200 CFM Research

Tested today at VMP and glad to report that the 330 motor and head work are showing great progress. So much so that I am content at leaving the heads where they are from the above posted bench work. In preparation for today I jetted up one step 74/86 to guard against any lean and reset the gating for 6.5 lbs opening lift which I estimated should regulate pressure around 7-8 once the springs in the gate got supper hot. Took the tires down to 10.5 lbs from last weeks 12.5. Set two new records and here is the data results.

Run 1:

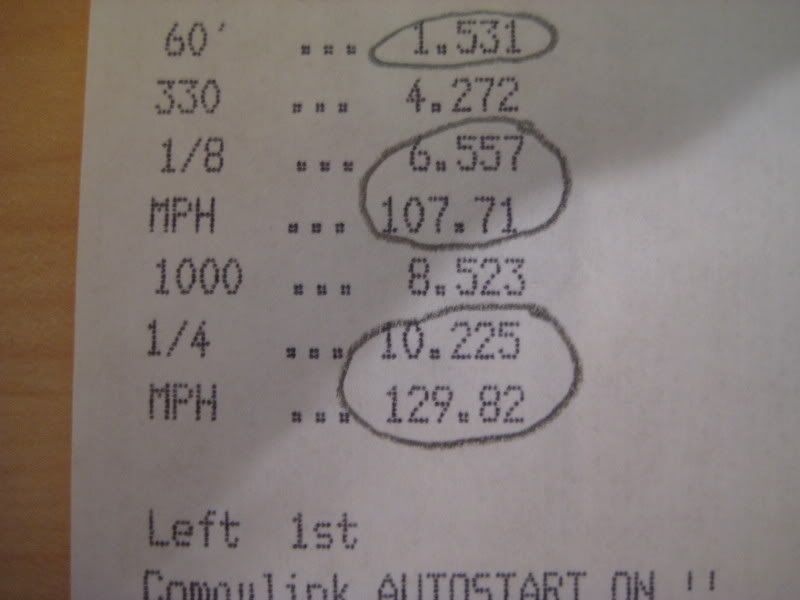

1.531 4.272 6.557 @ 107.71 8.523 10.225 @ 129.82

Had some slip and hop off the line from poor burn out. It jumped over to the right some so had to pull it back. Video shows it launched at 6 lbs and fluttered some from the hop. Made the shift at 5400. Averaged 8 lbs boost for most of the pull and was getting 10 lbs creep up boost on the top end charge. Before the line though, the tach was over 6,000 and I sensed the motor lay down or stop pulling as if the valves were floating. And I could sense the angled side winds which rocked the car some. I stayed in it with a slight backout which didn't seem to hurt the mph any. Here is the ticket and video for Larry M to evaluate. I put my know data in Pipemax and the mph seems down in relation to the total et at the eigth and 1000 ft point.

Larry M, here is the weather data from VMP for this run.

Temp @ 39.2, hum @ 28%, Bp @ 30.49, wind 9.2 mph from WNW at 45 degrees. Track runs due west.

elevation 1200 ft if I recall. Trans is powerglide, TCI street fighter converter, stall rpm 3400, rear dana 60 @ 4.56, tires 33.5 X 14 X 15, race weight 2575 lbs, (scales were closed but the extra turbo stuff adds a good 20 lbs over last known weigh in). Wheelbase at 109",

Run 1:

1.531 4.272 6.557 @ 107.71 8.523 10.225 @ 129.82

Had some slip and hop off the line from poor burn out. It jumped over to the right some so had to pull it back. Video shows it launched at 6 lbs and fluttered some from the hop. Made the shift at 5400. Averaged 8 lbs boost for most of the pull and was getting 10 lbs creep up boost on the top end charge. Before the line though, the tach was over 6,000 and I sensed the motor lay down or stop pulling as if the valves were floating. And I could sense the angled side winds which rocked the car some. I stayed in it with a slight backout which didn't seem to hurt the mph any. Here is the ticket and video for Larry M to evaluate. I put my know data in Pipemax and the mph seems down in relation to the total et at the eigth and 1000 ft point.

Larry M, here is the weather data from VMP for this run.

Temp @ 39.2, hum @ 28%, Bp @ 30.49, wind 9.2 mph from WNW at 45 degrees. Track runs due west.

elevation 1200 ft if I recall. Trans is powerglide, TCI street fighter converter, stall rpm 3400, rear dana 60 @ 4.56, tires 33.5 X 14 X 15, race weight 2575 lbs, (scales were closed but the extra turbo stuff adds a good 20 lbs over last known weigh in). Wheelbase at 109",

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

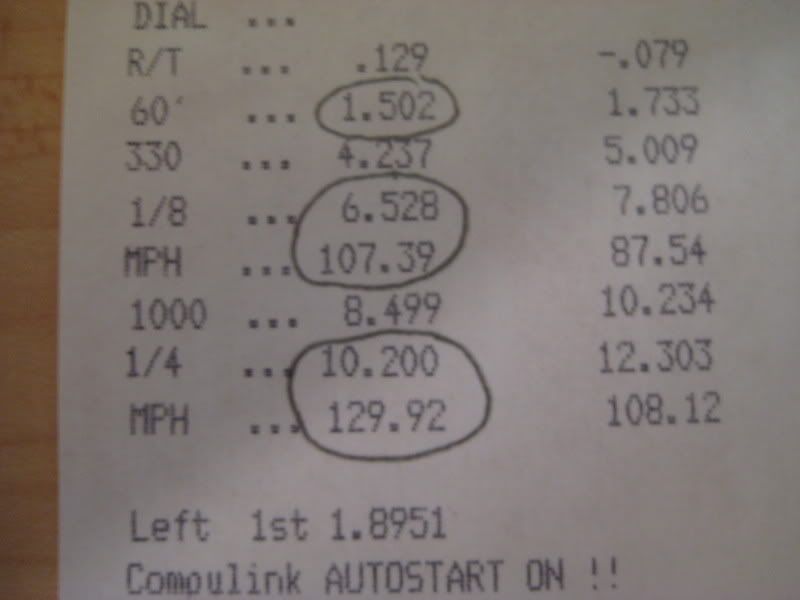

Here is the time slip for run # 1

Run # 2 was made with no changes. Got a much better burn out and the car left with no slip or fuss. Unforunately the video remote didn't activate properly and failed to get a video of the gauges. Top end was smooth on this run with no side wind to contend with, but the the rpm fell over once it got above 6,000 plus as if the valves were floating or as if the rpm limiter (chip is 6400) was holding it back. Just didn't pull any more and it was a good 150 ft plus from the line.

Run # 2 times are:

1.502 4.237 6.528 @ 107.39 8.499 10.200 @ 129.92

Track weather data: temp @ 41, humidity @ 26 %, Bp @ 30.47, winds from the west @ 5.8 mph.

Run # 2 was made with no changes. Got a much better burn out and the car left with no slip or fuss. Unforunately the video remote didn't activate properly and failed to get a video of the gauges. Top end was smooth on this run with no side wind to contend with, but the the rpm fell over once it got above 6,000 plus as if the valves were floating or as if the rpm limiter (chip is 6400) was holding it back. Just didn't pull any more and it was a good 150 ft plus from the line.

Run # 2 times are:

1.502 4.237 6.528 @ 107.39 8.499 10.200 @ 129.92

Track weather data: temp @ 41, humidity @ 26 %, Bp @ 30.47, winds from the west @ 5.8 mph.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

A couple of points, you state that your convertor is a 3400 rpm stall. You are making more power because if you watch the video it sure looks like the tach is right on 4000 rpm when you leave. Second point is I wonder if you are having the same problem my cousin had in his D/SA Camaro. The guy driving keep telling him the car at a miss and would not run above 6500 rpm in any gear. They had a 7500 rpm chip in the MSD rev limiter so they did not even think of that. My cousin finally decided to drive himself to see what was going on and he said it was the rev limiter not a miss. So he took the chip out or bypassed the rev limiter some way and the car went to 7500 no sweat. I have seen this happen a couple of times so if you do have a rev limiter check the chip. BTW and most important, nice runs!!!

John

John

- 106-1194218389

I see that. It held to 3400 with the lost 298 motor. Does it mean the converter is weaking or the torque is pulling it higher? It's a TCI street fighter and is not rated that high. Hope the converter is not going south. Yes, the chip is 6400 rpm rev limiter in the MSD 6A box. I think that's what I moved it too. It's either 6400 or 6200. Will check. I had that problem with the single Rajay 298 motor. Had a 6000 chip in the limiter and it started fading at around 5850 rpm. Larry M showed me the fade in ET Analyst feedback. Just hoping here it is not valve float on this solid roller. Springs are #977 Competition springs. I am going to try and run the data again in Pipemax and ET analyst. Last evening the predicted speeds in ETA were much higher at the finish for the same ET.

Still in thankful awe that it pulled this strong from the head work. I was concerned that the airspeeds were to high down the middle and over the SSR. And that the 175 to 180 max lift cfm would not be enough. I believe however the cylinders are getting a nice sinking charge judging from the boost levels. I have gain a new appreciation for air speeds in ports. And 30 degree backcuts on valves. Oh to be younger and wiser!

Still in thankful awe that it pulled this strong from the head work. I was concerned that the airspeeds were to high down the middle and over the SSR. And that the 175 to 180 max lift cfm would not be enough. I believe however the cylinders are getting a nice sinking charge judging from the boost levels. I have gain a new appreciation for air speeds in ports. And 30 degree backcuts on valves. Oh to be younger and wiser!

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Tom,

Torque converters will stall differently depending on what engine they are behind. If I put a torque converter behind my SBC and it stalled at 3400 rpm and then put it behind a 500 cid BBC it would stall much higher and be nothing wrong with the converter. Go to this link as TCI has a very good explaination of how a torque converter works and how to choose one. Also you will notice a link at the bottom where you can download this as a pdf file. I am going to do this as it is a nice reference article. Many of my friends have found a lot of time just in the converter. Keep in mind sometimes if you go to too much converter you can also over power the tires.

John

Torque converters will stall differently depending on what engine they are behind. If I put a torque converter behind my SBC and it stalled at 3400 rpm and then put it behind a 500 cid BBC it would stall much higher and be nothing wrong with the converter. Go to this link as TCI has a very good explaination of how a torque converter works and how to choose one. Also you will notice a link at the bottom where you can download this as a pdf file. I am going to do this as it is a nice reference article. Many of my friends have found a lot of time just in the converter. Keep in mind sometimes if you go to too much converter you can also over power the tires.

John

- 106-1194218389

200CFM

the 10.225 ET was approx negative - 443.04 Density Altitude

...but ETA doesn't allow negative DA inputs so i used 0.0 Feet

i'll change source code in ETS to allow up to negative

-2000 Feet when i have a chance.

the 10.200 ET run was at approx = negative - 302.6 DA

here's the ScreenShots

Notice-> somethings going on at 1320 Ft's MPH

the Rate of Acceleration is droping off in last 60 feet

as if you are on Rev-Limiter or letting off a little too soon

you should run past the Lights to get good accurate MPH data

the 10.225 ET was approx negative - 443.04 Density Altitude

...but ETA doesn't allow negative DA inputs so i used 0.0 Feet

i'll change source code in ETS to allow up to negative

-2000 Feet when i have a chance.

the 10.200 ET run was at approx = negative - 302.6 DA

here's the ScreenShots

Notice-> somethings going on at 1320 Ft's MPH

the Rate of Acceleration is droping off in last 60 feet

as if you are on Rev-Limiter or letting off a little too soon

you should run past the Lights to get good accurate MPH data

- maxracesoftware

- Posts: 132

- Joined: Fri Mar 26, 2004 7:54 pm

Thanks so much Larry M. My target goal of 500 hp has been met. That's a joy to know. The above 1200 ft elevation for VMP apparently is incorrect. I got that number while watching the Virginia Nationals on ESPN here and it came from the announcer who said the cars were racing at 1200 Density Altitude. Apparently that is not sea level but another factor calculation. I checked google and they show Richmond's heighest point at 250 ft above sea level, so VMP at best is 200 to 250 range I would guess.

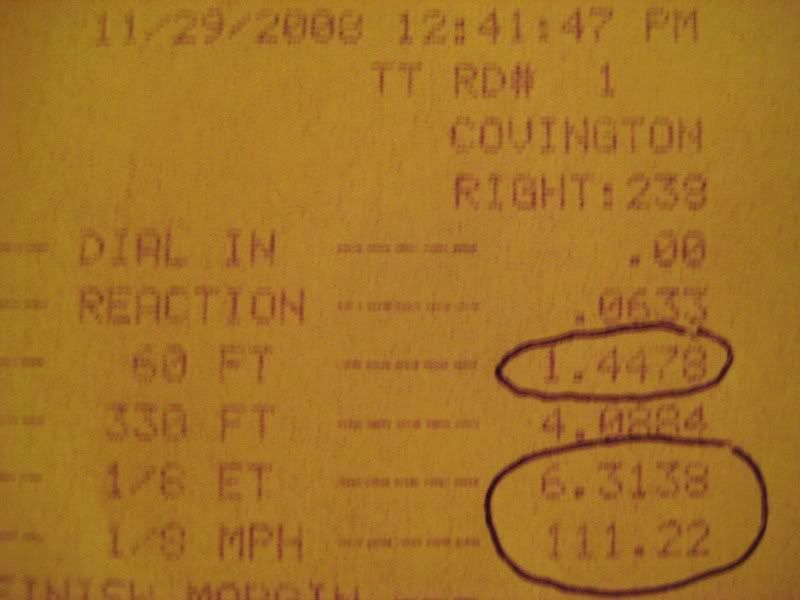

Now for the good news again. I raced yesterday in Top ET at Richmond Dragway 1/8 mile. And set three new records over last weeks VMP break in runs. Video recorder though did not offer any video data on the gauges though after each run. I was definitely seeing the REC icon in the screen but it was shutting down apprently on launch and not recording anything. Luckily I was glacing the boost meter across the line so got boost readings. But no shift, max rpm, or A/F readings. I left the jetting and timing the same. Did tighten one wastegate for a better balance to the other gate. They were crack opening the valve at 7 lbs test pressure. I was wanting to add 1 or 2 lbs more boost.

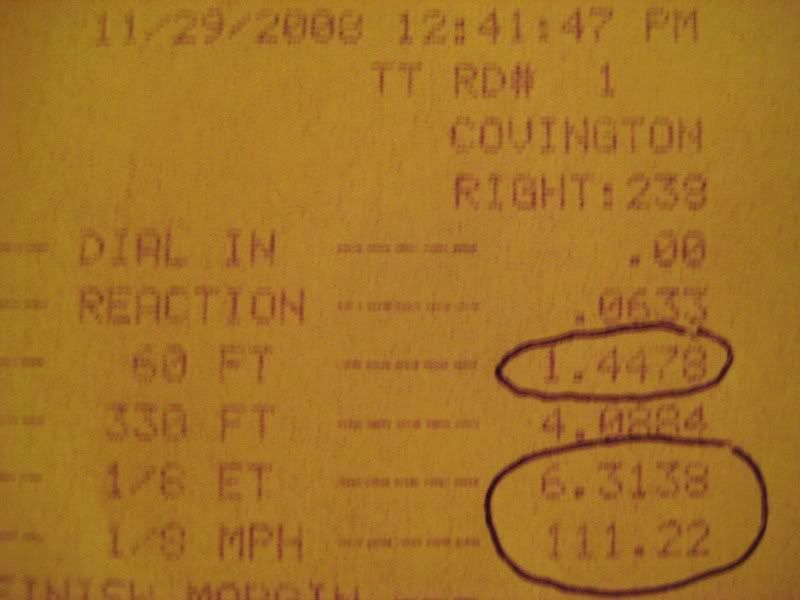

Run 1: 1.4478 4.0884 6.3138 @ 111.22

This was a new record for my stuff. Made the shift at same 5400-5500. And saw steady 10 lbs boost at the line.

Larry M. the air temperature from track weatherstation was:

Air @ 51 Hum @ 40 % Bp @ 29.78

Airport is 2.5 miles away and their on line data shows air @ 48.9. humidity @ 38 %, Bp @ 29.99. winds variable at 3.5 mph

Sea level elevation, lets estimate 225 ft. Here is the ticket from run 1.

Made a second run about an hour later. Slowed some but still better than at VMP.

Run 2: 1.4408 4.1071 6.3756 @ 109.25

Boost glance showed in 8-9 lb range so lost a good 1 lb of pressure. Track weather showed air @ 52 humidity @ 38 %, Bp @ 29.73 Airport data showed air @ 48.9, humidity @ 38 % , Bp @ 29.95, winds ESE @ 4.6 mph. Race track runs north.

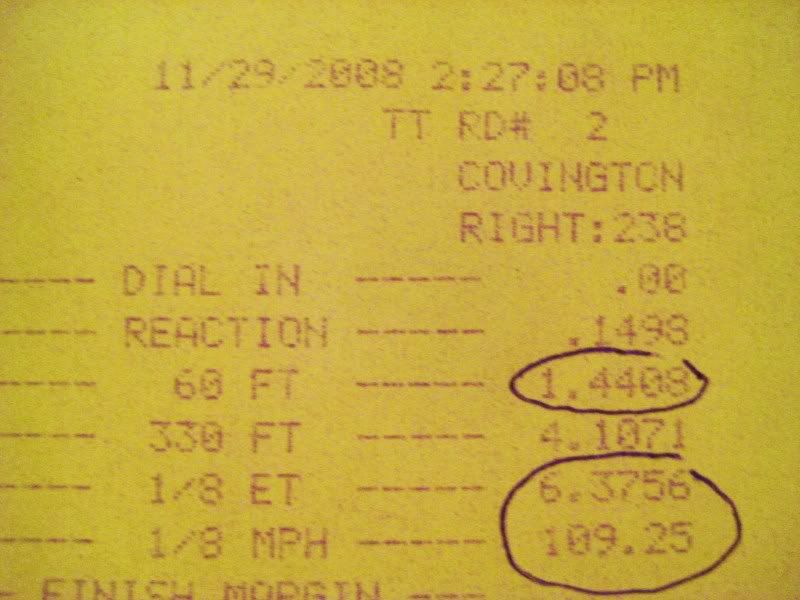

Here is second run data ticket.

Final run was eliminations and dialed 6.37.

Ran: 1.4308 4.1225, 6.4059 @ 107.89. Boost right at 8 lbs across the eight. Dragster wins on 4.8388 @ 140.76 My 60 ft time though was a new low for bite.

On load up I checked underneath with high beam spot light and the passenger side manifold exhaust gasket is leaking again just like before. Big soot print against the block paint. So the mph change is coming from that same problem area again.

Hoping now there are enough ponies to bag my first sub 10 sec ticket. Just not sure about the fueling capacity of this Mallory 110 EFI pump, or the valve float limit of 977-16 springs.

Should I be shifting at a higher rpm. How can I determine where the peak rpm hp is for the cam? If you know the weight of the piston and rods, is there a method to determine their safe rpm limit? Really worried about rpm above 6,000 on this motor. Should I be thinking of gearing it taller?

Now for the good news again. I raced yesterday in Top ET at Richmond Dragway 1/8 mile. And set three new records over last weeks VMP break in runs. Video recorder though did not offer any video data on the gauges though after each run. I was definitely seeing the REC icon in the screen but it was shutting down apprently on launch and not recording anything. Luckily I was glacing the boost meter across the line so got boost readings. But no shift, max rpm, or A/F readings. I left the jetting and timing the same. Did tighten one wastegate for a better balance to the other gate. They were crack opening the valve at 7 lbs test pressure. I was wanting to add 1 or 2 lbs more boost.

Run 1: 1.4478 4.0884 6.3138 @ 111.22

This was a new record for my stuff. Made the shift at same 5400-5500. And saw steady 10 lbs boost at the line.

Larry M. the air temperature from track weatherstation was:

Air @ 51 Hum @ 40 % Bp @ 29.78

Airport is 2.5 miles away and their on line data shows air @ 48.9. humidity @ 38 %, Bp @ 29.99. winds variable at 3.5 mph

Sea level elevation, lets estimate 225 ft. Here is the ticket from run 1.

Made a second run about an hour later. Slowed some but still better than at VMP.

Run 2: 1.4408 4.1071 6.3756 @ 109.25

Boost glance showed in 8-9 lb range so lost a good 1 lb of pressure. Track weather showed air @ 52 humidity @ 38 %, Bp @ 29.73 Airport data showed air @ 48.9, humidity @ 38 % , Bp @ 29.95, winds ESE @ 4.6 mph. Race track runs north.

Here is second run data ticket.

Final run was eliminations and dialed 6.37.

Ran: 1.4308 4.1225, 6.4059 @ 107.89. Boost right at 8 lbs across the eight. Dragster wins on 4.8388 @ 140.76 My 60 ft time though was a new low for bite.

On load up I checked underneath with high beam spot light and the passenger side manifold exhaust gasket is leaking again just like before. Big soot print against the block paint. So the mph change is coming from that same problem area again.

Hoping now there are enough ponies to bag my first sub 10 sec ticket. Just not sure about the fueling capacity of this Mallory 110 EFI pump, or the valve float limit of 977-16 springs.

Should I be shifting at a higher rpm. How can I determine where the peak rpm hp is for the cam? If you know the weight of the piston and rods, is there a method to determine their safe rpm limit? Really worried about rpm above 6,000 on this motor. Should I be thinking of gearing it taller?

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Pipemax gives you a general area of lobe rpm. I heard from other turbo guys that the motor makes power higher in the rpm range compared to NA in the same configuration. Is there any way to try a taller tire to test before a gear swap?

Chris Sikorski

- blaktopr

- Posts: 336

- Joined: Fri Mar 14, 2008 8:03 pm

- Location: New Jersey

Thanks Larry M. Appreciate the feedback. Engine and heads have exceeded my expectation. Never thought I would reach these power levels on this old stuff. Now I can move on to selecting a thicker wall block for the Howard rods and winter research on the "cut up red head." and hopefully put together a high boost motor for next year. They are offering test and tune this weekend but the weather is looking not fair.

Looking forward to Pipemax 4.0.

Looking forward to Pipemax 4.0.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Few weeks back I started the valve test enlargement on the cut up single chamber red head. Using the sioux valve stone grinder and new stones I enlarged the intake for 1.875 valve with 1.625 throat. Add a 45 seat with 60 below, 30 above and 15 toward the chamber wall. Blended up the bowl as best I could and layed back the chamber eyebrow walls. Took away most of the valve guide hump and added a second channel adjacent to the factory single vortex channel. With hours of back and forth grinding and testing it netted my best numbers so far.

lift cfm

.100---- 71.3

.200----129

.300----159.5

.350----169.3

.400----176.6

.450----182.1

.500----183.2

.550----186.8

.600----188.8

Down the middle it averages 286/320/305/320 fps

for 4 points from entry to SSR on a lift of .450" reference.

Here is the bowl and new channel and some filler to take out some casting pits.

I made a crude wet flow test and not sure how to interpret the photos. The method used was to flow at different lifts and note the display patterns. First lift shown here is at .100" with test pressure at full 28" wc. Fine mist spray dykem is sprayed into the port from a distance of about 6 inches from the radius entry. Container is a fine mist hair sprayer that makes a very nice fan shape spray. Spray sequence is 3 bursts of spray. I suspose if you were time the length it might combine to about 1.5 seconds. Not a lot of spray mist involved here.

The first observation I notice was the gathering of the spray mist together by the receiving air port that funneled and focus the spray toward the center of the entry port. It did this on each of the three separate bursts. I was expecting it to enter at all sections and areas of the radius port. It doesn't. The air flowing into the port sort of gathers the spray together and pulls it toward the center of the entrance port. You can see the spray becoming concentrated and lining up like a line of bees and diving pretty much into the center of the port entrance. There might be some concentrations entering on the sides and adjacent areas but to the eye the majority is going down the center. Has anyone else observed this behavior? Would this hold true for air/fuel going through an intake manifold port also?

Once into the port the only trail markings are to be found along the floor with a slight walk up the wall at about the head bolt turn. No trail markings are made on the roof or the side wall where the PRt is at. The photo gives the appearance of some on the roof but that is glare reflection from the floor. This also was a surprise. I was expecting to see trails everywhere and on all sections of the port walls but those areas are shinny clean. Now once it gets to the bowl area the dye reappears on the valve stem side facing the port. And it shows up again only on one half side of the bowl which faces primarily the spark plug and the chamber shroud side. Perhaps the photos can explain this better than words.

Here is the port and the floor and some of the wall shows the dye. There is no dye on the roof or PRT walls.

Here is the chamber markings. It exists toward the plug and around the chamber shroud area. This is only .100 lift here.

View with valve removed.

Some is trying to make it around the SSR. I see just a small marking along the rim.

Some is making it through the chamber shroud side. An exit line mark is where the pencil is pointed. Note how it runs the length of the shroud wall.

But very little seems to be existing from the SSR curve itself.

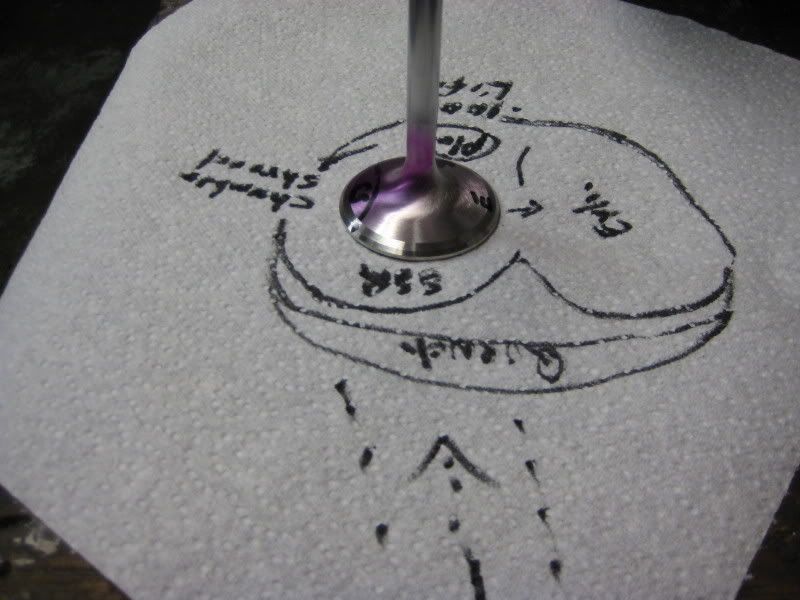

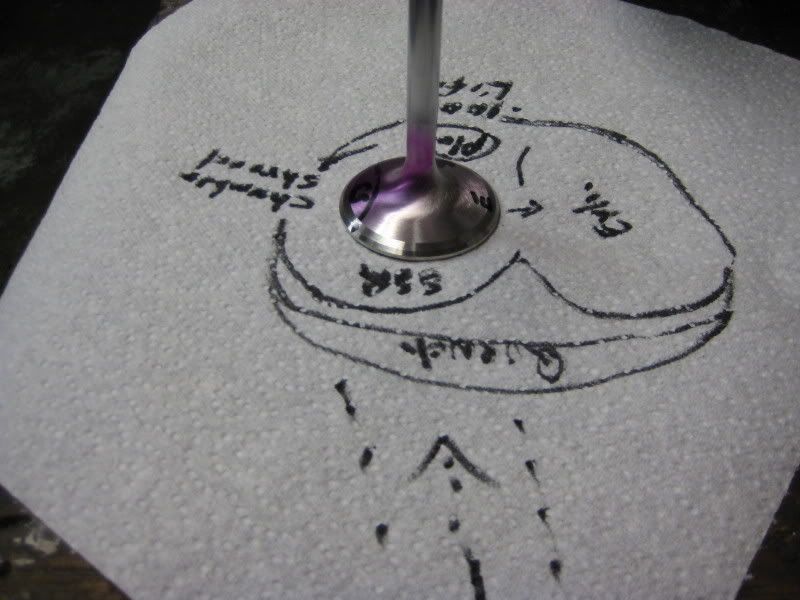

Here is the valve and I mapped it to give reference. Not the back of the valve stem marking facing the port and the clear exit which is toward the plug and some of the chamber shroud area. No markings towards the SSR side or any toward the Exhaust valve side which I thought was a better approach for the air. CS stands for chamber shroud section of the valve.

Another view of the valve and map.

What can one conclude from this test (if anything)? Here is what I didn't expect. (1) The down the middle path for the spray. (2) the bias toward the plug and only half of the bowl. (3) the shrouded wall markings on the chamber.

(4) the primary factory channel still dominating the direction.

(tom )

lift cfm

.100---- 71.3

.200----129

.300----159.5

.350----169.3

.400----176.6

.450----182.1

.500----183.2

.550----186.8

.600----188.8

Down the middle it averages 286/320/305/320 fps

for 4 points from entry to SSR on a lift of .450" reference.

Here is the bowl and new channel and some filler to take out some casting pits.

I made a crude wet flow test and not sure how to interpret the photos. The method used was to flow at different lifts and note the display patterns. First lift shown here is at .100" with test pressure at full 28" wc. Fine mist spray dykem is sprayed into the port from a distance of about 6 inches from the radius entry. Container is a fine mist hair sprayer that makes a very nice fan shape spray. Spray sequence is 3 bursts of spray. I suspose if you were time the length it might combine to about 1.5 seconds. Not a lot of spray mist involved here.

The first observation I notice was the gathering of the spray mist together by the receiving air port that funneled and focus the spray toward the center of the entry port. It did this on each of the three separate bursts. I was expecting it to enter at all sections and areas of the radius port. It doesn't. The air flowing into the port sort of gathers the spray together and pulls it toward the center of the entrance port. You can see the spray becoming concentrated and lining up like a line of bees and diving pretty much into the center of the port entrance. There might be some concentrations entering on the sides and adjacent areas but to the eye the majority is going down the center. Has anyone else observed this behavior? Would this hold true for air/fuel going through an intake manifold port also?

Once into the port the only trail markings are to be found along the floor with a slight walk up the wall at about the head bolt turn. No trail markings are made on the roof or the side wall where the PRt is at. The photo gives the appearance of some on the roof but that is glare reflection from the floor. This also was a surprise. I was expecting to see trails everywhere and on all sections of the port walls but those areas are shinny clean. Now once it gets to the bowl area the dye reappears on the valve stem side facing the port. And it shows up again only on one half side of the bowl which faces primarily the spark plug and the chamber shroud side. Perhaps the photos can explain this better than words.

Here is the port and the floor and some of the wall shows the dye. There is no dye on the roof or PRT walls.

Here is the chamber markings. It exists toward the plug and around the chamber shroud area. This is only .100 lift here.

View with valve removed.

Some is trying to make it around the SSR. I see just a small marking along the rim.

Some is making it through the chamber shroud side. An exit line mark is where the pencil is pointed. Note how it runs the length of the shroud wall.

But very little seems to be existing from the SSR curve itself.

Here is the valve and I mapped it to give reference. Not the back of the valve stem marking facing the port and the clear exit which is toward the plug and some of the chamber shroud area. No markings towards the SSR side or any toward the Exhaust valve side which I thought was a better approach for the air. CS stands for chamber shroud section of the valve.

Another view of the valve and map.

What can one conclude from this test (if anything)? Here is what I didn't expect. (1) The down the middle path for the spray. (2) the bias toward the plug and only half of the bowl. (3) the shrouded wall markings on the chamber.

(4) the primary factory channel still dominating the direction.

(tom )

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Who is online

Users browsing this forum: No registered users and 3 guests