Hey, I like that layout! Here is the quote from Barnhouse. "Round ports will flow more volume if the round port is straight and the CSA is constant. The minute that a turn occurs in a round port, the air will "glue in" harder against the bottom of the port turn and increase surface friction or drag. If this area is flatten out, the air will spread out, allowing more of the air to short cut the turn, thereby reducing boundary layer friction and increasing air flow through the turn."

How about this design. Use a round tube exhaust for the straight part and on any turns or bends use a flatter square wall for the turn in the exhaust. That would combine the best of both worlds. Would be interesting to flow bench the tubing on such a layout to see how the cfm is influenced.

Have you ever notice people post their exhaust valve flow data but I never see flow data for the same exhausting port with say the header or in my case the turbo plumbing attached. Yet the intake side is generally flowed with and without the intake manifold.

200 CFM Research

Long summer and trying to get back on the bench. Working on new heads for the new 298 motor that is still pending.

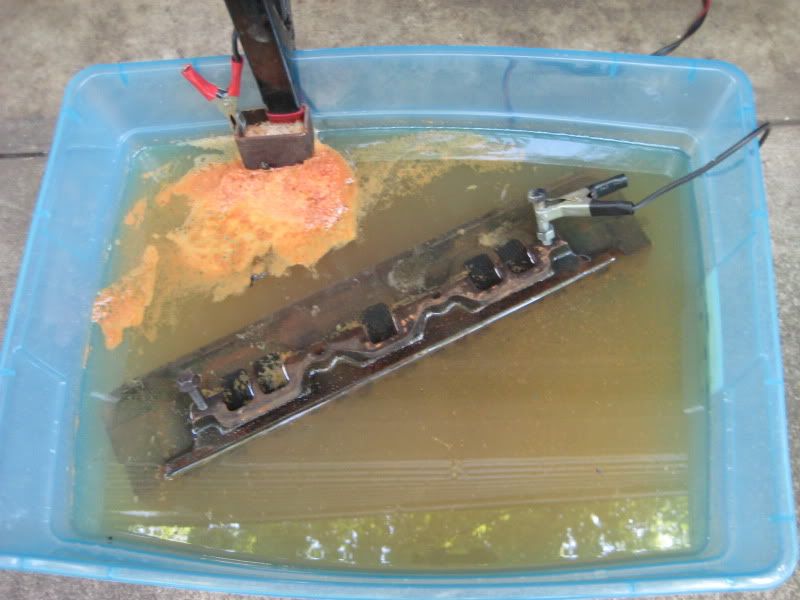

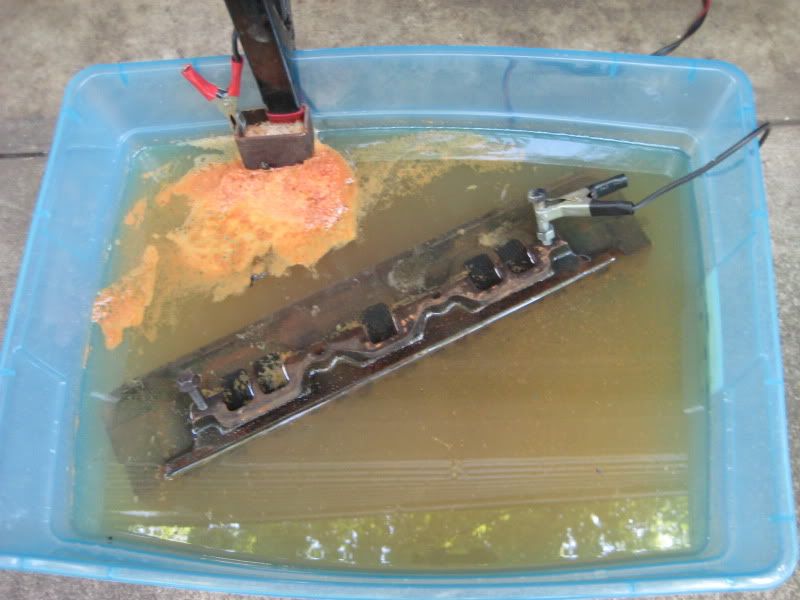

Here it is taking a bath in the garage.

Have started on one intake port. Here is the problem. I have no air speeds along the roof section. Very dead. Get plenty of fps along the floor and mid section but just dead along all the roof section. Never seen this on any of the other heads I have experimented on or raced. Could it be the pitot manometer? Shouldn't be because I get over 350 fps across the SSR. Maybe I am doing something wrong. Just surprised the roof is so dead or high in pressure zone to barely move the pitot fluid.

I can put my finger on the roof and sense no air pull. Put the finger along the floor and can sense the air pulling.

Anyone ever had a port roof to be slow. Seems impossible if I believe my eyes.

Here it is taking a bath in the garage.

Have started on one intake port. Here is the problem. I have no air speeds along the roof section. Very dead. Get plenty of fps along the floor and mid section but just dead along all the roof section. Never seen this on any of the other heads I have experimented on or raced. Could it be the pitot manometer? Shouldn't be because I get over 350 fps across the SSR. Maybe I am doing something wrong. Just surprised the roof is so dead or high in pressure zone to barely move the pitot fluid.

I can put my finger on the roof and sense no air pull. Put the finger along the floor and can sense the air pulling.

Anyone ever had a port roof to be slow. Seems impossible if I believe my eyes.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Doug,

To degrease and clean, Superclean spray works the best I've found so far.

To brighten after soda or glass basting.....I'm still open on that one. Sounds like the acid wash someone mentioned by be the ticket there.

Been told muriatic acid works but have never tried it.

To degrease and clean, Superclean spray works the best I've found so far.

To brighten after soda or glass basting.....I'm still open on that one. Sounds like the acid wash someone mentioned by be the ticket there.

Been told muriatic acid works but have never tried it.

- larrycavan

- Site Admin

- Posts: 1183

- Joined: Fri Apr 01, 2005 4:40 pm

Larry, Do you use the degreaser or the wheel cleaner? Of course, it really makes no difference as I never have time to actually CLEAN something, I just think I should! :p

Doug

Doug

I choose NOT to be an ordinary man because it is my right to be uncommon if I can! - unknown

- slracer

- Posts: 235

- Joined: Mon Sep 01, 2008 10:42 pm

The Super Clean is degreaser.

What's anybody got that will restore the brightness to cast aluminum after it's been blasted?

I see products out there advertised.

What's anybody got that will restore the brightness to cast aluminum after it's been blasted?

I see products out there advertised.

- larrycavan

- Site Admin

- Posts: 1183

- Joined: Fri Apr 01, 2005 4:40 pm

The acid alloy cleaner i use is actually called "Aluminium Cleaner" and is a sulphuric acid base so try not to get it in any cuts on your hands or breath the vapour cos it burns like #### either way!! Theres a company called 'Sierra Chemicals' that make the product, makes alloy shiney and new! :;):

- johno

- Posts: 65

- Joined: Sun Jul 19, 2009 8:07 am

- Location: Australia

Larry,

I use plain old Aluminum Jelly from the hardware store, then dilute it in distilled water about 20 to 1 it will give blasted AL that fresh cast look but gives the machined surface a sort of milky tone.

I have tried many acids BioKlean (Bike Magik Aluma-Kleen)makes one that does very well on good castings but if the alloy has to much Zinc it will black streak.

My latest project is an old dish washer with tank heater and recirc pump will use simple green and anti foam agent.

Rick

I use plain old Aluminum Jelly from the hardware store, then dilute it in distilled water about 20 to 1 it will give blasted AL that fresh cast look but gives the machined surface a sort of milky tone.

I have tried many acids BioKlean (Bike Magik Aluma-Kleen)makes one that does very well on good castings but if the alloy has to much Zinc it will black streak.

My latest project is an old dish washer with tank heater and recirc pump will use simple green and anti foam agent.

Rick

- 49-1183904562

Who is online

Users browsing this forum: No registered users and 2 guests