Help with transducers

11 posts

• Page 1 of 1

Why do you want to change the trancducers? Are they broken? If you cant calibrate the new ones, theres no real reason for it!

Isnt there any software or hardware calibration?

If the sensors output curves are identical, it should be possible to change them.

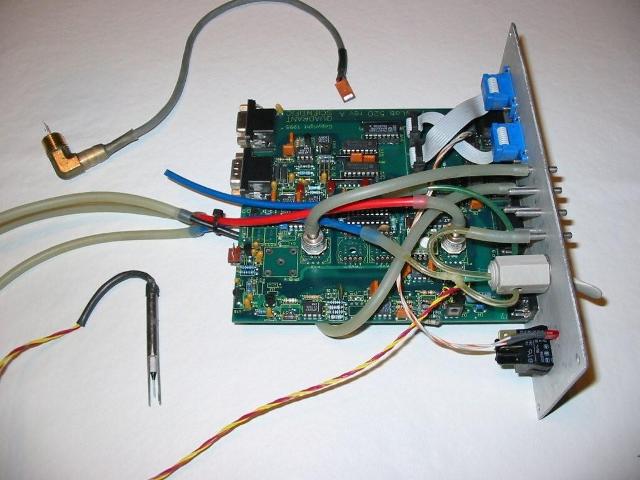

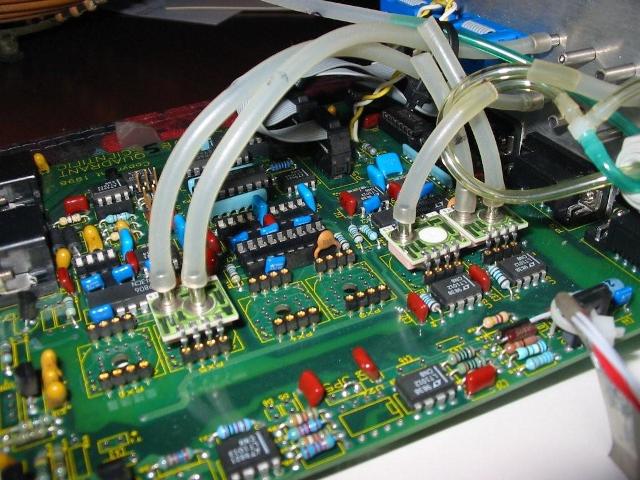

I assume that you have checked for leakage in the tubes going to the sensors? They dont look properly attached in the pictures?

Odd looking flow meter, it seems to be as in some cars mass air flow sensors.

Regards Gordon

Isnt there any software or hardware calibration?

If the sensors output curves are identical, it should be possible to change them.

I assume that you have checked for leakage in the tubes going to the sensors? They dont look properly attached in the pictures?

Odd looking flow meter, it seems to be as in some cars mass air flow sensors.

Regards Gordon

Mercedes Improver from Sweden

- GordonE

- Posts: 36

- Joined: Wed Dec 03, 2008 7:49 am

- Location: Sweden

All sorts of possibilities here.

But first, the calibration for both scale factor and zero, can either be done in hardware, or in software.

As I see no potentiometers or screwdriver adjustments anywhere on that circuit board, my guess is that all the calibration is done somehow in software.

The first thing to do is figure out how to adjust the thing so zero pressure reads zero, and full scale pressure also reads correctly.

Properly set up, it should then work o/k.

Unless..... The pressure transducers have been massively over pressured at some time and damaged.

And unless you run out of adjustment trying to get it to work right, the pressure transducers are probably o/k.

The problem with pressure transducers is there is no uniform standard. Every manufacturer does it "his" way. So if the exact make, model, and type number is no longer available, it may not be possible to find a substitute that will plug straight in and work identically to the original.

Something can probably be found to do the job after a lot of Mickey Mouse modifications.

A bit like putting a Chev engine in your Ford, possible, but it is not going to be a straight simple bolt in job for the inexperienced. And only the sort of job attempted as an absolute last resort.

But first, the calibration for both scale factor and zero, can either be done in hardware, or in software.

As I see no potentiometers or screwdriver adjustments anywhere on that circuit board, my guess is that all the calibration is done somehow in software.

The first thing to do is figure out how to adjust the thing so zero pressure reads zero, and full scale pressure also reads correctly.

Properly set up, it should then work o/k.

Unless..... The pressure transducers have been massively over pressured at some time and damaged.

And unless you run out of adjustment trying to get it to work right, the pressure transducers are probably o/k.

The problem with pressure transducers is there is no uniform standard. Every manufacturer does it "his" way. So if the exact make, model, and type number is no longer available, it may not be possible to find a substitute that will plug straight in and work identically to the original.

Something can probably be found to do the job after a lot of Mickey Mouse modifications.

A bit like putting a Chev engine in your Ford, possible, but it is not going to be a straight simple bolt in job for the inexperienced. And only the sort of job attempted as an absolute last resort.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

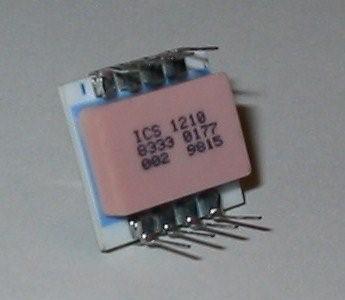

Thanks much for the feedback. I didn't know they were adjustable so I'll have to give this some thought. The pressure reads close to the same error with either board on the bench readout but the external pitot (for probing) goes whacky on the older board with the honeywell part. The digital readout goes up and down at random. I remember blowing into these in the past which may have hurt it. Also some saliva always gets in the tube when blowing into it. Don't know if that moisture would affect it. The newer ICS seems to be ok on that external probe. I understand what you are both saying about adjusting. I'll do more looking for that. There is a spreadsheet in explorer in the program to change the sensetivity of some of the modes of operation but I don't know which lines control what. There are probably a hundered lines with a lot of numbers on each. So Tony, you are saying the ICS sensors may not work on the older board or they may if I can find out how to adjust them? Anyone figure out what the flow sensor is or where it came from?

Jim

Jim

- Eagle Eye

- Posts: 27

- Joined: Sun Jan 25, 2009 9:22 pm

Looking at Bruce's reference, it appears the 1210 has only a 1 psi capability. That gives about 28" H2O, but overpressuring could have occured pretty easily. It also means be very careful when testing! -- Doug

I choose NOT to be an ordinary man because it is my right to be uncommon if I can! - unknown

- slracer

- Posts: 235

- Joined: Mon Sep 01, 2008 10:42 pm

Hello and thanks for the feedback. I'm confused about this website about the ics sensors. It looks to be only the information though and not the actual company that sells the product. Can anyone help me with that. Some good news though, it looks like they also make the earlier honeywell unit too.I ran across that by accident just scrollong thru the info. I'm still trying to find how to calibrate the sensors.I think thats the key to this whole thing. Jim

- Eagle Eye

- Posts: 27

- Joined: Sun Jan 25, 2009 9:22 pm

A quick search on Google shows this site:

Click the "View PCB Mounted" button and it lists all their sensors with pricing along all the engineering info you need for each sensor.

Click the "View PCB Mounted" button and it lists all their sensors with pricing along all the engineering info you need for each sensor.

"There is no more formidable adversary than one who perceives he has nothing to lose." - Gen. George S. Patton

- bruce

- Site Admin

- Posts: 1638

- Joined: Sun May 09, 2004 12:17 pm

That sensor is made by , poke around their website, there's more info available on the 1200 series of pressure sensors. If you still can't find all of the info you need, email them this picture and ask them about it.

BTW, sells the 2 psid version of that sensor for $36.58

BTW, sells the 2 psid version of that sensor for $36.58

- 86rocco1

- Posts: 292

- Joined: Sun Nov 18, 2007 5:46 pm

11 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 0 guests