Mark, As we discussed last evening while you were here, the nice thing about building a seperate blower box is the ability to change blowers for your bench. If you build with smaller blower motors and then sometime later upgrade to a larger single blower you don't have to change your bench all around as the blower box is seperate from the main bench.

Thanks again for letting me look at your blower gave me a good idea of how they are constructed which will assist me in "my project".

new member - My first flow bench

26 posts

• Page 2 of 2 • 1, 2

no problem bruce After our talk and talking to some people on here I am going to build a test box for this blower this week and maybe see If I can bring it down and see how much this blower will actually pull at 28in. I have to find a good way to make the box out of the leftover wood from the bench. I figure if it can't pull enough pressure I will try and make the fan as thin as possible and see how that help it. it is worth trying different setups to see if I can get it to work. than I can grab another one and make a dual setup. Well I finally cleared two cars out of my garage today and have some extra space I am going to put our little parts washer idea into works after last night I'm all amped up to get one of those up and going. that way I can have some nice clean heads shortly after the bench is finished. so much to do and not enough time. I love it. haha

Mark

Mark

- misc.motorsports

- Posts: 15

- Joined: Fri Feb 23, 2007 4:58 pm

- Location: lebanon, pa

Hello Mark, finally caught up with you. That is a fine looking flow bench you have there !

That blower is an interesting piece of gear, but it looks as though it is designed to flow a very large volume of air, but at relatively low pressure. I will try to guess what it may be capable of once it is mounted inside a blower box.

From my own measurements, I might suggest that rotor tip speed will be a fairly reliable indicator of developed pressure. Both the blowers I have here at the moment have 18" rotors compared to your 16" rotor. Your running speed is also rather low at only 1725 Rpm instead of the 2850 Rpm that is usual with 50Hz supply mains and a two pole motor.

So your diameter x speed = 16 x 1725 = 27,600

My diameter x speed = 18 x 2850 = 51,300

I can reach around very roughly seventeen inches developed pressure at "average" sorts of flow rates, maybe around half the maximum full open flow volume.

Now 51,300/27,600 is 1.86 times.

And pressure is proportional to tip speed squared.

So My pressure will be 1.86 x 1.86 = 3.46 times your likely pressure

My guess would be to expect something like 17" / 3.46 or about perhaps five inches of developed air pressure differential.

It will probably develop slightly more than that with completely blocked flow, maybe five and a half inches ? But we shall soon know for sure once that big boy is installed into a blower box.

A VFD will allow that motor to run at much higher rpm. 180 Hz will triple the motor Rpm, and pressure will rise around nine times to (???) 45"

As Anatolij says, up around 5,000 Rpm will be the range of speed required for a blower rotor of that diameter. I just hope both motor and rotor can structurally hold together, and the balance is reasonable.

One other problem is that tripling motor speed would require 27 times (3x3x3) the drive horsepower (81HP !) if you run that fan with full open airflow. If speeded up the air volume absolutely must be throttled, or both motor and fan will probably self destruct.

So in short, I believe that blower is just not going to develop sufficient pressure for your bench. Speeding it up is not really practical for strength and drive horsepower reasons. But try it first and see.

That blower is an interesting piece of gear, but it looks as though it is designed to flow a very large volume of air, but at relatively low pressure. I will try to guess what it may be capable of once it is mounted inside a blower box.

From my own measurements, I might suggest that rotor tip speed will be a fairly reliable indicator of developed pressure. Both the blowers I have here at the moment have 18" rotors compared to your 16" rotor. Your running speed is also rather low at only 1725 Rpm instead of the 2850 Rpm that is usual with 50Hz supply mains and a two pole motor.

So your diameter x speed = 16 x 1725 = 27,600

My diameter x speed = 18 x 2850 = 51,300

I can reach around very roughly seventeen inches developed pressure at "average" sorts of flow rates, maybe around half the maximum full open flow volume.

Now 51,300/27,600 is 1.86 times.

And pressure is proportional to tip speed squared.

So My pressure will be 1.86 x 1.86 = 3.46 times your likely pressure

My guess would be to expect something like 17" / 3.46 or about perhaps five inches of developed air pressure differential.

It will probably develop slightly more than that with completely blocked flow, maybe five and a half inches ? But we shall soon know for sure once that big boy is installed into a blower box.

A VFD will allow that motor to run at much higher rpm. 180 Hz will triple the motor Rpm, and pressure will rise around nine times to (???) 45"

As Anatolij says, up around 5,000 Rpm will be the range of speed required for a blower rotor of that diameter. I just hope both motor and rotor can structurally hold together, and the balance is reasonable.

One other problem is that tripling motor speed would require 27 times (3x3x3) the drive horsepower (81HP !) if you run that fan with full open airflow. If speeded up the air volume absolutely must be throttled, or both motor and fan will probably self destruct.

So in short, I believe that blower is just not going to develop sufficient pressure for your bench. Speeding it up is not really practical for strength and drive horsepower reasons. But try it first and see.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

ok I think I under stand what your saying. So if I understand this right If I run a 5hp motor at 3600rpm and make a big diameter wheel like 22inches it could be possible to to have close to 40 inches of air pressure differential. I;m not very good with the math stuff so let me know if I did this right.

your diameter speed = 18 x 2850 = 51,300

my new diameter speed = 22 x 3600 = 79,200

so 79,200/51,300 is 1.54 times

so my pressure would be 2.37 times your likely pressure

so would I expect to see close to 17 x 2.37 = 40.31 developed air pressure differential

like I said I'm not to great with my math but I think this is right. let me know if this might be a better route to go.

I am really learning alot about vfd's and motor restrictions this is all good stuff. Thanks

Mark

your diameter speed = 18 x 2850 = 51,300

my new diameter speed = 22 x 3600 = 79,200

so 79,200/51,300 is 1.54 times

so my pressure would be 2.37 times your likely pressure

so would I expect to see close to 17 x 2.37 = 40.31 developed air pressure differential

like I said I'm not to great with my math but I think this is right. let me know if this might be a better route to go.

I am really learning alot about vfd's and motor restrictions this is all good stuff. Thanks

Mark

- misc.motorsports

- Posts: 15

- Joined: Fri Feb 23, 2007 4:58 pm

- Location: lebanon, pa

My blower is 17,3 " in diameter , I made gaugings with different turns of the engine. Look my post "Anatoly blower bench" . For creation of depression there should be a certain speed of exhaust flow , and it depends from blowers diameter and engine RPM . All high pressure blowers have the increased diameter narrow blade . In your case as writes Tony, for reception of the necessary depression a minimum 30 " at your blowers widht , you will need to pump over much CFM, that will demand a lot of capacity. And even if to use the powerful engine, you hardly reach the necessary depression on 3000 RPM.

Anatoly

Anatoly

- riga team

- Posts: 112

- Joined: Sat Jan 14, 2006 2:05 pm

- Location: latvija

Yes Mark you have it.

The rotor times rpm figure (squared) will give a pretty good estimate for the pressure reached. Beyond that, the pressure will always fall off as the mass airflow through the blower increases. And that is entirely a result of all the cumulative pressure drops through the rotor and blower housing.

So you could say that, suppose a certain blower reached 35" pressure with completely blocked flow, but only reached 30" of pressure at 400 CFM. At 400 CFM it is actually losing that five inches because of internal flow restrictions within the blower itself.

You really need two things, enough diameter and rpm to develop the required pressure in the first place, and large enough internal flow paths to not lose much of that pressure over the required operating flow rate.

Another thought, if you doubled the diameter of the rotor, the circumference will also double. So let's assume a half inch wide rotor, the larger diameter rotor will have twice the internal flow area between the vanes, even though the width has not changed.

As Anatoly has just said, a high pressure blower will have a large diameter but narrow rotor. A low pressure blower will have a smaller diameter but much wider rotor for the same air flow volume.

So if you make yourself a large diameter wheel like 22 inches, it would not need to be made very wide to do the job, perhaps half an inch should be plenty.

For any given centrifugal blower there are some fairly fixed relationships.

Flow will increase directly with rpm. Double the speed, and you will pass twice the air volume.

Pressure increases with the square of rpm. Double the speed, and four times the pressure.

Horsepower rises with the cube of rpm. Double the speed requires eight times the drive horsepower. (twice flow x four times pressure)

Another interesting thing, drive power increases with mass air flow. If you get your blower running at full rpm and throttle the flow, motor current will fall as the mass flow is reduced. This sounds all wrong, but try blocking your shop vacuum cleaner, the motor definitely speeds up, you can hear it.

This has important implications for us. A commercial blower will nearly always be fitted with a motor that cannot be overloaded by the blower. The manufacturer has no idea what his blower is going to be used for, so the motor will be sized large enough to turn that blower with full open flow into zero back pressure.

If you then fitted that blower to a flow bench, it is always going to see at least thirty inches of back pressure (be quite highly throttled). So the motor will be running very lightly loaded under those conditions. If you fitted a VFD and speed up the blower, it can be made to develop more pressure and flow without overloading the existing motor. Just keep an eye on the motor amps. As long as the rated motor current is not exceeded, you can run it considerably faster.

This is what the shrouded rotor from a commercial high pressure blower looks like. This one is eighteen inches in diameter and only half an inch wide at the circumference. This is the type of extreme diameter to width ratio to be looking for in a suitable flow bench blower.

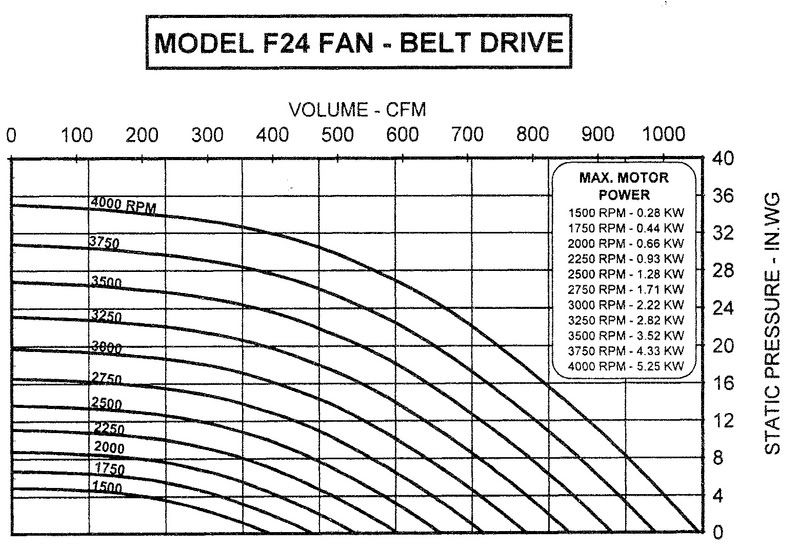

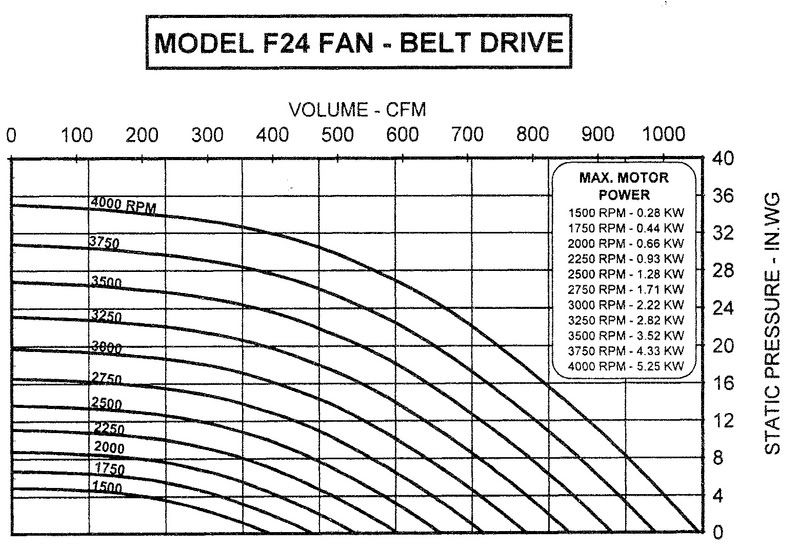

And here are the pressure and flow curves for that particular rotor.

The figures don't look that impressive, it originally came fitted with a 3Hp motor and was pulley driven at 3250 rpm developing 21 inches at 350 CFM.

But speeded up to around 5,000 Rpm with a 15Hp motor and VFD, it should really start to generate some serious airflow.

The rotor times rpm figure (squared) will give a pretty good estimate for the pressure reached. Beyond that, the pressure will always fall off as the mass airflow through the blower increases. And that is entirely a result of all the cumulative pressure drops through the rotor and blower housing.

So you could say that, suppose a certain blower reached 35" pressure with completely blocked flow, but only reached 30" of pressure at 400 CFM. At 400 CFM it is actually losing that five inches because of internal flow restrictions within the blower itself.

You really need two things, enough diameter and rpm to develop the required pressure in the first place, and large enough internal flow paths to not lose much of that pressure over the required operating flow rate.

Another thought, if you doubled the diameter of the rotor, the circumference will also double. So let's assume a half inch wide rotor, the larger diameter rotor will have twice the internal flow area between the vanes, even though the width has not changed.

As Anatoly has just said, a high pressure blower will have a large diameter but narrow rotor. A low pressure blower will have a smaller diameter but much wider rotor for the same air flow volume.

So if you make yourself a large diameter wheel like 22 inches, it would not need to be made very wide to do the job, perhaps half an inch should be plenty.

For any given centrifugal blower there are some fairly fixed relationships.

Flow will increase directly with rpm. Double the speed, and you will pass twice the air volume.

Pressure increases with the square of rpm. Double the speed, and four times the pressure.

Horsepower rises with the cube of rpm. Double the speed requires eight times the drive horsepower. (twice flow x four times pressure)

Another interesting thing, drive power increases with mass air flow. If you get your blower running at full rpm and throttle the flow, motor current will fall as the mass flow is reduced. This sounds all wrong, but try blocking your shop vacuum cleaner, the motor definitely speeds up, you can hear it.

This has important implications for us. A commercial blower will nearly always be fitted with a motor that cannot be overloaded by the blower. The manufacturer has no idea what his blower is going to be used for, so the motor will be sized large enough to turn that blower with full open flow into zero back pressure.

If you then fitted that blower to a flow bench, it is always going to see at least thirty inches of back pressure (be quite highly throttled). So the motor will be running very lightly loaded under those conditions. If you fitted a VFD and speed up the blower, it can be made to develop more pressure and flow without overloading the existing motor. Just keep an eye on the motor amps. As long as the rated motor current is not exceeded, you can run it considerably faster.

This is what the shrouded rotor from a commercial high pressure blower looks like. This one is eighteen inches in diameter and only half an inch wide at the circumference. This is the type of extreme diameter to width ratio to be looking for in a suitable flow bench blower.

And here are the pressure and flow curves for that particular rotor.

The figures don't look that impressive, it originally came fitted with a 3Hp motor and was pulley driven at 3250 rpm developing 21 inches at 350 CFM.

But speeded up to around 5,000 Rpm with a 15Hp motor and VFD, it should really start to generate some serious airflow.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

ok so I did some searching and some thinking last night and it seems like getting a blower all setup and working the way I want it is going to take some time. So for now I just ordered 4 of the surplus center motors to hold me over and get the bench up and running untill I have all the parts to play around with the blower.

I was searching around last night for some decent sized motors and I cam across a 10hp 200v 38amp 400hz 11,000 rpm motor dirt cheap ( I pretty much just had to pay to ship it) So I so started looking at vfd's and found one that will work with my 220v input and was adjustable from .5 to 400hz. hopefully I should have enough hp and rpm to get a blower wheel making enough pressure and volume.

Now I just have to save up for the VFD. It is only around $500 new with all the manuals and it says it can be controlled by a PWM so maybe I will get lucky enough to have the FP1 controll the VFD also. SO much more to learn and read, I could barely fall asleep last night trying to find ways to come up with money for the VFD. I am also going to order my FP1 sometime this week so hopefully I will be duing some crude tests and setup in the next week or two.

Well thats my update for now I will take more pics as soon as some of the parts start to get here.

Thanks Mark

I was searching around last night for some decent sized motors and I cam across a 10hp 200v 38amp 400hz 11,000 rpm motor dirt cheap ( I pretty much just had to pay to ship it) So I so started looking at vfd's and found one that will work with my 220v input and was adjustable from .5 to 400hz. hopefully I should have enough hp and rpm to get a blower wheel making enough pressure and volume.

Now I just have to save up for the VFD. It is only around $500 new with all the manuals and it says it can be controlled by a PWM so maybe I will get lucky enough to have the FP1 controll the VFD also. SO much more to learn and read, I could barely fall asleep last night trying to find ways to come up with money for the VFD. I am also going to order my FP1 sometime this week so hopefully I will be duing some crude tests and setup in the next week or two.

Well thats my update for now I will take more pics as soon as some of the parts start to get here.

Thanks Mark

- misc.motorsports

- Posts: 15

- Joined: Fri Feb 23, 2007 4:58 pm

- Location: lebanon, pa

I know the goal, or at least one of the goals was to use a blower fan to reduce the noise of the screaming vac motors. Has anyone considered what a large diameter blower will sound like at high RPMs??

Rusty

Race Car Design and Fabrication Forums

Race Car Design and Fabrication Forums

- rusty105

- Posts: 37

- Joined: Fri Jan 05, 2007 9:12 pm

- Location: NY

sound is not so much of my goal (although definitlly a plus) as much as my electric bill for enough vacuum to test my intake manifolds. I can't see running 8 or 10 vacuum motors at 8amps a piece. But never the less I bought four of them anyway to get me up and going. On a side note I got shafted on the 10hp motor I was going to get. They said they had 3 in stock I paid for it and the shipping and recieved an e-mail saying that their inventory was crewed up and they had no more. Bummer oh well more money to spend elswhere.

Mark

Mark

- misc.motorsports

- Posts: 15

- Joined: Fri Feb 23, 2007 4:58 pm

- Location: lebanon, pa

It is the motor that makes the noise not the blower with a vacuum cleaner.

Electric drills, routers, and vacuum cleaner motors all make that typical and very characteristic "appliance scream" because of the small high rpm brush type motors used.

A large commercial blower would run an induction motor similar (but larger) to the type used on your drill press. They run at much lower rpm, don't use brushes or a commutator, and are essentially completely silent. The only noise made by a big air blower is the roar from the air itself. It sounds a bit like the continuous roar from a large waterfall.

If the exhaust from the blower is vented outside, a really large flow bench makes about as much noise when running flat out as a small bedroom window air conditioner, at least on the suction side it does.

I have a professional quality sound level meter, and 60 to 65db at one metre is about the same as an average airconditionar, and about roughly the same sound pressure as normal conversational levels indoors.

Blow mode is always going to be much louder because of the direction of air movement.

Excessive noise is one very specific reason I would never again go back to using vacuum cleaner motors.

Electric drills, routers, and vacuum cleaner motors all make that typical and very characteristic "appliance scream" because of the small high rpm brush type motors used.

A large commercial blower would run an induction motor similar (but larger) to the type used on your drill press. They run at much lower rpm, don't use brushes or a commutator, and are essentially completely silent. The only noise made by a big air blower is the roar from the air itself. It sounds a bit like the continuous roar from a large waterfall.

If the exhaust from the blower is vented outside, a really large flow bench makes about as much noise when running flat out as a small bedroom window air conditioner, at least on the suction side it does.

I have a professional quality sound level meter, and 60 to 65db at one metre is about the same as an average airconditionar, and about roughly the same sound pressure as normal conversational levels indoors.

Blow mode is always going to be much louder because of the direction of air movement.

Excessive noise is one very specific reason I would never again go back to using vacuum cleaner motors.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

26 posts

• Page 2 of 2 • 1, 2

Return to Readers Flowbench projects

Who is online

Users browsing this forum: No registered users and 0 guests