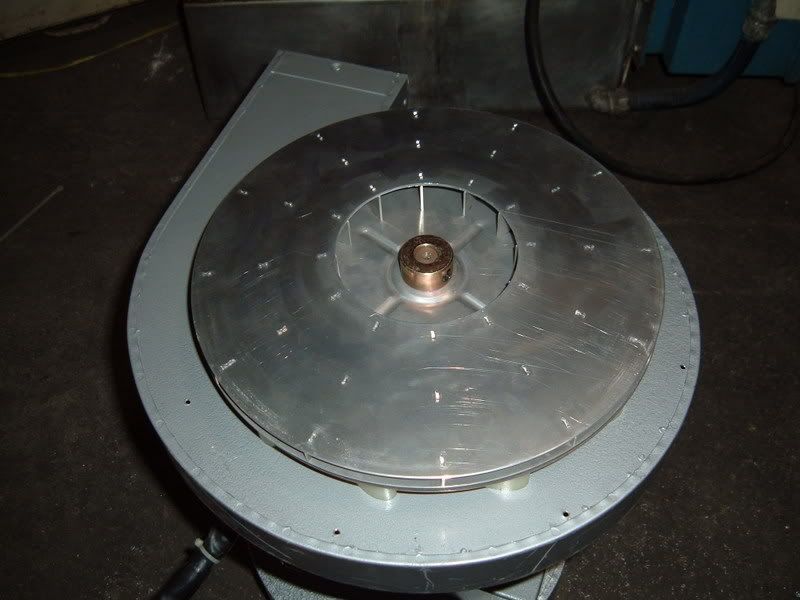

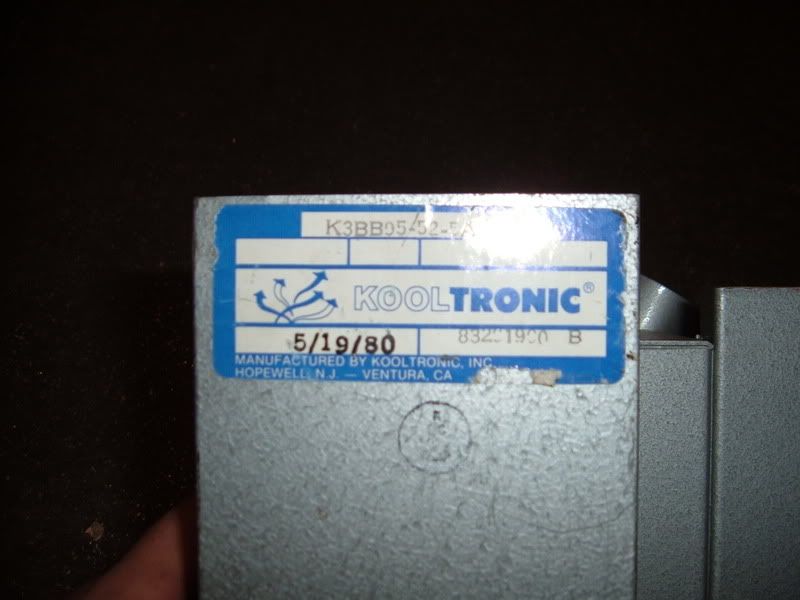

I've come across some interesting radial blade blowers at a local "Old Industrial Junk" house, which I'm very optimistic about. They are made by a company called Kooltronic. I took a bunch of pictures, so I'll start with that-

I hope that's not too many pics for the board, if so just let me know and I'll turn them in to links.

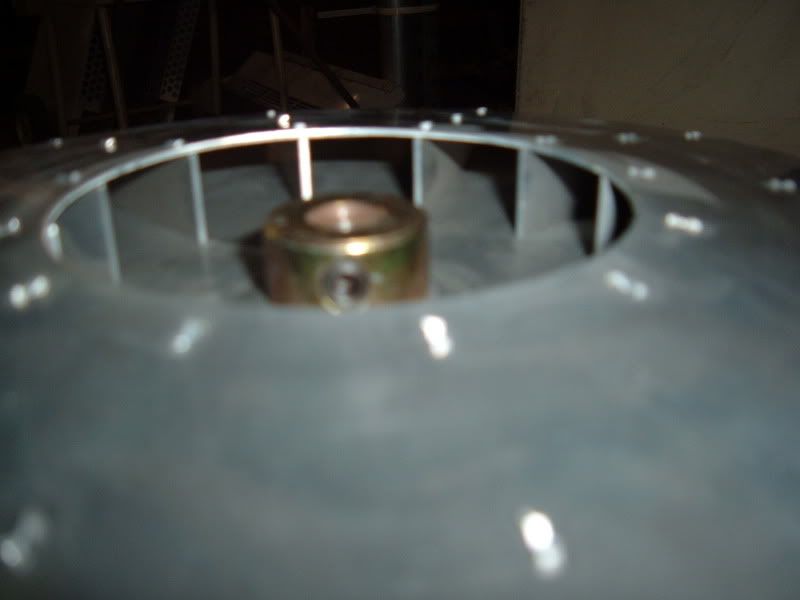

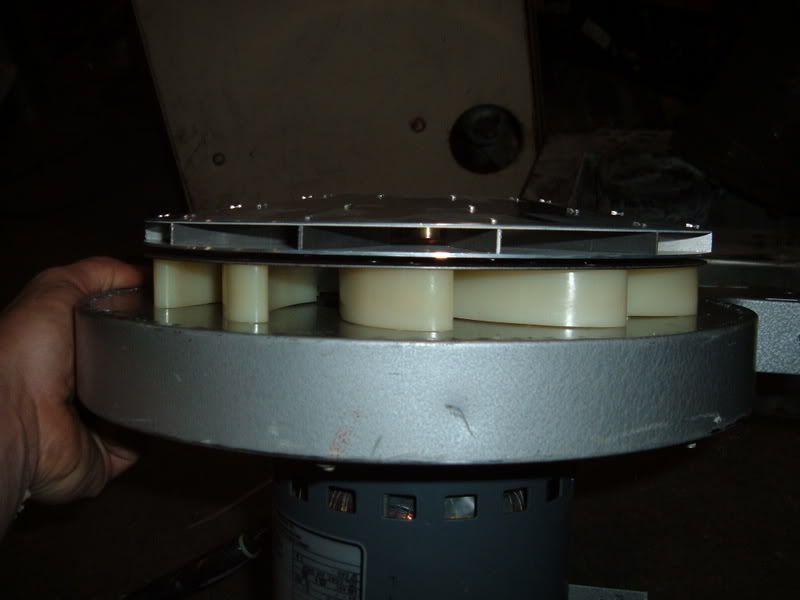

Anyhow, the pics pretty much tell the whole story. They're 2-stage blowers, as you can see in the pics the 1st wheel feeds in to the 2nd wheel. The wheels are 10'' diameter, ~3.75'' inlet, and 12 straight blades. Motor is 1/2hp 230v 3phase 3450rpm. The other side of the motor has a centrifugal "squirrel cage" type blower on it which I've gathered is no good for our application, so it is irrelevant and would not be used (more on that later).

I've found some information at the Kooltronic website, although there is nothing that matches up exactly to what I've found. The dimensions of the housing in this are the same as the housings I've found, though the part #'s are different and obviously they only show a single stage blower.

In my mind, the design of this blower will nearly double the pressure capability of a single, while flow will stay essentially the same. Is my thinking correct? I'm a newb so take it easy on me :laugh:

Going by the numbers at the Kooltronic site (don't know if they are correct), I am thinking I will need 4 of these blowers (8 wheels) to get a capacity that I'm happy with @ 3450rpm. Increased rpm.....??

My current idea is to use 2 motors to drive 2 housings each. I will take off the "squirrel cage" blower from the opposite side and mount the radial blade blowers, making the necessary changes for the housing to work correctly with "reverse" rotation.

So my question is; what do you guys think? Are these feasible? How do you think they'll perform?

Thank you for any advice you may have!