that is running a Honda Civic that is turbo'd and he runs 40 lbs of boost. He runs 9.40 at 149 mph here in Salt Lake. He is running 2.5l that is 152 cid. He runs huge ports.

I hope some of this helps.

John

We also got talking about turbo charging. You need to remember that with turbo charging you are increasing the density of the air in other words the air you are putting in gets heavier. The specfic gravity of the air increases. Normal air at sea level is around .075 lbs per cubic foot. Now if you put some major boost on it like 30 lbs then that same air can now weigh .266 pounds per cubic foot - the heavier air is, the slower it will move.

Now to get an increase in the volume of flow you either increase the size of the hole or increase the pressure. Increasing the pressure only works up to a point of saturation then it does not matter how much pressure you put on a hole it will only flow so much, a carb jet as an example. So the next thing you do is increase the size of the hole.

Finding that sweet spot is the problem. Now I have a friend that is running a Honda Civic that is turbo'd and he runs 40 lbs of boost. He runs 9.40 at 149 mph here in Salt Lake. He is running 2.5l that is 152 cid. He runs huge ports.

I hope some of this helps.

John

It is a wise man that learns from his mistakes, but it is a wiser man that learns from the mistakes of others.

- jfholm

- Posts: 453

- Joined: Sat Jan 17, 2009 7:12 pm

- Location: Utah, USA

Yes that is a great help. Something I never was aware of in my thinking. CFM is volume and doesn't factor in mass or the weight. If it were a fluid I suspose one could think thicker viscosity. I have Bill's book here and used some of the points as a guide. That little book has a lot of good data in it.

I got my mold out and in the process of evaluating it. I see some areas that need some attention that I didn't pay much attention to before. (tom)

I got my mold out and in the process of evaluating it. I see some areas that need some attention that I didn't pay much attention to before. (tom)

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Who is online

Users browsing this forum: No registered users and 2 guests